Technoplast Group kft

Our company is at your disposal with almost forty years of professional experience in the field of plastic processing and metalworking. More than seventy of us work on providing complex services in plastic processing, tool-making and metalworking. Planning, engineering services, manufacturing by rapid prototyping, the production of tools, appliances, assembly jigs, non-series, small and large series plastic and metal parts and subassemblies and complex machines are among the activities of TECHNOPLAST GROUP Kft. as well as R&D activity.

Kontakt

Technoplast Group kft

Bódva u. 7.

H-3561 Felsőzsolca, Hungary

-

Show phone number

+36 46 379 308

- Show Email

- technoplast.hu

Contact Person

- Péter Halmos

-

Production Coordinator

-

Show phone number

+36 20 980 7732

- Show Email

Erika Szabó

Market Consulting

German-Hungarian Chamber of Industry and Commerce

H-1024 Budapest, Lövőház u. 30.

Tel: +36/1/3457-618

E-mail: szabo@ahkungarn.hu

www.duihk.hu

References

Profile

Galerie

Our Profile

Our company is at your disposal with almost forty years of professional experience in the field of plastic processing and metalworking. More than seventy of us work on providing complex services in plastic processing, tool-making and metalworking.

Planning, engineering services, manufacturing by rapid prototyping, the production of tools, appliances, assembly jigs, non-series, small and large series plastic and metal parts and subassemblies and complex machines are among the activities of TECHNOPLAST GROUP Kft. as well as R&D activity.

Our products are used in the machine industry, automotive industry, medical instruments manufacturing, electronics industry, aeronautical industry, space industry and other sectors requiring considerable development work. More than ninety per cent of our products are exported to Western European countries.

We believe that the secret of our success lies in keeping the quality of our products and services constantly at a high level and further improving them, therefore we operate in accordance with strict quality assurance standards – we provide detailed information on them on our site.

We trust that we can arouse your interest in the products and services of our company and we can welcome your company among our partners soon.

Business

Technologies

Design

We work with our own design team, if required, we also undertake the preparation of CAD / CAM plans and CNC programs

Engineering

We deal with product development, design of assembly units, devices for in-process and final inspection, coordination of inventions

Rapid prototyping

The essence of prototype manufacturing processes is that a part with the same geometry and similar material quality as the original product can be produced quickly and at low cost

Tool-making

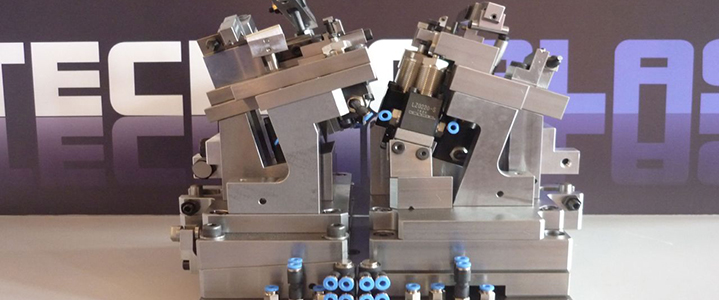

More than four decades of experience in the manufacture of plastic injection molding, rubber vulcanizing, countersinking and sheet metal forming tools

Devices and jigs manufacturing

For performing unique technical jobs we prepare assembly line devices and jigs for the automotive and electronics industry

Machining

Design and manufacture of general purpose parts with CNC and CAD / CAM technology in individual, small and large series

Plastic injection molding

Production of small and large series of plastic parts using various injection molding technologies

Painting, coating

We undertake the painting of plastic and metal parts in automotive quality

Plastic industry service

We offer complex solutions from product development to series production

--------------------------------------------------------------------------------------------------------

R+D+I activities

Our company is constantly engaged in research, development and innovation activities in its own projects, and we also support processes that meet the needs of customer, and result in the production of prototype products.

FOCUS project

Experimental Casting of Emulsion Foam at the International Space Station with a Foam Generator.

Client: ESA, European Space Agency

Customer: Admatis Kft., the designer of the device and the experiment.

The implementation was carried out by the member companies of the Hungarian Space Cluster. Components produced by Technoplast: box, window, casing, control buttons. The aim of the project was to study the foaming process and the stability of the foam in an emulsion system in a microgravity environment in order to lay the foundations for the development of the metal foam production technology.

The device was tested on 07/02/2010 at the ISS, International Space Station by the American astronaut Jeffrey Williams.

Production of prototype parts for the aviation and space industries

Justin, a humanoid robot, was developed by the German Aerospace Centre (DLR).

The main aim of creating Justin was to produce new space robots that could be mounted on satellites, maneuvered in space in various orbits, and controlled from Earth. They should be suitable for repairing other satellites.

Technoplast produced 23 vacuum-cast prototype parts for the project.

R&D&I&A, Research, Development and Innovation activities, and Industrial Applications (satellite parts, medical devices)

Weight reduction of aluminium alloy and titanium parts by reducing the wall thickness of the work pieces.

We participated in the DynaMill FP7EU project as a member of a ten-member international consortium led by Fraunhofer IPT in Aachen.

Project title: Dynamic manufacturing of thin-walled work pieces by milling process for the aviation, space and turbine industries.

The main aim of the project was to develop a complex CNC milling technology that includes FEM analysis, the development of cutting tools and cutting technologies, clamping devices that reduce vibrations, in order to achieve the best quality and the most efficient cost structure.

The results of the project are available to the member states of the European Union without any restrictions.

Development and production of shaped metal foam and plastic/rubber composite parts

An impact energy shock absorber for BMW made of an aluminium foam and plastic/rubber composite. (Exhibited at BMW Welt on 08/07/2014.)

In this case, a structure made of a combination of metallic and non-metallic materials is used. The core of the structure is made of metal foam by CNC cutting, pressing, forging or electrical discharge machining. The shell of the work piece is plastic or rubber.

Advantages of the parts:

- almost the same mechanical properties as those of the solid materials

- weight reduced by 60-70%

- good sound, vibration and energy absorbing capacity

- easy processing

Manual lamination of carbon fabric composites for producing STRINGBIKE bicycle parts

STRINGBIKE is a bicycle that uses a revolutionary new drive system instead of a traditional chain and sprockets, two special ropes attached to pulleys attached to swinging lever and cam mechanisms, a solution that ensures a more even load on the cyclist. This new design is fundamentally different from traditional drive systems and has a number of advantages. It is innovative and imaginative, both in terms of functionality and appearance.

Technoplast produced the carbon fabric composite frame and other handlebar parts.

Development of the production technology of shaped metal foam parts and the necessary equipment

The outer layer of a shaped aluminium part is a continuous thin shell. Its inner structure is a foam structure, as in human bones.

Advantages of the parts: almost the same mechanical properties as those of the solid materials, with a fraction of the weight thereof. Extremely varied shapes can be created. Potential areas of application: mechanical engineering, automotive industry, aviation industry, production of medical instruments, etc.

The R&D project was implemented within the framework of the Ányos Jedlik Program.

Supervisor: Admatis Kft.

Members: University of Miskolc, Department of Polymer Engineering, Bay Nano Technologies, Reform Kft., Technoplast Kft.

During the implementation of the project, we developed the production technology of shaped aluminium parts and the equipment necessary for production using the nanotechnological process and injection technology. The experiments were conducted in the metal foam laboratory of Technoplast. We conducted more than 3,500 experiments over four years.

The processes are protected by patents.

--------------------------------------------------------------------------------------------------------

Technoplast Medical Kft.

The predecessors of Technoplast Medical Kft. have been reliable suppliers of Hungarian, Swiss and German companies manufacturing medical instruments, medical devices, medical products, and pharmaceutical and cosmetic companies since 1985.

We have produced plastic injection moulded parts, packaging products and production tools in large series, millions of pieces per year for a Hungarian pharmaceutical company.

We have produced complete sets of packaging tools for tableting lines, additionally automated units and custom medical devices.

We have produced injection moulded products and production tools for Hungarian cosmetic companies.

In 2000, we started to use prototyping technologies, 3D printing, vacuum casting, RIM casting and small series injection moulding for producing custom and small series medical devices. Our products have been produced to order and exported to Western Europe.

We produce complete equipment, subassemblies, casings, various plastic and metal parts according to the needs of our customers. We produce custom, small series and large series pharmaceutical products. If required, we also participate in product development and prototype production. We produce complete, assembled lithotripters in series, the electronics of which are made by our German partner.

We produce large series of gynaecological devices assembled from injection moulded parts to orders from France, which will be exported to all over the world after obtaining the necessary permits and the CE marking. The quality of the products meets the MDR requirements for Class I devices.

Together with Hungarian universities, we participate in the development of new prototypes and series-produced medical devices.

To meet the growing demand for our products, on 1st September 2020 we established a separate, specialized company to perform these activities, Technoplast Medical Kft.

In order to meet the high requirements for our medical products, our company is in the process of introducing the ISO 13485 quality assurance system.

Industry Focus

Industries

Engineering

Our development group is specialized in solving unique technical tasks

We are engaged in product development, the development of assembly units, tools needed for work-in-progress and final inspection, the coordination of customer requirements, ideas and inventions, from design till implementation.

We have developed and are manufacturing cable harnesses for the cold and warm final inspection of motors for AUDI MOTOR HUNGÁRIA Kft. Their tailor-made shape and size allow different installation options even in difficult to access locations. Due to their high tolerance they can be applied under the most diverse working conditions.

Our individually designed cable harnesses are used by Audi Motor Factory and Allison Transmission gearbox factory for work-in-progress and final inspection of their products.

Machine industry

Design of machines and parts, machine building, production of plastic parts with 40 years of professional experience

Designing and producing components of general purpose, using CNC and CAD/CAM technology, in non-series, small and large series

Machining of steel, stainless steel, hardened steel, titanium, INVAR, hard metal, copper, brass, aluminium, aluminium alloy etc. materials by using 3-4-5-axle CNC milling machines, CNC lathes, sinker and wire electric discharge machines (EDM) as well as 3D measuring machines.

Manufacturing plastic components with 3D printing, rapid prototyping processes, injection moulding, (you can read more about them here). Assembling subassemblies from plastic and metal parts and manufacturing complex machines.

Automotive industry

Component production, tool making, device production from a number of pieces to a multi-million series size

- Parts manufacturing

Manufacturing of plastic and rubber interior and exterior parts as well as parts in the engine compartment, non-series and in small series, by applying rapid prototyping processes (3D printing, vacuum-casting, RIM casting); in medium series by injection moulding in plastic or Al-Bz inserts in soft tools; in large series with automatic hardened tools. If required we can paint the parts in accordance with the quality standards of the automotive industry.

Our goal is to satisfy customer requirements ranging from one piece to series of million pieces, applying the most efficient technologies (you can read more about them here).

Complete operating units are assembled from the parts. (E.g. passenger car A/C equipment).

- Tool-making, device manufacturing

Manufacturing of plastic injection moulding tools as a TIR1 and TIR2 supplier to German, Italian and domestic automotive enterprises (AUDI, VW, BMW, Aston Martin, Delphi, Bentley, Bosch, Shinwa).

Manufacturing of die forged tools and appliances for RÁBA Rt. since 1992. We are TIER2 level suppliers of GM, Meritor, Rockwell, Mercedes, Renault and ZF.

Manufacturing press dies and appliances used for assembly for the tool manufacturing plant of Audi, since 2008

Manufacture of medical instruments

We have been manufacturing medical instruments, medical devices and medical products for 35 years

We are reliable suppliers of domestic, Swiss and German companies manufacturing medical devices, medicinal products, pharmaceutical manufacturers and cosmetic firms since 1985. We prepare complete equipment, subassemblies, casings, various plastic and metal parts as required by our customers. We also produce unique, small and large series pharmaceutical products. If required, we participate in product development and prototype manufacturing. We mass-produce complete, assembled lithotripters for which the electronics are made by our German partner.

You can find more information about this activity on our website, Technoplast Medical Kft.

Aeronautical industry

We make tools, devices and measuring instruments for aerospace companies

- Tool making and machine building for aerospace companies

We are supplying tools, devices, GO/NOGO measuring instruments for machining, welding, soldering, assembling and inspecting gas turbines and other parts to French aeronautical companies for more than six years.

References: SAS Malichaud Atlantique France, Chromalloy France, Sarl Soudax Equipments France

Space industry

We make baffles, heat shields, brackets and shields for Sentimel 2 satellite types

- Manufacture of instruments and components for the aerospace industry

Regarding the space industry we produced baffles, heat protection elements, supports and heat shields for the different types of the Sentinel 2 satellites.

Within the frame of the FOCUS project of the European Space Agency we have manufactured the mechanical components of an experimental instrument. The instrument was tested on the International Space Station.

References

Video

Our company is at your disposal with almost forty years of professional experience in the field of plastic processing and metalworking. More than seventy of us work on providing complex services in plastic processing, tool-making and metalworking.

Planning, engineering services, manufacturing by rapid prototyping, the production of tools, appliances, assembly jigs, non-series, small and large series plastic and metal parts and subassemblies and complex machines are among the activities of TECHNOPLAST GROUP Kft. as well as R&D activity.