Laser Galicia S.L.

Laser Galicia S.L. has become one of the references in laser cutting.

Kontakt

Laser Galicia S.L.

Poligono industrial A Granxa parcela, 17

36400 Porriño, Spain

-

Show phone number

+34 986342239

- Show Email

- lasergalicia.com

Contact Person

- German Moa

-

Sales Germany

-

Show phone number

0034 986 342 239

- Show Email

German Chamber of Commerce for Spain

Markus Kemper

Deputy Managing Director | Head of Market Consulting

Phone: (+34) 91 353 09 28

[email protected]

www.ahk.es

Certifications

Quality

Our work is certified according to ISO 9001:2015, IATF 16949: 2016, IAQG EN 9100: 2016, EN 1090-2:2011 and EN 1090-3:2011, EN ISO 3834-2:2006, ISO EN 45001, ISO EN 14001 and UNE EN 15085 standards.

These certifications allow us to offer the best products for vertical markets such as automotive, wind energy, aerospace, architecture, and many others.

Our metrology laboratory is equipped with a 3D measurement arm and a 2D measurement scanner for the most demanding customers.

Quality certificates:

EN-1090-2

EN-1090-3

EN-ISO-3834-2

IAQG-EN-9100

IATF-16949

ISO-9001

ISO EN 45001

ISO EN 14001

UNE-EN 15085

Profile

Galerie

Reference in laser cutting.

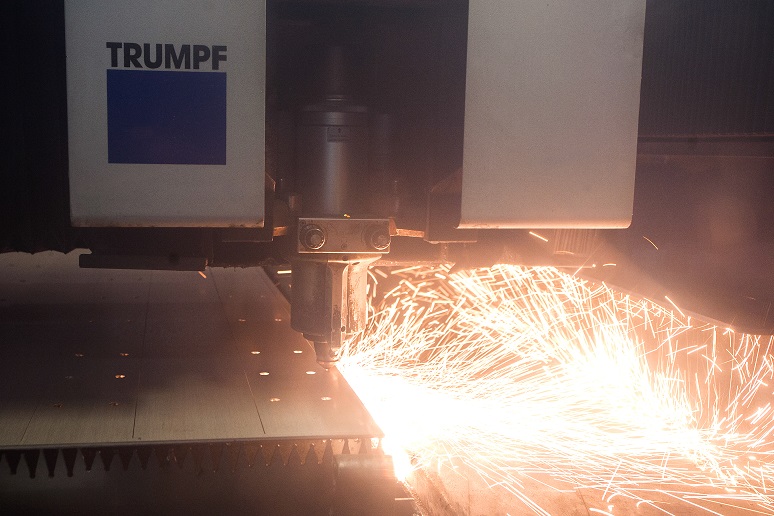

LaserGalicia has become one of the references in laser cutting. The company, established in 2002 within the Laser Ebro Group and born out of the friendship and collaboration in between Pablo Ezquerra Lasheras and Manuel López Rodríguez, distinguishes itself for its bet on the latest TRUMPF technology and its commitment to provide the quickest, most flexible and most reliable service to its clients.

Our aim is to offer our clients tight delivery dates, the highest quality, urgent services, and the possibility of manufacturing from unitary parts to large series.

The Laser Ebro Group is currently the national leader in the sector, counting with 9 plants across the country. Our belonging to the Group is key to the robustness and the future of the company. Furthermore, it allows us to interexchange production with the different plants obtaining a level of security and service that would be unapproachable working as separate entities.

We bet on the most cutting-edge technology

Laser Galicia is a funding partner of the Galician Automotive Cluster (CEAGA), reference cluster in the sector. The goal of CEAGA is that the Galician Automotive Sector reaches a competitive and sustainable leadership position in Europe by 2020.

Laser Galicia also collaborates with UDEGA( Union of Aviation Galician Companies), born in 2012 out of the union of various Galician companies with purpose of unifying working methods and its relations with the external context, to optimize material and human resources by industrial cooperation. Capable of approaching a wide range of projects, UDEGA is established as a reference in the national industrial sector.

Business

Plate Laser Cutting

The plate laser cutting process is characterized by the high precision achieved in every edge of the part, allowing its assembly no additional adjustments, therefore, saving labor hours.

USLC currently operates eight TRUMPF laser cutting machines (CO2 lasers and fiber lasers), enabling us to offer a wide range of cutting possibilities.

The laser cutting process yields the best quality, speed, traceability, and assures at the same time a high level of flexibility that goes from cutting parts with high precision for electronic devices to parts for heavy industry.

Tube Laser Cutting

The tube laser cutting has completely revolutionized the design of metal structures, being able to obtain solutions based on complex geometries that reduce significantly the assembling and welding times, likewise increases the rigidity and quality of the structure.

This type of machines can also work with commercial laminated profiles, making the work with this type of materials much quicker and reliable.

The option of bevel cuts up to 45° widens even more the design capacities and enables the saving in welding times, since it gives the designer the possibility of selecting the characteristics of the contact surfaces.

The high precision, flexibility and speediness of this process, results in a great saving in labour for our clients. Furthermore, it gives us the freedom to design new tube structures that would not be possible using conventional methods.

Bending

An efficient bending section is indispensable to be able to manufacture a huge amount of the designs requested by our customers.

The capacity of obtaining complex geometries by laser cutting, has permitted the replacement of a lot of assembling and welding processes by smart designs that include bends with different radius.

Laser Galicia counts with 11 Numerically Controlled bending machines of latest generation, that working 3 shifts give us a significant production capacity.

Force of press: up to 320m

Length of fold up: up to 4m

Sheet Metal Works

During the last years we have been strengthening our welding facilities in order to offer our clients completely finished assemblies, from plate and tube.

We are capable of doing this works in Carbon Steel, Stainless Steel and Aluminium, and equal to the rest of our sections, we can quote from small batches to large series, thanks to our robot-controlled plant with an ABB robot.

Our welding section is certified by the ISO 3834-2, which guaranties the quality of the process and the finishing.

Finishings: zinc coating, painting, galvanizing, …

Thanks to the extensive network of suppliers existent in our geographic area, we can quote nearly any type of finishing for parts or assemblies, ensuring the same quality and traceability that we provide in the rest of our products.

Video

Products/Services/Offers

Offers

LaserGalicia - Plate Laser Cutting, Tube Laser Cutting, Bending Sheet Metal Works

Plate Laser CuttingThe laser cutting process is characterized for the high precision achieved in every edge of the cut part, allowing its subsequent assembling without any posterior machining or setting, and therefore the consequent saving in labour. Tube Laser cuttingThe tube laser cutting has completely revolutionized the design of metal structures, being able to obtain solutions based on complex geometries that reduce significantly the assembling and welding times, likewise increases the rigidity and quality of the structure. BendingBecause the laser cutting can create complex geometries , it is possible to replace many assembly and welding processes for intelligent designs that includes bends with different radius. Sheet Metal WorksDuring the last years we have been strengthening our welding facilities in order to offer our clients completely finished assemblies, from plate and tube.