TechnoNova s.r.o.

Our company is providing production of Pressure Devices, Vacuum Devices, Heat Exchangers, Tanks and Constructions and Devices.

Kontakt

TechnoNova s.r.o.

M.R.Štefánika 1

97271 Nováky, Slovakia

-

Show phone number

+421905531954

- Show Email

- www.technonova.sk

Contact Person

- Denisa Kanásová

-

CEO

-

Show phone number

+421905531954

- Show Email

Dipl.Ing. Ľuboš Šusta- Sales Manager

CEO / Chairman

Dipl.Ing. Denisa KanásováTurnover

4000000 EURVAT number

45372900Year of founding

2010Certifications

Quality Management certificate for production of pressure devices and equipment according to ISO 9001:2016 issued in 2019 by TÜV SÜD

License issued by TÜV Rheinland in 2013 for production of pressure devices according to EN ISO 3834-2, directive 97/23/EC and AD-Merkblatt HP0.

ASME Certificates (American Society of Mechanical Engineers)

Profile

Galerie

Manufacture and delivery of various pressure vessels, boilers, equipment and technological complexes for customers in Slovakia and abroad.

Containers, single- and double-walled containers made of carbon and stainless steel. According to customer requirements (volume, heating surface, pressure, temperature, medium) we also provide protection against the effects of chemically aggressive substances by means of rubber coating.

The areas where you can find our products are: pharmaceutical industry, chemical industry, oil and gas industry, paper industry

Business

Our company is providing production of Pressure Devices, Vacuum Devices, Heat Exchangers, Tanks and Constuktions and Devices. In this work we use the following technical procedures:

Welding

– welding of materials class 11, 12 ,17, aluminium and alloys, copper and alloys and titanium

– welding by methods ROZ, MIG, MAG – solid and tube rod and TIG

– fusion welding on semi-automatic machine

– flame welding

– positioning of welded pieces on various positioning devices and turning tables

Chipping machining

– lathe turning up to ? 1 250 mm, lathe turning on carrousels up to ? 3 300 mm, milling up to 440 x 1 400 x 450 mm,

– milling and drilling on horizontal drilling machines up to dimensions 2 000 x 2 000 x 1500 mm

– drilling ( drilling machines range VR – VR 6 )

– planning 1 600 x 10 000 x 1 600 mm, grinding of plane and cylindrical areas

– lathe turning on the new CNC machine LTC-35 CM

Shaping

– bands curling up to 80 x 80 mm and pipes up to ? 108 mm

– sheets curling up to thickness 25 mm

– sheets bending on edging press up to thickness 6 mm

– pressing on eccentric and hydraulic presses up to 70 t

Material cutting

– timber and profiles sawing on a band saw up to ? 350 and profile 3150 x 220 mm

– sheets cutting on oxygen-acetylen CNC machine up to thickness 300 mm

– plasma cutting by portable device up to thickness 28 mm

– sheets cutting by scissors up to thickness 25 mm, profiles cutting

Surface treatment

– areas sand blasting by steel grit in the chamber 3 000 x 2 550 x 10 000 mm, or in open space

– paint application by brush or by air spraying

Rubber coating

– vulcanizing in vulcanizing boilers up to ? 2 000 x 8 000 mm

– pressing of rubber parts in the mould

– surface and shaped rubber coating

Heat treatment

– annealing in the furnace 1 000 x 2 200 x 900 mm

Non-destructive tests

– defectoscopic testing of inner and outer defects by capillarity method and RTG radiation

– thickness measuring by ultrasonic thickness gauge

– flaws detection on rubber and plastic protection coatings by electro-sparking method

– pressure tests

– vacuum tests

Technological possibilities of our company are extended bycooperation with many companies.

Industry Focus

pharmaceutical industry, chemical industry, oil and gas industry, paper industry

Products/Services/Offers

Products/Services

Our Products

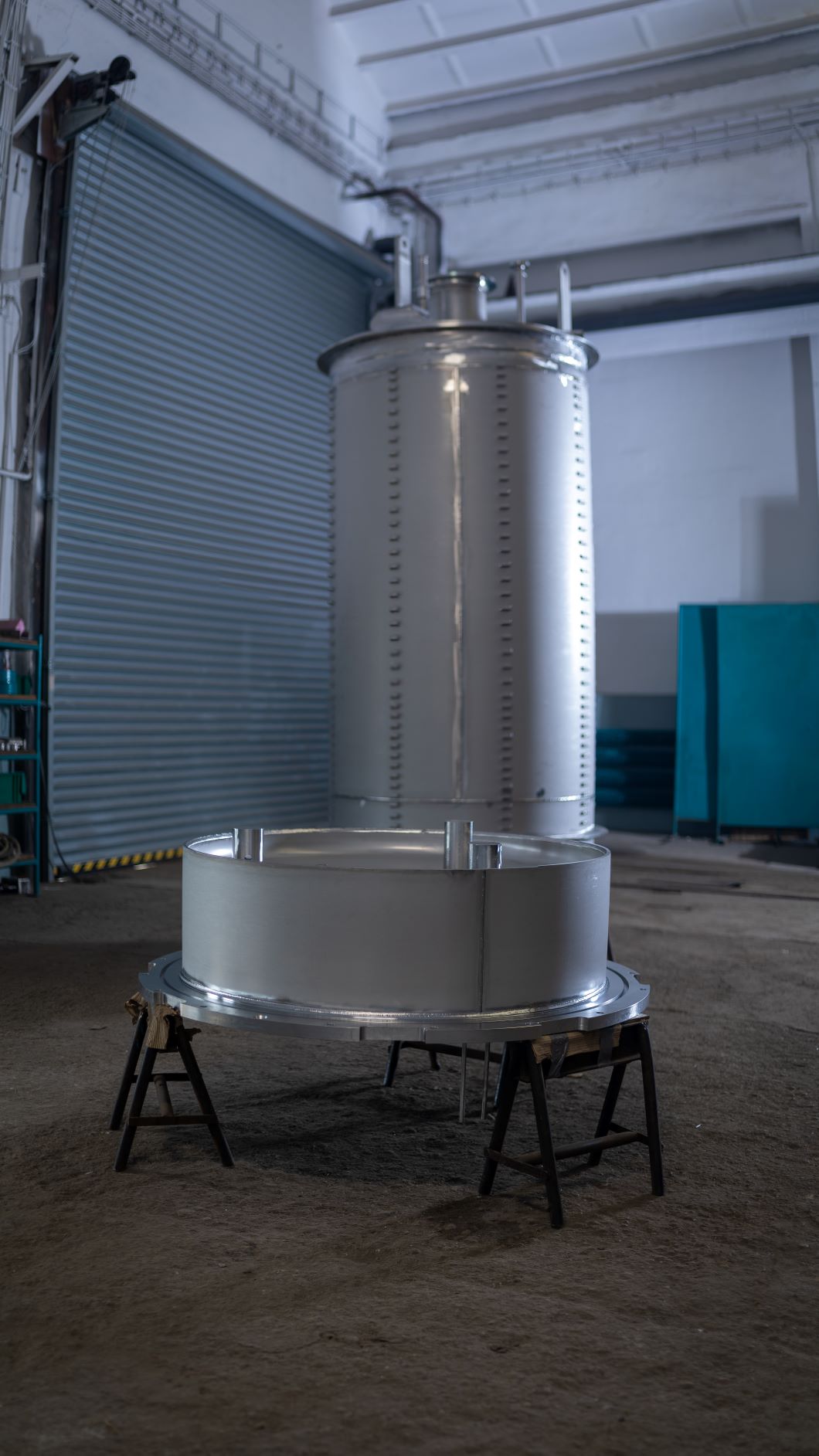

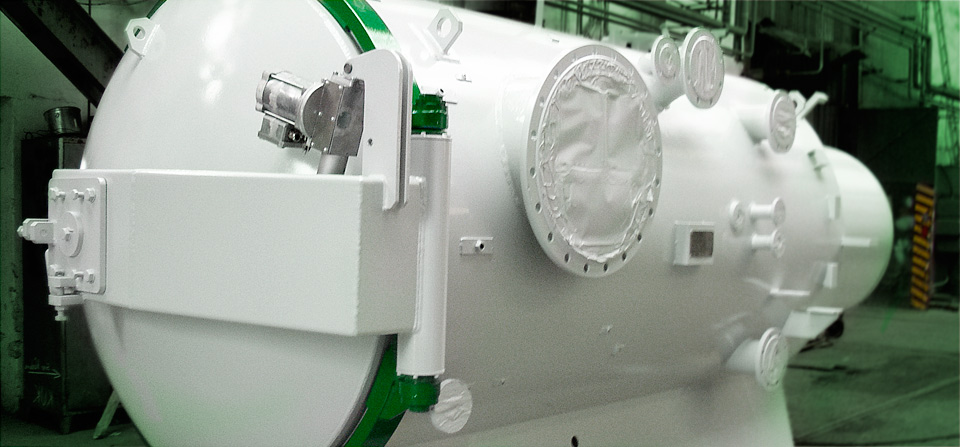

Our Products Pressure DevicesWe are fabricating horizontal and vertical tanks, single and double shell tanks, from stainless and carbon steel. According to requirements of the customer (capacity, heating area, pressure, medium), we provide protection against agresive chemicals by rubber coating. Vacuum DevicesSingle and double shell vacuum devices with dimensions and parameters according to customers requirements. Devices are fabricated from stainless and carbon steel. Heat ExchangersWe are producing also coolers, heaters, condensers, evaporators and all of their different combinations. TanksFabrication, inspections, repairs of steel railway cisterns with possibility of protecting rubber coating against chemicals. Constructions and DevicesDevices for energetic industry – industrial torches and parts of torches Devices for gas industry – filtering stations Moreover we fabricate industrial washers, devices for weaving of industrial textiles and different devices for chemical industry.

Offers

TechnoNova s.r.o. - Products/Services

Our company is providing production of Pressure Devices, Vacuum Devices, Heat Exchangers, Tanks and Constuktions and Devices. In this work we use the following technical procedures: Welding– welding of materials class 11, 12 ,17, aluminium and alloys, copper and alloys and titanium– welding by methods ROZ, MIG, MAG – solid and tube rod and TIG– fusion welding on semi-automatic machine– flame welding– positioning of welded pieces on various positioning devices and turning tables Chipping machining– lathe turning up to ? 1 250 mm, lathe turning on carrousels up to ? 3 300 mm, milling up to 440 x 1 400 x 450 mm,– milling and drilling on horizontal drilling machines up to dimensions 2 000 x 2 000 x 1500 mm– drilling ( drilling machines range VR – VR 6 )– planning 1 600 x 10 000 x 1 600 mm, grinding of plane and cylindrical areas– lathe turning on the new CNC machine LTC-35 CM Shaping– bands curling up to 80 x 80 mm and pipes up to ? 108 mm– sheets curling up to thickness 25 mm– sheets bending on edging press up to thickness 6 mm– pressing on eccentric and hydraulic presses up to 70 t Material cutting– timber and profiles sawing on a band saw up to ? 350 and profile 3150 x 220 mm– sheets cutting on oxygen-acetylen CNC machine up to thickness 300 mm– plasma cutting by portable device up to thickness 28 mm– sheets cutting by scissors up to thickness 25 mm, profiles cutting Surface treatment– areas sand blasting by steel grit in the chamber 3 000 x 2 550 x 10 000 mm, or in open space– paint application by brush or by air spraying Rubber coating– vulcanizing in vulcanizing boilers up to ? 2 000 x 8 000 mm– pressing of rubber parts in the mould– surface and shaped rubber coating Heat treatment– annealing in the furnace 1 000 x 2 200 x 900 mm Non-destructive tests– defectoscopic testing of inner and outer defects by capillarity method and RTG radiation– thickness measuring by ultrasonic thickness gauge– flaws detection on rubber and plastic protection coatings by electro-sparking method– pressure tests– vacuum tests Technological possibilities of our company are extended bycooperation with many companies.