Ferpol Kft.

FERPOL founded in 2004 as a family company. Main profile is manufacturing plastic PVC connecting elements for concrete manholes in our production plant at Miskolc. Through long term market experience, expertise, as well as reliability FERPOL has developed itself into a wellknown plastic product supplier for Multinationel Partners. Our activities: production of PVC plastic channel profiles, PVC injection molding, production of floor leveling systems milling, turning, surface grinder, heat treatment, custom manufacture, series production, purchase of raw materials, storage, chopping.

Kontakt

Ferpol Kft.

Miskolc Erdő sor 26/a

H-3518 Cím, Hungary

-

Show phone number

+36 30 451-03-92

- Show Email

- ferpol.hu

Contact Person

- SIMON Richárd

-

Managing Director

-

Show phone number

+36 30 4510392

- Show Email

Ilona Balogh

Deputy Managing Director, Head of Market Consulting Division

German-Hungarian Chamber of Industry and Commerce

Tel: +36/1/3457-631

E-mail: [email protected]

www.duihk.hu

VAT number

HU13274984205Certifications

CERTIFICATES AND QUALITY MANAGEMENT

We have adapted our integrated management system to the MSZ EN ISO 9001: 2015 and MSZ EN ISO 14001: 2015 standards. The regulations must be applied by all employees of the company.

- ISO 9001 STANDARD

- ISO 14001 STANDARD

- NATIONAL TECHNICAL APPROVAL A-145/2015 (NMÉ)

Profile

Galerie

FERPOL founded in 2004 as a family company. Main profile is manufacturing plastic PVC connecting elements for concrete manholes in Our production plant at Miskolc.

Through long term market experience, expertise, as well as reliability FERPOL has developed itself into a wellknown plastic product supplier for Multinationel Partners.

The COMPANY offers

- Plannable costs for longterm relationships

- High quality and durability with NMÉ Quality Certificates

- Decreasing delivery time, assisted by 2 months stock for flexibility

- Environment protection with recycled raw materials

PRODUCTION HALL

In 2015, we proudly opened our new production hall paralell with the new technology, that increase reliability and quality of our great products. The new 320t clamp force injection mould machine increase the volume with efficient energy consumption.

Our warehouses provide an opportunity to respond flexibly to customer needs. We typically have a 2 month product stock.

OUR SERVICES

- Raw material distribution

- Joint R&D

- Mass production

- Injection molding

- Tool storage

- Finished product packaging

- Logistics solutions

Business

PRODUCTS

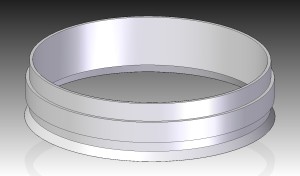

Beside the traditional KGFP connecting elements FERPOL makes prdoucts with defined customer requirements to fit into concrete manholes/shafts across Hungary and Romania.We deliver our products with BODE rubber sealing (Germany) for best quality.

Our masonry profiles are made according to individual customer requirements, in a reinforced design on the outer mantle. Quartz sand is applied to the outer surface of our products for perfect waterproofing. Our products are delivered exclusively with German quality BODE lip rubber ring. We also produce extra watertight masonry for thin manholes.

KDU EXTRA SHAFT CONNECTOR

The shaft joint, as it does not have a rubber ring housing, is made in a mantle-reinforced strapped design to improve static rigidity. This makes it perfectly resistant to deformation forces during installation.

D (internal)

268.9 mm

330.7 mm

427.0 mm

542.5 mm

WE ARE ALSO AVAILABLE IN THE MANUFACTURE OF UNIQUE PRODUCTS!

KGFP SHAFT CONNECTOR

In addition to the long (L = 240mm) masonry profiles available in retail and wholesale trade, our company also manufactures masonry profiles that can be inserted into shaft rings specifically for large concrete prefabrication companies on the basis of a manufacturer's order.

It can be straight-walled, curved for installation in D450, D1000 or D1450 shaft rings.

PLASTICPROCESSING TECHNOLOGIES

Our family company in the past 10 years focused the resources to be better at polimer processing technologies. We work as a strategic supplier for multinational companys. Our newly developped products are created in the new production hall (2015) with injection mould machines. The company can handle 3 shifts work schedule according to increased cutomer needs.

We are also prepared to make injection mould plastic parts for new customers until 320 tonnes clamp force and 1000 cm3 swept volume in the production plant at Miskolc

GRANULE TYPES

LDPE, HDPE, PP, PA, PS, ABS, TPE, PC, PVC, TPU

Downloads

Products/Services/Offers

Offers

Ferpol Kft - PLASTICS PROCESSING TECHNOLOGIES

PLASTICS PROCESSING TECHNOLOGIESOur family business has focused resources over the last 10 years to become better in plastics processing technologies. We work as a strategic supplier for multinational companies. Our newly developed products are manufactured in the new production hall (2015) with injection molding machines. The company can work in 3 shifts according to the increased demand of customers. We are also ready to produce injection molded plastic parts for new customers up to 320 tons clamping force and 1000 cm3 displacement in the production facility in Miskolc.