Strip's d.o.o.

Strip’s d.o.o. is your partner for the development and manufacturing of customer-specific electronic solutions, with expertise in the fields of lighting, household&professional appliances, automotive, medical, E-mobility, Smart energy, and IoT.

Kontakt

Strip's d.o.o.

Kandrše 7

1252 Vače, Slovenia

-

Show phone number

+386 3 567 07 70

- Show Email

- www.strips.eu

References

Certifications

Our comprehensive quality management concept is based on the globally recognized ISO 9001: 2015 standard and is complemented by ISO 14001: 2015 and ISO 50001: 2011.

CERTIFICATES: ISO 9001:2015, ISO 14001:2015, DIN EN ISO 50001:2011

CERTIFICATIONS: VDE, UL, TÜV, ENEC, CE, EMC

METHODS: APQP, PPAP, LEAN, TQM

Profile

Galerie

COMPANY

Strip’s focuses on development and manufacturing of customer-specific electronic solutions since 1995. Our expertise in the fields of Lighting, Household & Professional Appliances, Automotive, Medical, E-mobility, Smart Energy and IoT makes us reliable and flexible EMS and ODM partner. Broad spectrum of technical expertise, engineering experience and production capabilities give us freedom in the creation of products, services and solutions. From concept design, prototyping, industrialization to serial production, quality assurance and logistics support, we cover the entire service chain and help you turn your idea into a product, ready for market.

WHY US

- Personal approach and full customer service, no matter the size or complexity of the project

- Broad technical and engineering expertise in electronics, software development, mechanical and optical design

- Broad production capabilities, ranging from simple electronic modules to full product assemblies

- Well-established, diverse and global supply chain

- Cost efficiency and high degree of flexibility and agility

- Convenient geographical position, easily accessible from everywhere in Europe

- Long term partnerships, built on the foundation of reliability and quality

Business

PRODUCT DEVELOPMENT

Creating a product that will set you apart from your competitors is challenging. Extensive expertise and many years of experience enable us to design, develop and manufacture products with high added value while guaranteeing consistent high quality and an excellent price-performance ratio.

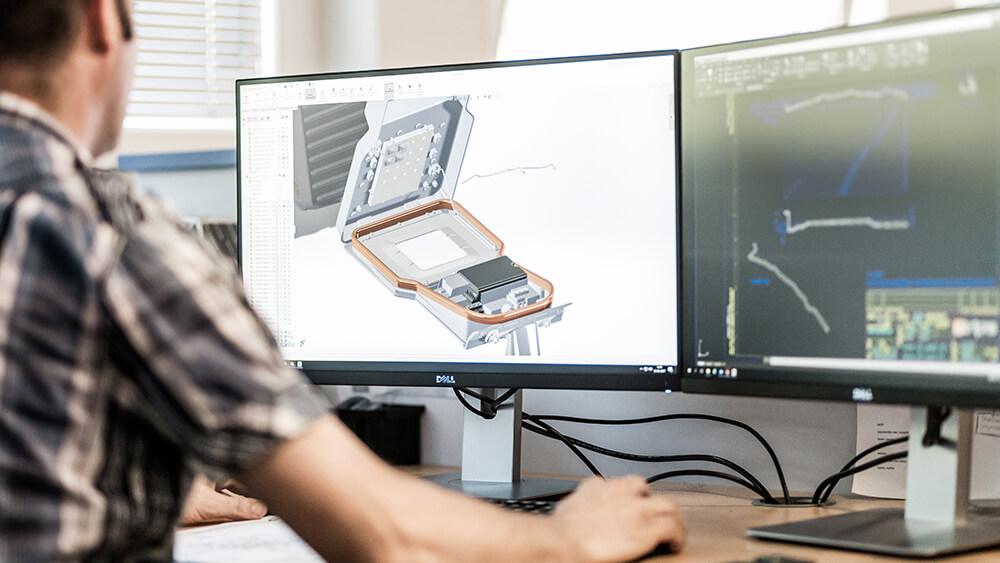

CONCEPT DESIGN

Understanding the needs of a customer and reflect them in the final product is essential. During concept design we define product performance, while also tune and customise it across various customer needs. Next step that we take is to define the best product architecture, recognise and mitigate risks, control cost, features and time to market.

Benefits: Reliable & cost-effective product that fully meets customer’s requirements

DEVELOPMENT

During development we will work closely with you, guide you through the complete development process, and once your product is developed, we will produce it in our factory.

Product development consists of technical specification and requirements definition, architecture definition, BOM optimization, HW, SW and mechanical designs, electric and thermal simulations, optics simulation and design, functional tests, end of line test equipment design, highly accelerated lifetime tests and packaging design. Design processes follow known project management standards.

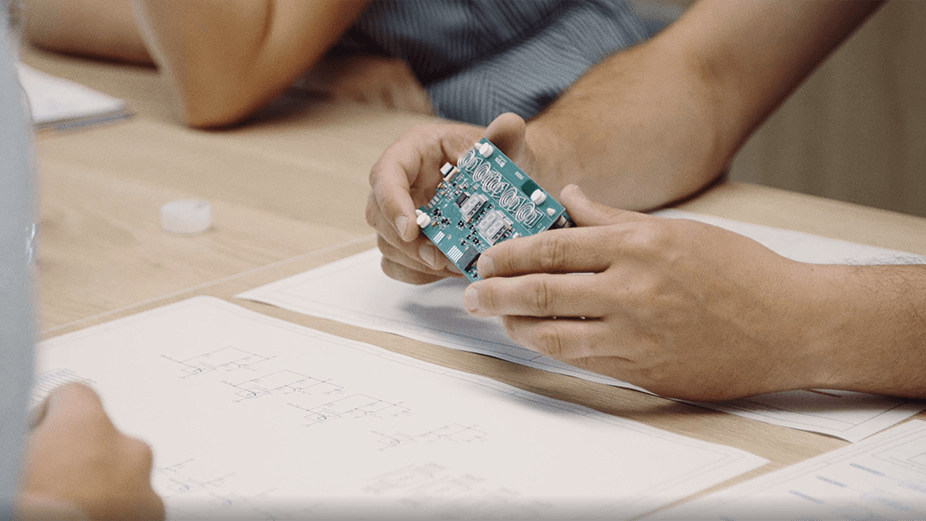

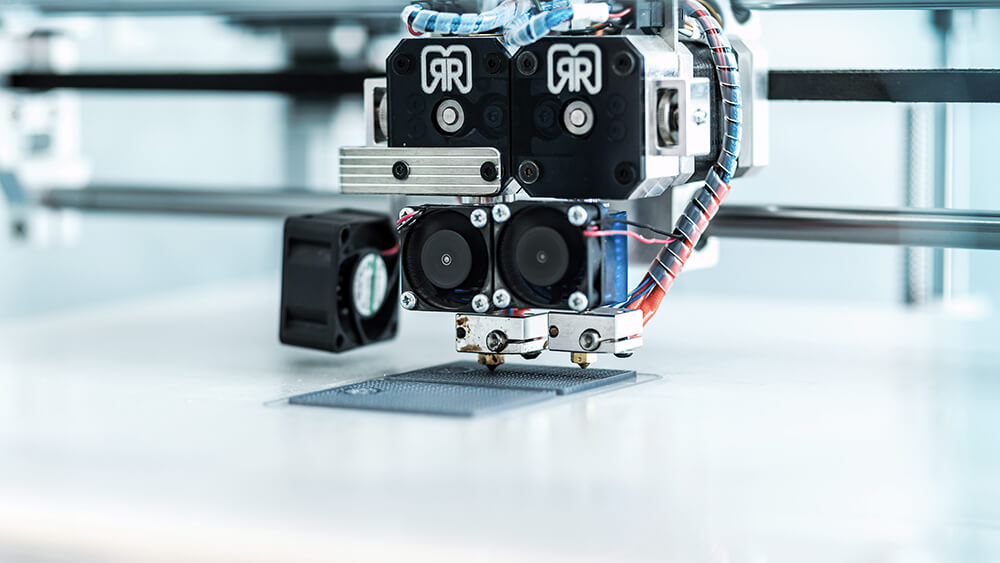

PROTOTYPING

With prototyping or low volume assembly we offer you full service of manual or automated PCBA assembly, including 3D prints and support assembly parts. Prototypes allow you to test a form and functions, present them to your customer or stakeholders, ensuring they have been designed appropriately for manufacturing.

INDUSTRIALIZATION

Strip’s is design for manufacturing oriented. With the experience in APQP/PPAP all projects are coordinated with standardized reviews and the predictable project flow. Tools such as DFMEA enable us to analyse manufacturability in early stage of development and consequently reduce product costs.

If required, we will take full care of individual product certification. This is taken into consideration already during the development phase, which leads to quicker and easier product certification process.

As EMS provider Strip’s is using broad set of test methods and test equipment and we have knowledge and experience for consistently ensuring high quality levels.

ELECTRONICS MANUFACTURING SERVICES

For companies of all sizes and industries, our team of manufacturing experts has the branch-specific skills and knowledge to offer comprehensive service for your electronic products and to deliver value throughout the entire product development, launch, and post-launch support process.

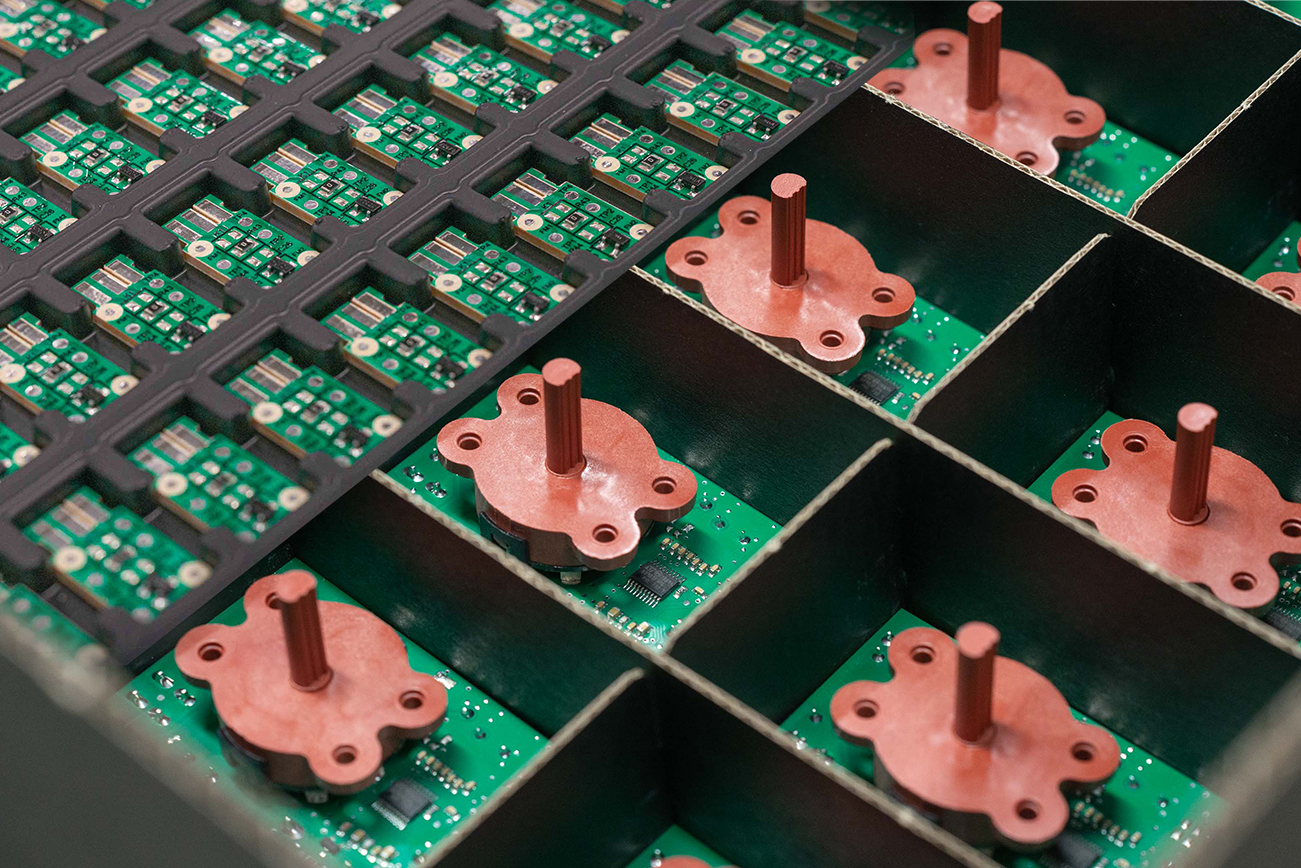

PRODUCTION

We are very flexible with our PCBA process and are able to provide you with customized solutions for your system, including supporting any special requirements when needed, such as stress-free de-panelling. Our PCBA contains all the necessary technologies such as surface mount technology (SMT), laser marking, through hole technology (THT), cleaning, coating, programming, rework and repair, to provide you custom made solution for your system.

Based on experience, we choose the most appropriate test method in terms of quantity and cost. Test methods used in production:

- SPI (Solder Paste Inspection)

- AOI (Automated Optical Inspection)

- ICT (In Circuit Test)

- FCT (Function Test)

- Burn-in

We ensure full traceability and have been successfully optimizing our material flows and processes using LEAN methods for several years now.

QUALITY ASSURANCE

Our highest priority and responsibility are to provide first-class products with the highest level of quality to our customers and meeting their expectations. To achieve this goal, we include carefully selected quality methods in all our processes to all development stages, production, sales and after-sales activities.

We always listen to our customers and other stakeholders, and take the time to understand their requests, desires and expectations. In our search of finding the best solution we systematically engage our middle management and all employees in finding the best solutions. We have established a good foundation and a reward system for promoting new ideas, initiatives and innovations. The responses of recognizable, renowned domestic and foreign customers after each assessment prove that our procedures are adequately structured, planned and implemented.

Our comprehensive quality management concept is based on the ISO 9001: 2015 standards which are recognized worldwide and supplemented by ISO 14001: 201

5 and ISO 50001: 2011.

CERTIFICATES: ISO 9001:2015, ISO 14001:2015, DIN EN ISO 50001:2011

CERTIFICATIONS: VDE, UL, TUV, ENEC, CE, EMC

METHODS: APQP, PPAP, LEAN, TQM

LOGISTICS SUPPORT

The electronic boards are packed in customised packaging to meet the maximum protection and customer requirements. We provide worldwide deliveries by land or sea by professional carriers with economic competitiveness. To meet our goals, just-in-time delivery and customers continuity of supplies, Strip’s is offering buffer stock with which we can eliminate order peaks and other unpredictable circumstances.

DEVELOPING AN INTEGRATED SMART SOLUTIONS FOR COMMUNITY

Having a highly skilled development department allows us to develop innovative solutions and effectively and uniquely integrate them into smart city projects.

References

Video

Products/Services/Offers

Products/Services

PRODUCT DEVELOPMENT

PRODUCT DEVELOPMENTCreating a product that will set you apart from your competitors is challenging. Extensive expertise and many years of experience enable us to design, develop and manufacture products with high added value while guaranteeing consistent high quality and an excellent price-performance ratio. CONCEPT DESIGNUnderstanding the needs of a customer and reflect them in the final product is essential. During concept design we define product performance, while also tune and customise it across various customer needs. Next step that we take is to define the best product architecture, recognise and mitigate risks, control cost, features and time to market. Benefits: Reliable & cost-effective product that fully meets customer’s requirements DEVELOPMENTDuring development we will work closely with you, guide you through the complete development process, and once your product is developed, we will produce it in our factory. Product development consists of technical specification and requirements definition, architecture definition, BOM optimization, HW, SW and mechanical designs, electric and thermal simulations, optics simulation and design, functional tests, end of line test equipment design, highly accelerated lifetime tests and packaging design. Design processes follow known project management standards. Benefits: Turning your idea into a product Cooperation in product design, project milestones and product documentation Full product service support Reduce product costs Serial production Enhance and optimize manufacturing processes Improve product quality and reliability Speed up time to market Enhance user experience and increase customer satisfaction PROTOTYPINGWith prototyping or low volume assembly we offer you full service of manual or automated PCBA assembly, including 3D prints and support assembly parts. Prototypes allow you to test a form and functions, present them to your customer or stakeholders, ensuring they have been designed appropriately for manufacturing. Benefits: Test all properties, electrical, mechanical, functional and user experience before serial production Present product to customer Improve production processes Check market and get feedback before serial production INDUSTRIALIZATION Strip’s is design for manufacturing oriented. With the experience in APQP/PPAP all projects are coordinated with standardized reviews and the predictable project flow. Tools such as DFMEA enable us to analyse manufacturability in early stage of development and consequently reduce product costs.If required, we will take full care of individual product certification. This is taken into consideration already during the development phase, which leads to quicker and easier product certification process. As EMS provider Strip’s is using broad set of test methods and test equipment and we have knowledge and experience for consistently ensuring high quality levels. Benefits: Reduced time to market Reduced costs Robust product Design for test

Offers

Strip's d.o.o. - ELECTRONICS MANUFACTURING SERVICES

ELECTRONICS MANUFACTURING SERVICES For companies of all sizes and industries, our team of manufacturing experts has the branch-specific skills and knowledge to offer comprehensive service for your electronic products and to deliver value throughout the entire product development, launch, and post-launch support process. PRODUCTION We are very flexible with our PCBA process and are able to provide you with customized solutions for your system, including supporting any special requirements when needed, such as stress-free de-panelling. Our PCBA contains all the necessary technologies such as surface mount technology (SMT), laser marking, through hole technology (THT), cleaning, coating, programming, rework and repair, to provide you custom made solution for your system. Based on experience, we choose the most appropriate test method in terms of quantity and cost. Test methods used in production: SPI (Solder Paste Inspection) AOI (Automated Optical Inspection) ICT (In Circuit Test) FCT (Function Test) Burn-in We ensure full traceability and have been successfully optimizing our material flows and processes using LEAN methods for several years now. Benefits: Broad set of production capabilities Ability to adapt to individual customer requirements Box build assembly Quality Full traceability Flexibility QUALITY ASSURANCE Our highest priority and responsibility are to provide first-class products with the highest level of quality to our customers and meeting their expectations. To achieve this goal, we include carefully selected quality methods in all our processes to all development stages, production, sales and after-sales activities. We always listen to our customers and other stakeholders, and take the time to understand their requests, desires and expectations. In our search of finding the best solution we systematically engage our middle management and all employees in finding the best solutions. We have established a good foundation and a reward system for promoting new ideas, initiatives and innovations. The responses of recognizable, renowned domestic and foreign customers after each assessment prove that our procedures are adequately structured, planned and implemented. Our comprehensive quality management concept is based on the ISO 9001: 2015 standards which are recognized worldwide and supplemented by ISO 14001: 2015 and ISO 50001: 2011. CERTIFICATES ISO 9001:2015 ISO 14001:2015 DIN EN ISO 50001:2011 CERTIFICATIONSVDE, UL, TUV, ENEC, CE, EMC METHODSAPQP, PPAP, LEAN, TQM LOGISTICS SUPPORT The electronic boards are packed in customised packaging to meet the maximum protection and customer requirements. We provide worldwide deliveries by land or sea by professional carriers with economic competitiveness. To meet our goals, just-in-time delivery and customers continuity of supplies, Strip’s is offering buffer stock with which we can eliminate order peaks and other unpredictable circumstances. Benefits: Returnable packaging – sustainable practice Custom made packaging – perfect fit Flexibility