HSTEC d.d.

HSTec is an innovative development and production company with many years of experience in the field of high-speed motorized spindles, industrial automation and robotics.

Kontakt

HSTEC d.d.

Zagrebačka 100,

HR-23000 Zadar, Croatia Zadar, Croatia

-

Show phone number

+385 23 205 405

- Show Email

- www.hstec.hr

Contact Person

- Ivan Mokos

-

Show phone number

+385 23 205-414

- Show Email

Melita Maganić

Member Relations & Start-ups

AHK Croatia

Phone: +385 1 6311 611

[email protected]

www.kroatien.ahk.de

Profile

Galerie

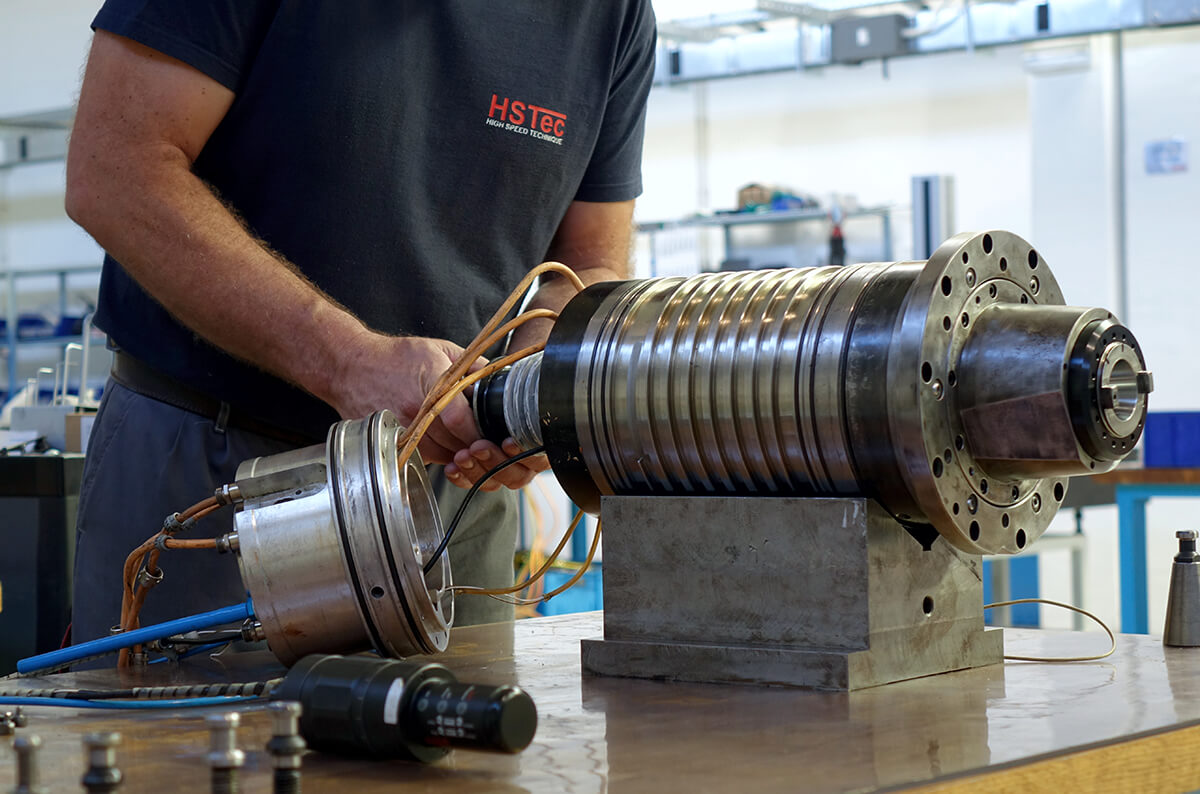

HSTec is an innovative development and production company with many years of experience in the field of high-speed motorized spindles, industrial automation and robotics.

The concept of product development is based on the principles of open innovation and special prototype production. Of great importance are the continuous improvement and adoption of new technologies and the collaboration with scientific research institutions.

The founding of the company in 1997 was realized in cooperation with the German company Bosch-Rexroth (formerly INDRAMAT), a world renowned company in the production of electric motor drives and the company SAS Zadar, known for the production of special machine tools and systems.

HSTec offers a wide range of customized motorized spindles, direct driven units, special machine tools and assembly machines, as well as the implementation of robotic cells for various applications.

A flexible team of leading mechanical and electrical engineers continually launches new product development and offers creative and comprehensive solutions in the field of industrial automation.

In addition to the core business activities, development and manufacturing of innovative products, HSTec has become the regional market leader in service, repairs and optimization of motorized spindles.

HSTec especially emphasizes its orientation to the needs and satisfaction of its customers, the introduction of new technologies and the achievement of the highest standard of professionalism in project performance and documentation, and the expansion to the new markets and the creation of new products and services. The company applies and continually improves the efficiency of a quality management system in accordance with the requirements of the international standard ISO 9001: 2015. The quality of the managerial activities, the more efficient connectivity between the departments, as well as the business process control are all achieved through the ERP-PLM business information system.

The long-term vision is to contribute to the development of the new concept - Industry 4.0 on a global scale, which aims to create smart products and factories by integrating ICT technology and digitizing different sensor systems as a path to improving the quality and efficiency of production processes.

HSTec exports around 75% of its products and services to demanding world markets, mostly within the European Union. Among the references we emphasize: KADIA Produktion, BOSCH REXROTH Group, KOLB Design Technology, ELB-SCHLIFF Wekzeugmaschinen, Schwäbische Werkzeugmaschinen, MAUSER-WERKE, HAINBUCH, OMCO Group, SCHAEFFLER Technologies, DITTEL MARPOSS Group, MWA Werkzeugmaschinen, SEMA Maschinenbau, LERINC Werkzeugmaschinen, SAV, NOVEM Car Interior Design, Hellmerich Precision Components, Dynomax, Mollart, UNIOR.

HSTec represents globally renowned companies in automation and drive technology:

Balluff – sensors / systems for linear displacement measurement, identification, object detection

Hofmann – balancing machines and vibration technology

Rexroth Bosch – electric drives and controls

Alpha Wittenstein – servo drive systems and planetary gearboxes

Mitutoyo – precision measuring instruments

Business

HSTec's development team of mechanical and electrical engineers offers custom made solutions, advises the customer, improves and automates existing manufacturing processes in various industries.

Our strengths are our expertise and know-how and we are proud to be a part of the new concept of developing intelligent and networked systems by creating smart products. Integration of sensor technology, ICT technology, electronic data logging and vision systems into our products gives us the benefit of developing highly technological and innovative drive systems, custom made assembly machines, machine tools and robotic cells.

- HSM High-speed motorized spindles

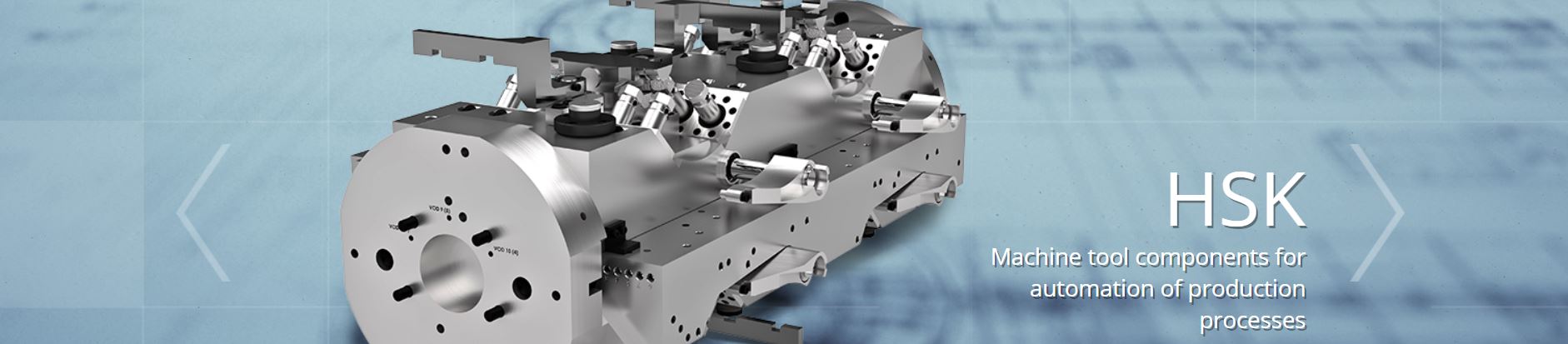

- HSK Machine tool components

- HSW Special machines and devices

- HSR Robotic automation

Spindle service and repairs

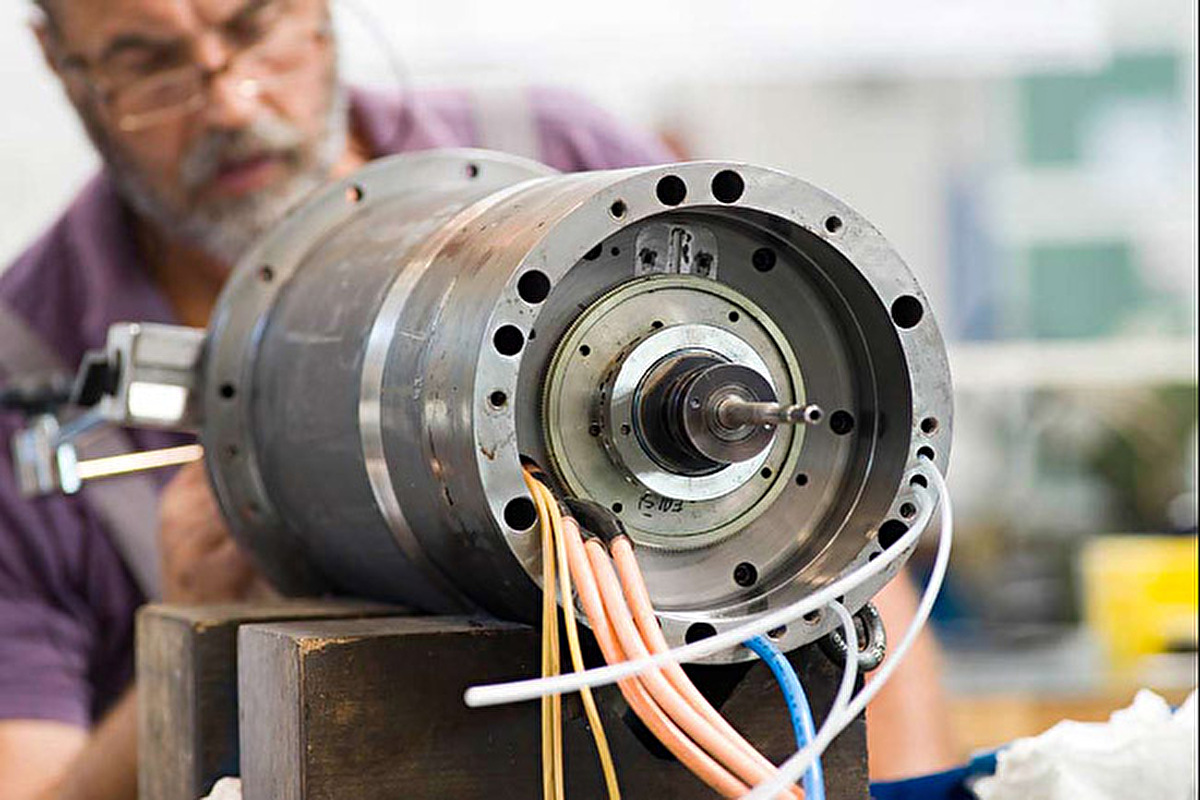

HSTec offers service, repairs, redesign and optimization of spindles and motorized spindles of all global manufacturers. Based on years of experience in development and production of innovative high-speed motorized spindles we became leading experts for repairs and optimization of motorized spindles, belt-driven and direct-driven spindles for various applications: grinding, milling, turning, boring.

Our department for spindle service and repairs is equipped with a modern welding device for repairing damaged parts, numerous CNC machine tools, lathes and highly precise grinding machines.

Various test and diagnostic equipment is used, namely spindle vibration analysis equipment - Hofmann and SKF, high-voltage insulation testing of stator windings - Baker, testing equipment of accuracy and precision of various sensor types such as high resolution motor speed and position sensor and incremental and absolute encoders (Heidenhain, Lenord Bauer, VS-Senzorik, Siemens).

We offer complete refurbishment of damaged spindle parts such as HSK and SK cones, bearings and more.

Production

HSTEC offers small batch production of high precision custom machined parts.

Our production department consists of high-precision four- and five-axis machining centers, CNC lathes, cylindrical and planar grinding machines, and coordinate measuring machines. For prototyp part production the newest laser welding device and 3D printing machine are used.

New technologies, air-conditioned spaces and controlled working conditions provide high-precision manufacturing and superior product quality.

Assembly and product testing

Our product assembly and product testing department uses high-tech testing devices and equipment, balancing test stations, high-frequency regulators, and various dedicated test stations.

Downloads

Video

Products/Services/Offers

Products/Services

Development and design of high-speed drives and robotic automation

Development and design of high-speed drives and robotic automation HSTec's development team of mechanical and electrical engineers offers custom made solutions, advises the customer, improves and automates existing manufacturing processes in various industries. Our strengths are our expertise and know-how and we are proud to be a part of the new concept of developing intelligent and networked systems by creating smart products. Integration of sensor technology, ICT technology, electronic data logging and vision systems into our products gives us the benefit of developing highly technological and innovative drive systems, custom made assembly machines, machine tools and robotic cells.

High-speed motorized spindles

High-speed motorized spindles HSTec offers customized solutions as well as special design of motorized spindles. According to our customers’ needs, the following can be specified: spindle dimensions, spindle torque, motor speed, tool clamping, tool interface, bearing, lubrication type and position sensor type. Special direct driven units represent a subgroup of our HSM product line. Designed for optimum performance and custom made for special applications. This subgroup has numerous design features and drive types such as: linear drive units, two-axis milling heads with integrated high-speed motorized spindle, built-in high torque motors with integrated load cells, direct driven turntables and other.

Offers

HSTEC d.d. - Repairs of main spindles, motorized spindles and electrical motors (1)

Spindle service and repairs HSTec offers service, repairs, redesign and optimization of spindles and motorized spindles of all global manufacturers. Based on years of experience in development and production of innovative high-speed motorized spindles we became leading experts for repairs and optimization of motorized spindles, belt-driven and direct-driven spindles for various applications: grinding, milling, turning, boring. Our department for spindle service and repairs is equipped with a modern welding device for repairing damaged parts, numerous CNC machine tools, lathes and highly precise grinding machines. Various test and diagnostic equipment is used, namely spindle vibration analysis equipment - Hofmann and SKF, high-voltage insulation testing of stator windings - Baker, testing equipment of accuracy and precision of various sensor types such as high resolution motor speed and position sensor and incremental and absolute encoders (Heidenhain, Lenord Bauer, VS-Senzorik, Siemens). We offer complete refurbishment of damaged spindle parts such as HSK and SK cones, bearings and more.

HSTEC d.d. - Small batch production of high precision machine parts

Small batch production of high precision machine parts HSTEC offers small batch production of high precision custom machined parts. Our production department consists of high-precision four- and five-axis machining centers, CNC lathes, cylindrical and planar grinding machines, and coordinate measuring machines. For prototyp part production the newest laser welding device and 3D printing machine are used.New technologies, air-conditioned spaces and controlled working conditions provide high-precision manufacturing and superior product quality. Assembly and product testingOur product assembly and product testing department uses high-tech testing devices and equipment, balancing test stations, high-frequency regulators, and various dedicated test stations.

Catalogs/Brochures

HSTEC d.d. Products and services - High-speed motorized spindles, industrial automation and robotics.