MOULD SOLUTIONS S.R.L.

Design and manufacturing of moulds for plastic materials and moulding of plastic and thermosetting materials.

Kontakt

MOULD SOLUTIONS S.R.L.

Via Cristans, 8

33085 Maniago, Italy

-

Show phone number

+39 0427 709078

- Show Email

- www.mouldsolutions.it

Contact Person

- Luca Favetta

-

Show phone number

+393316706102

- Show Email

AHK Italy

Mrs. Barbara Maldari

Phone: +39 02 39800931 / +39 340 9624147

[email protected]

Profile

Galerie

Every task becomes creative when whoever does it takes care to do it well and improve it" (John Updike)

Mould Solutions came about in 2011 with the merging of two companies that had been in the mould sector in North-east of Italy for a long time: De Val Tecnostampi and Mould Service. De Val Tecnostampi was set up in 1978 as a small business to make injection and die-cast moulds. Its ideas, dedication, quality, and continuous growth allowed the Company to make its mark over time both nationally and internationally. It was a direct supplier to prestigious Tier 1 Clients, who are direct suppliers to the leading automobile manufacturers around the world.

The attention given to investing in technology, the know-how acquired, the innovation, and the search for an organisational structure able to guarantee the Client an all-round service led, in the ‘90s, to the setting up of Mould Service. This company specialised in testing inject moulds and moulding technical parts, mainly providing support for De Val Tecnostampi’s internal mould production, and later extending the service to others as well.

The recent idea to unite the two companies was based on market needs, in order to implement synergies and optimise resources, to continue to offer the clientele a product that is sound in technical and quality terms, with a view to development and continuity in the future. Today, Mould Solutions is a sound business with a staff of 40 people, and a production complex that covers more than 3,500 sq.m., with a man/machine production capacity of 7,000 hours per month.

Our current focus is on medium and large-size injection moulds for the Automotive sector, as well as multi-component moulds in general.

Business

Design

"Design is the process that deals with giving form to a solution. It is the technical art of solving problems"

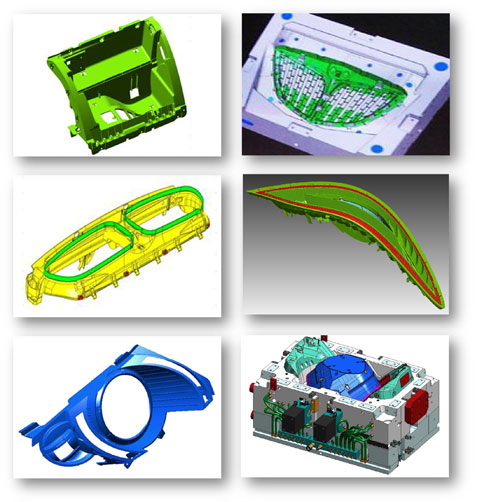

The staff in the technical department at Mould Solutions is made up of highly qualified and experienced personnel, in step with the ongoing development of the computer systems we use.

They are able to provide complete technical consultancy, whether working on designs developed in-house or provided by the Client: from a feasibility study to optimising each detail and through to subsequent execution of the entire project.

They use 5 workstations with CAD software for 2D - 3D (CatiA, ThinkDesign) design, and 5 CAM stations (WorkNc, Cimatron) for simulating and setting up tool paths.

Each project leader’s interaction with the client, is direct and managed using fast, secure data transmission systems.

Each project is looked after by the technical department, in all phases, from in-house manufacture, through to final testing of the mould.

Production

"Technological innovation is not a process: it is the means to achieve our goals"

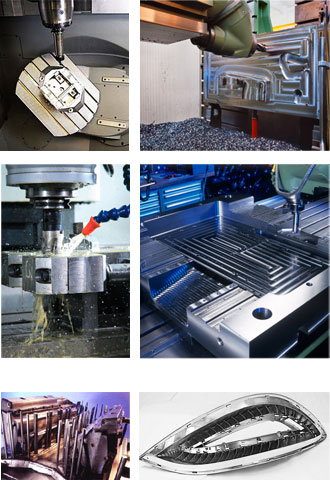

In addition to being made up of highly experienced, professional personnel, the production department at Mould solutions has modern machinery and equipment, and is up to date with the most recent technologies: 5-axis high-speed milling machines and pallet changer, wire cutting and wire EDM machines, numerically controlled drilling machines, spotting press and injection machine for mould testing and sample parts production. Mould Solutions can boast many years experience in making moulds for highly complex aesthetic components and technical parts, and besides the traditional mono colour/component we make: 2K bi-component rotative, blade or translation moulds (plastic + rubber), with 2-3- rotating colours, and gas injection moulds. Especially with reference to the Automotive sector, Mould Solutions is specialized in design and mould manufacturing for:

-Head and rear light units: multi K lenses and frames, reflectors and housings.

-Exterior aesthetic parts: frames and moulded parts.

-Interior aesthetic parts: side panels, trunk panels, handles, dashboards, stanchion covers, tunnels, and central consoles.

-Technical parts under-bonnet: air ducts, collectors, windscreens and bi-component covers in general.

Our approach to the IT and domestic appliance sectors is characterised by making medium and small size moulds, mainly for niche components and complex bi-component parts.

Video

Products/Services/Offers

Products/Services

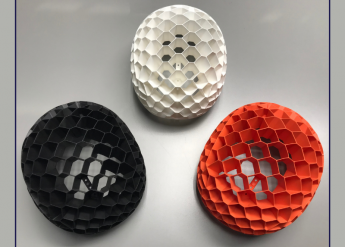

Component for Sports safety equipment

TPE molded component in house for Sports safety equipment. All moulds are manufactured by our internal toolshop.

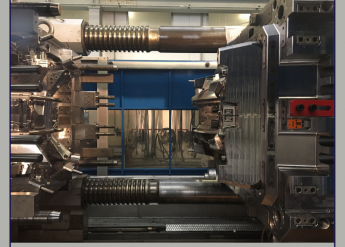

3k Injection Machine

Detail of 3K injection machine for moulds trial and pre-series production.

Component for Medical Devices

2K component for medical devices. Detail of surgical scalpel. All moulds are manufactured by our internal toolshop.

Offers

"One-Stop-Shop" model - MOULD SOLUTIONS complete Service from design through delivery of a mould

"The client is the most important element of our production cycle" (Edwards Deming) The “one-stop-shop” model adopted by Mould Solutions guarantees that Clients will have a complete service: from design through delivery of a mould tested in-house, “ready to produce”. Thanks to this prerogative, Mould Solutions has a moulding department where it tests moulds and produces sample parts. It is adaptable to its Clients’ needs, backed up by the experience of qualified technicians. Each injection machine is fitted with a robot for automatic pick-up and simulation of mass production. Every machine is equipped with rotative table and additional injection units for 2K/3K moulding. Besides its in-house support role, the moulding department offers a mould testing and sampling service for external toolmakers and produces prototypes or small lots.