Fundiciones Julcar S.L.

Certified ISO 9001, IATF 16949 & ISO14001, JULCAR, created in 1981 in Burgos (Spain), is nowadays a leading manufacturer of Aluminum and Zamak High Pressure Die Castings.

Kontakt

Fundiciones Julcar S.L.

Polígono Industrial Villalonquejar Calle Valle de Mena, 21

09001 Burgos, Spain

-

Show phone number

+34 947 29 80 87

- Show Email

- julcar.com

Contact Person

- Sylvie BASTOS

-

Export Commercial

-

Show phone number

+34 610 204 494

- Show Email

Camino LEON

Commercial assistant

Phone: (+34) 616 498 067

[email protected]

Profile

Galerie

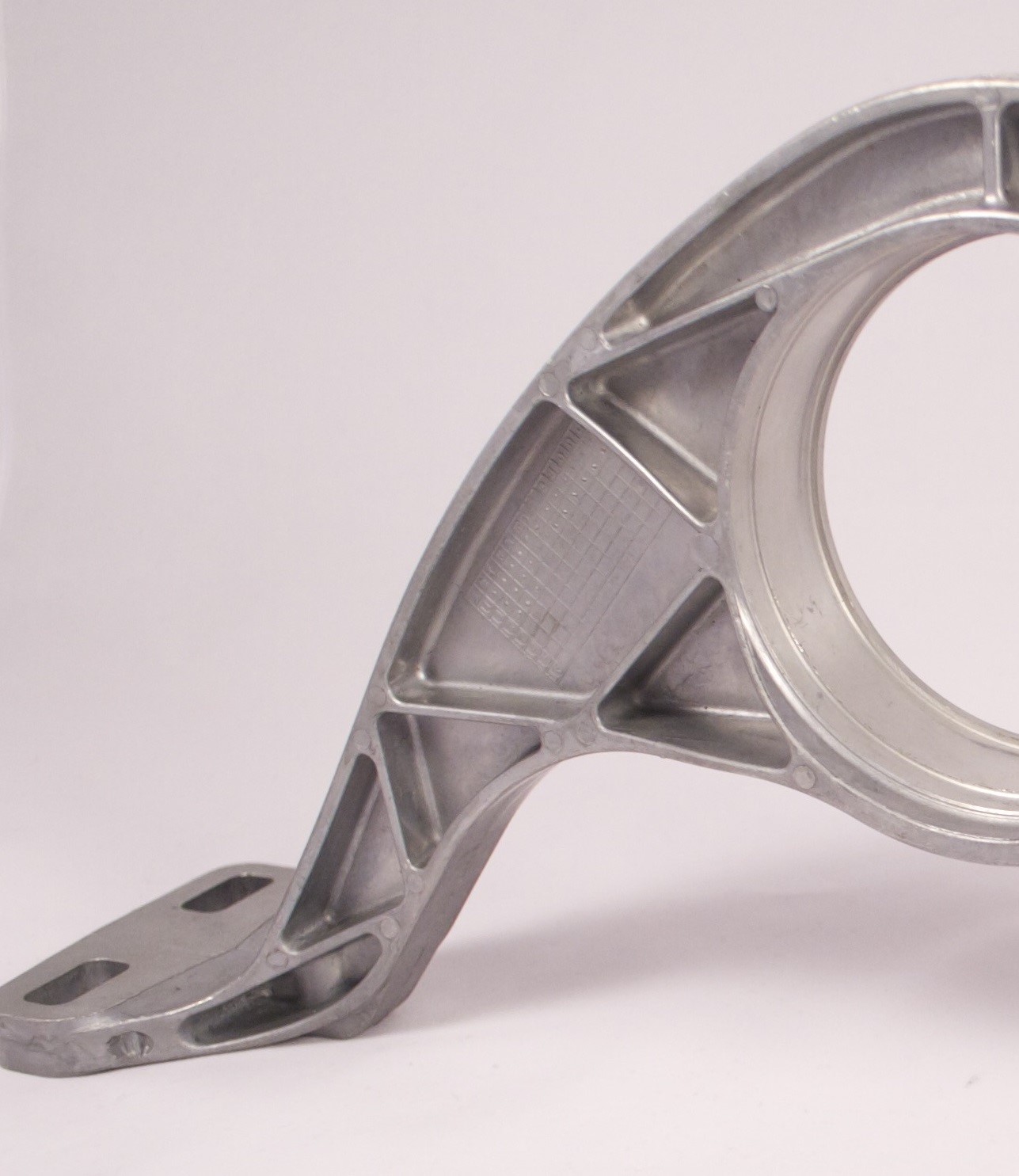

ALUMINIUM AND ZAMAK HIGH PRESSURE DIE-CASTING

Certified ISO 9001, IATF 16949 & ISO14001, JULCAR, created in 1981 in Burgos (Spain), is nowadays a leading manufacturer of Aluminum and Zamak High Pressure Die Castings:

- 8 aluminum machines from 125T to 1250T

- 3 zamak machines from 80T to 220T

- Making parts from 10g to 2.5kg

- Series from 30,000 up to 800,000 per year (depending part size)

- And specialized in the automotive industry (85%)

With the extensive experience acquired over the years and the continuous investments made, our commitment is always to guarantee our customers the best quality for their parts at very competitive prices, delivery terms and deadlines.

Our strengths:

- Our qualified and committed human team

- Our know-how

- Our flexibility

- Our pro-activity

To guarantee that our processes carried out comply with the requirements of our customers, our quality department has the following main quality means:

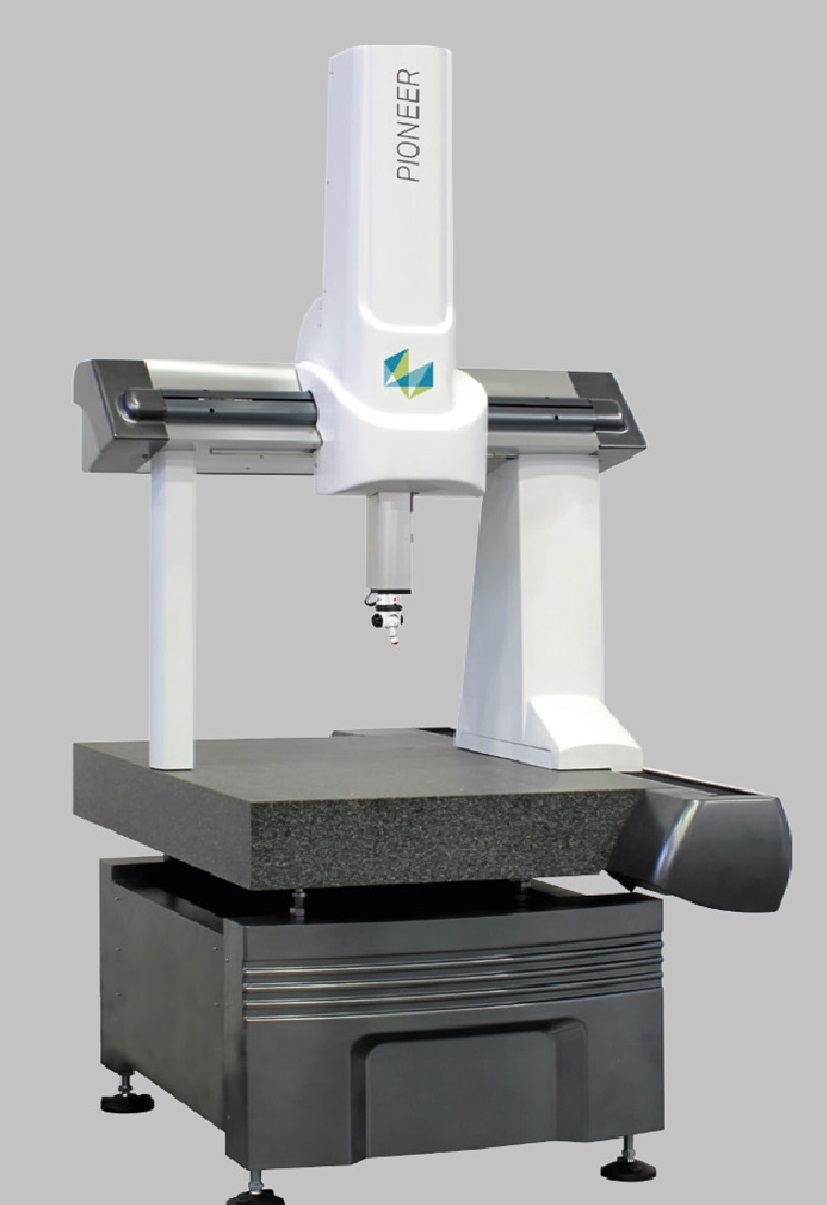

- 3D machine

- Spectrometer

- X ray machine

- Traction-breaking machine

- Dynamometer

- Roughness tester

- Thickness gauge

- Profile projector

- Poka-yoke

- Control gauges

- And other conventional measuring instruments: Go-No Go, Calipers, etc

We also work with approved external laboratories to carry out specific tests.

Business

Our main objective is the total satisfaction of our customers . Therefore, we provide a comprehensive response to their needs:

- MOLD FLOW SIMULATION

- TECHNICAL SUPPORT

- TOOLS MANUFACTURING:

- Molds

- Trimming cuts

- INJECTION ALUMINUM AND ZAMAK HIGH PRESSURE DIE CASTINGS

- SURFACE FINISHING:

- Vibrating

- Shot blasting

- MACHINING

- ASSEMBLY

- SURFACE TREATMENT:

- Painting

- Cataphoresis

- Chrome plating

- Zinc plating, etc.

We also provide our customers with prototype parts by manufacturing prototype mold or by managing them with specialized companies.

In the offer phase, JULCAR likes to recommend to our clients the possible improvements, changes, or suggestions so that the manufacture of the part is more optimal.

In case JULCAR has been nominated for the manufacture of a part, we would go into much more detail establishing a close collaboration between the technical / engineering departments of both companies.

Due to the experience acquired over the years in high pressure die casting, the recommendations we offer to our clients are generally necessary to minimize problems during the injection process, facilitate the proper filling of the part and therefore improve its injection quality.

JULCAR is always offering an optimal service at any time from the development of the part to its serial production.

Our commitment to our clients is always to guarantee high quality standards with competitive prices, delivery terms and deadlines.

So, in case you do need any aluminum and / or zamak die castings, we will be pleased to receive any inquiry from your side.

Kind regards,

JULCAR TEAM

Industry Focus

- Automotive (85%)

- Windows and Doors Harwares (10%)

- Others (5%)

Downloads

Products/Services/Offers

Offers

Fundiciones Julcar S.L. - What can we do for you

What can we do for you SET DESIGN SIMULATION OF FILLING Toolmaking CASTING DIES FINISHES SURFACE FINISHING DECORATIVE MACHINING QUALITY CONTROL PACKAGING EXPEDITION VALUES THAT JULCAR CAN CONTRIBUTE ADDED