Promecel, Lda.

Located in Braga, Portugal, Promecel is a private capital company whose markets are divided by the electrical sector and the mechanical components sector. It was founded in May 1985, and soon the quality and rigor assumed a major importance in becoming a reference in the metalworking industry. Our customers come from the most different activity sectors namely Agriculture, Hydraulics, Automobile Industry, Railways, Naval Industry, Shoe Manufacturing, Medicine, Hunting Weapons, Military, Aeronautical, Electrical, and others. The company is composed by five producing sectors that, when needed, work together to obtain the final product as required by the customer. The five sectors are: Precision Machining, Foundry, Stamping, Electroplating and the Manual Assembly Line.

Kontakt

Promecel, Lda.

Parque industrial de Adaúfe, pav. k1

4710-593 Braga, Portugal

-

Show phone number

+351253307040

- Show Email

- www.promecel.pt

Contact Person

- Jose Manuel Silva

-

General Manager

-

Show phone number

+351938020301

- Show Email

Ana Gomes (Comercial) - [email protected]

Frederico Jacob (Production Manager) - [email protected]

Eliana Lopes (Quality and Environment Manager) - [email protected]

CEO / Chairman

José Manuel Peixoto SilvaTurnover

7.100.000€VAT number

PT501531645Offices

1 plant with the production unit and headquartersParticipation in Exhibitions

Midest (France) Elmia (Sweden); Hi (Denmark); IMTS (USA)Year of founding

1985References

Optotech

Schenck Process

Leica

Inventron

Triumph Group

Manitowoc

Senvion

Silvadec

Sunviauto

Galland

ECCO

Delabie

Browning

Sahleduc

Balanças Marques

Certifications

ISO 9001:2015

ISO 14001:2015

Authorization for production of Militar parts

Profile

Galerie

Promecel is a private capital company whose markets are divided by the electrical sector and the mechanical components sector. It was founded in May 1985, and soon the quality and rigor assumed a major importance in becoming a reference in the metalworking industry.

A clear bet in the foreign markets of outstanding technical requirements as demanded from Promecel the most advanced means of production and control, as well as 90 employees with the highest specialization levels.

Our customers come from the most different activity sectors namely Agriculture, Hydraulics, Automobile Industry, Railways, Naval Industry, Shoe Manufacturing, Medicine, Hunting Weapons, Military, Aeronautical, Electrical, and others.

The company is composed by five producing sectors that, when needed, work together to obtain the final product as required by the customer. The five sectors are: Precision Machining, Foundry, Stamping, Electroplating and the Manual Assembly Line.

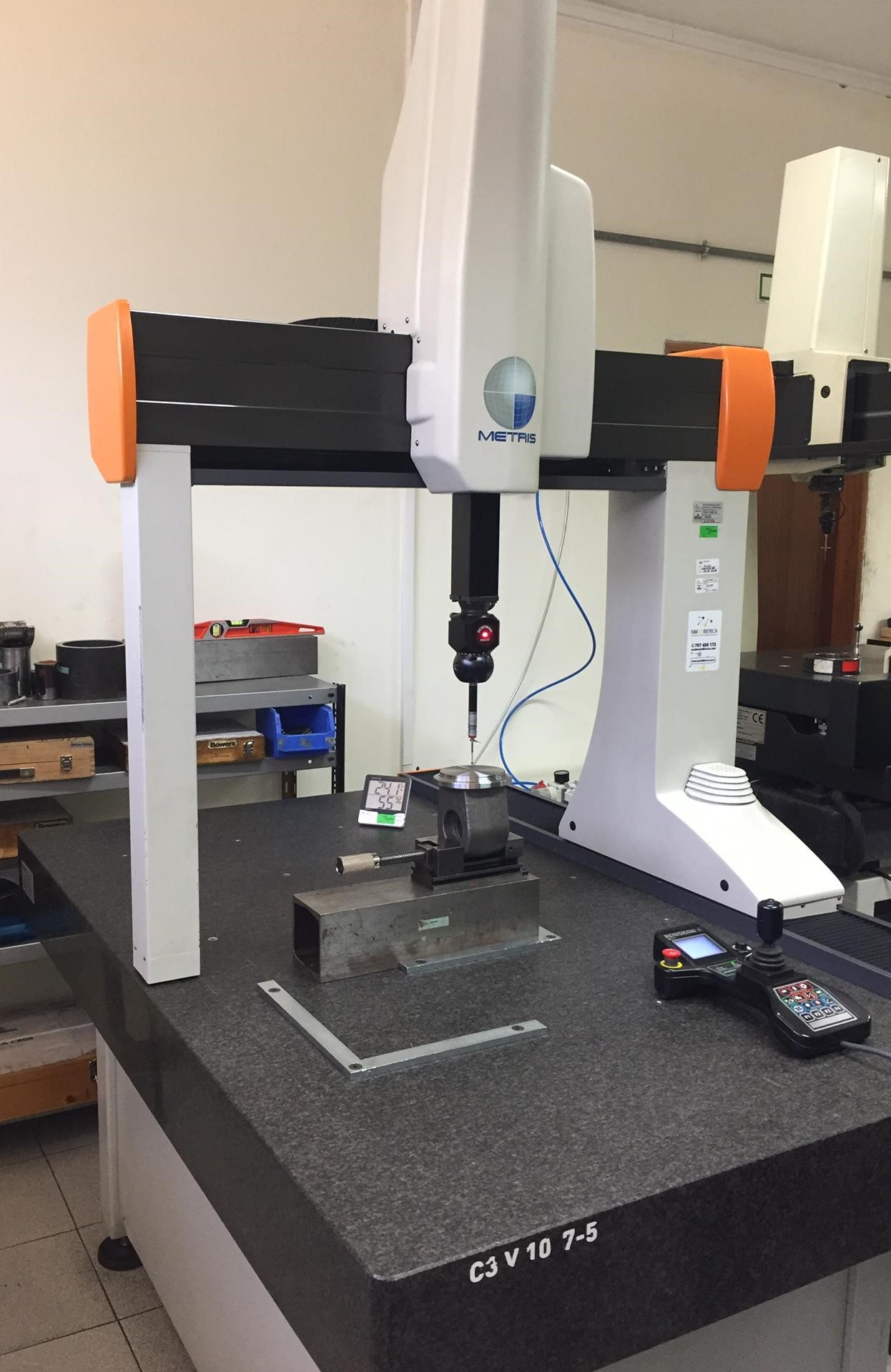

Certified by AENOR according to the standards ISO 9001:2015 and ISO14001:2015, Promecel has its main concern the customer satisfaction by the Quality of the supplied Service, with the minor possible impact to the environment.

To comply with all the quality requirements, Promecel has a rigorous Quality Management System as well as innovative control equipment that allows the continuous improvement of the processes.

Business

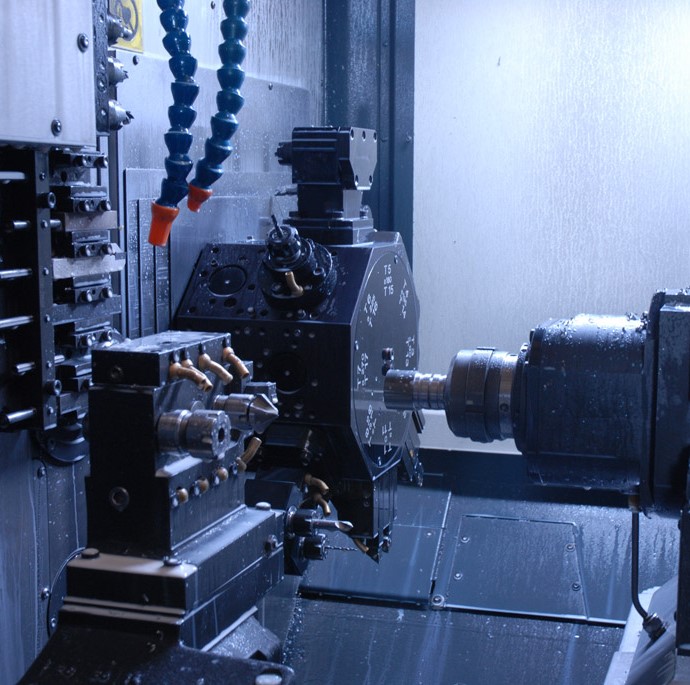

CNC Turning

CNC Milling

Aluminum Casting

Hot and Cold Stamping

Electroplating

Assembly Line

Industry Focus

Promecel is present is most of the industrial activity sectors, namely Agriculture, Hydraulics, Automobile Industry, Railways, Naval Industry, Shoe Manufacturing, Medicine, Hunting Weapons, Military, Aeronautical, Electrical, and others.

References

Optotech

Schenck Process

Leica

Inventron

Triumph Group

Manitowoc

Senvion

Silvadec

Sunviauto

Galland

ECCO

Delabie

Browning

Sahleduc

Balanças Marques

Products/Services/Offers

Products/Services

MACHINING

HIGH PRECISION COMPLEX MACHINED COMPONENTSWith more than 30 years of experience, Promecel has a wide range of CNC Equipment allowing the manufacturing of a wide array of pieces whose diameters may vary from 3mm to 650m and lengths up to 1100mm. Promecel has multiple precision milling and precision turning equipments which have from 2 to 10 axels. More ...

Foundry

FROM CONCEPTION TO THE FINISHED PIECEPromecel’s aluminum foundry sector has a great experience to produce components with the highest quality standards for the various industry sectors. More ...

Electroplating

SUPERIOR QUALITY SURFACE TREATMENTSThe Electroplating sector has automatic and manual production lines, capable of preforming superior quality surface treatments on the on a wide range of materials, from Brass to Steel, copper and stainless steel, etc. The available treatments are: Zinc-Acid with different passivations (without Chromium VI), Zinc Nickel, Tin Plating, Nickel Plating and phosphating.

Stamping

TURN-KEY PROJECTSThe stamping sector is equipped with mechanical presses, hydraulic presses, friction presses as well as hot stamping presses, from 30 TON to 150 TON, with automatic feeding equipment which are used to satisfy the specific production needs of its customers. More ...