Planimolde

Moulds & Plastics - Portuguese plastic injection mould maker since 1948 with broad experience in the design and construction of injection tools for different types of industries.

Kontakt

Planimolde

Rua do Lamarão da Embra - Pedrulheira

2430-119 Marinha Grande, Portugal

-

Show phone number

+351 244 574 850

- Show Email

- www.planimolde.pt

Contact Person

- SÓNIA MARTINS

-

Comercial e Gestora de Projeto

-

Show phone number

+351 963 718 050

Deutsch-Portugiesische Industrie-und Handelskammer / AHK Portugal

Helga Barreiros

Koordination Services | Abt. Markt- und Absatzberatung

Coordenadora de Serviços | Dpt. Consultoria de Mercado

Tel. +351 21 1211510 / 934 890 651

[email protected]

www.ccila-portugal.com

Turnover

6MOffices

Marinha GrandeYear of founding

1978Profile

Galerie

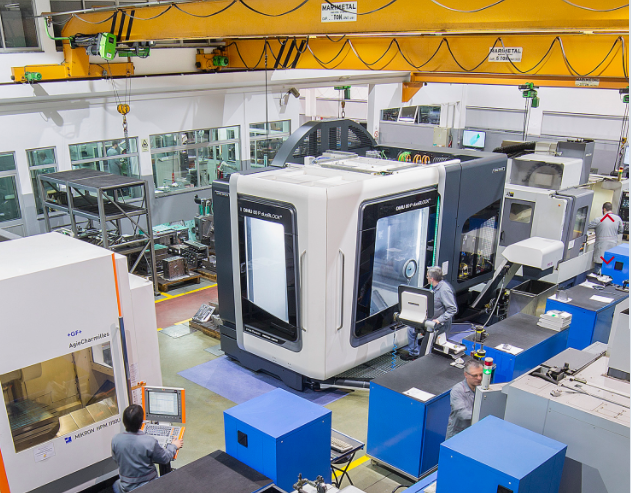

Planimolde is a Portuguese plastic injection mould maker, a small to medium size company, able to work on a project since the tool/article design till its first parts, all in-house, considering Tool Engineering (analysis of the tool’s concept & layout), Tool construction (CNC, EDM, Drilling, Grinding…), Project Management, Tool and Parts Measurement Control.

Since 2018 we are also able to run the mould trials internally thanks to our new injection unit with 3 Engel Machines (2K 500T, 300T & 160T) and one Cleanroom with a 280T Engel Machine.

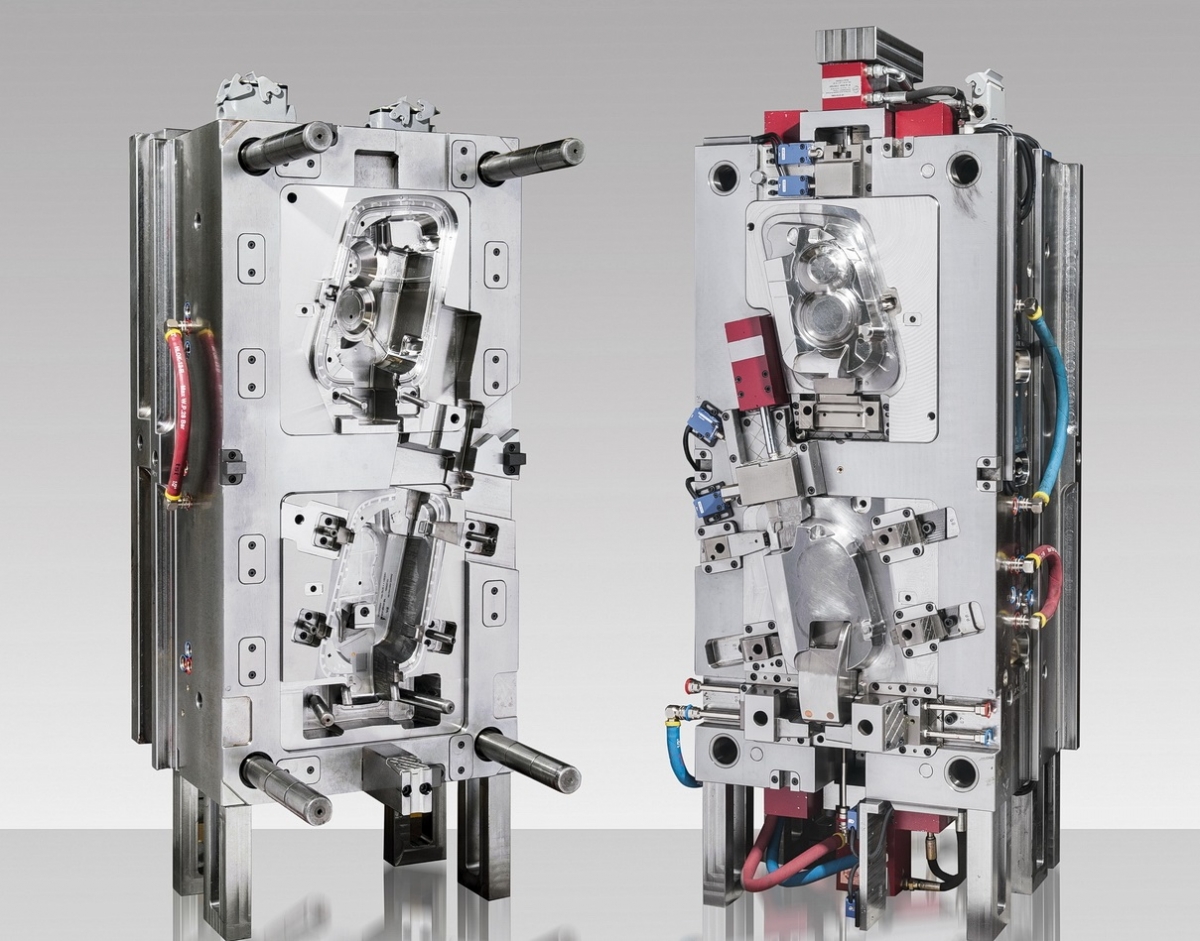

We are specialized in several types of tools as stackmoulds, multicavities, overmoulding, 2K & 3K, among other technologies for different industries,

Planimolde is actually one of the oldest companies in the region, with 42 years of a wide experience in several areas and technologies. It has always held a strong position in the Portuguese Mould Making Industry, being one of the first Portuguese tool makers to have its Quality System certified according to ISO9001 back in 1993.

We see ourselves as a company always open to cooperate with our clients, working closely together, and in this way being able to meet their growing requirements and reaching a stable growth over so many year.

Business

Services

- DEVELOPMENT AND DESIGN OF PLASTIC PARTS

- MOULD-FLOW AND BENDING ANALYSIS

- MANUFACTURING OF PROTOTYPE TOOLS

- MANUFACTURING OF PRODUCTION TOOLS

- TOOL AND PLASTIC PARTS METROLOGY

- PRODUCTION OF PLASTIC PARTS

Products

FULL-FACE SHIELD

Full-Face Protection;

Disinfection & Shattering Resistance;

Adjustable, Maximum Comfort;

SAFETY GOGGLES

Side Protection;

Excellent Eye Protection;

Protection from Splashes & Aerosols;

Maximum Comfort;

Wearable with medical glasses;

Industry Focus

Target Industries:

- Automotive 82%

- Housewares 5%

- Electrics 4%

- Packaging 3%

- Others 6%

Downloads

Video

Products/Services/Offers

Products/Services

Full-Face shield

Developed and produced internally Side Protection; Excellent Eye Protection; Protection from Splashes & Aerosols; Maximum Comfort; Wearable with medical glasses;

Protection Goggles

Developed and produced internally Full-Face Protection; Disinfection & Shattering Resistance; Adjustable, Maximum Comfor

Offers

BEST CRANK

This crank is machined in aluminium and titanium alloys, weights up to 500g, has a flexible configuration for road and mountain and is resistant enough to endure 50.000 cycles (with 1800N of load) according to the ISO 4210:2014. The focus of this project was the study and comparison of different materials, geometries, implicated processes and methodologies with the view of developing a DESIGN crank unit that could maximize RESISTANCE. BestCrank unit was the result. The BestCrank stands out with its high ratio of PERFORMANCE, WEIGHT and EXCLUSIVITY. More...