EBROACERO, S.A.

EBROACERO, S.A. was founded in 1963 and since then has dedicated its activity to the manufacturing of steel and alloyed castings for many kinds of industrial applications.

Kontakt

EBROACERO, S.A.

C/ Argualas, 20

50012 Zaragoza,, Spain

-

Show phone number

+34 976 564 625

- Show Email

- www.ebroacero.com

Contact Person

- Belén Pérez-Caballero

-

Export Area Manager

-

Show phone number

+34 976 564 625

- Show Email

German Chamber of Commerce for Spain

Markus Kemper

Deputy Managing Director | Head of Market Consulting

Phone: (+34) 91 353 09 28

markus.kemper@ahk.es

www.ahk.es

Certifications

Ebroacero S.A., is a foundry for steel castings. The company's aim is to be the market leader in the supply of castings and machined parts to high standards of quality.

THAT AIM IS TO BE ATTAINED BY:

- Focusing the management of all activities on client satisfaction.

- Managing resources and responsibilities in a rigorous, honest, transparent, and ethical manner.

- Promoting a work environment that favours and encourages the updating and specialisation of human resources, as well as the development of new technologies and processes, and innovative, creative ideas.

- Raising staff awareness of, and training staff in, developing best environmental practices of an operational nature, as well as promoting staff information and training.

- Cultivating a work setting that reduces risks to a minimum, prioritises employee safety, and encourages on-going training in safe practices to employees in relation to their work as well as in matters of health and risks in the workplace.

- Encouraging team-working, creating a setting in which people can give the best of themselves, making people creative, productive, and safe, thus making work pleasurable.

- Building employee loyalty based on merits and values.

- Seeking excellence by applying standards ISO 9001:2015 e ISO 14001:2015.

- Developing a culture of continuous improvement by setting and periodically reviewing quality and enviromnental objectives and targets.

- Complying with all legal, regulatory, and prescriptive requirements.

- Checking all environmental aspects derived from the company's activities, favouring sustainable development within its area of influence.

- Minimising the environmental impact of our activity.

Profile

Galerie

Ebroacero S.A. was founded in 1963 and since then has dedicated its activity to the manufacturing of steel and alloyed castings for many kinds of industrial applications.

Our main objective is customer satisfaction supplying quality products in competitive market conditions and within the agreed delivery dates.

Ebroacero S.A. has modern production and control means together with a highly qualified Technical Staff, whose knowledge is constantly updated.

We meet our domestic and export market customers' semi-heavy and heavy casting needs and count high technology equipment manufacturers among our customers.

Ebroacero S.A. is located in Zaragoza, an important industrial area strategically located between four other industrial capital cities in Spain (Madrid, Barcelona, Valencia and Bilbao).

Business

TECHNICAL OFFICE

This section is at our customers disposal so we can help in the design of the castings. A proper design favours obtaining the quality level required in the specifications.

When a customer entrusts us with the manufacturing of a part, our widely experienced engineers carry out the dimensional, feeder and riser location calculations. They study the best model concept, draw up the plans for their manufacture and define the most suitable moulding process for the kind of part under consideration, indicating important aspects to be kept in mind such as melting speed and temperature, areas of the mould to be protected, etc.

TECHNOLOGY

Providing simulations supports us for choosing the most convenient alternative.

Thanks to a technological support agreement with one of the most important European material research centres, we have highly qualified external consultants at our disposal.

MOULDING

This section has the necessary facilities for preparing sand and resin mixtures used for the manufacture of mouldings and cores. Silica, chromite, zirconium, olivine and other sands are agglomerated with phenol-alkaline and furanic-based resins and catalysts of different origins.

MELTING

Ebroacero S.A. has two basic process magneto-hydraulic regulation electric arc furnaces with inert gas injection from the bottom which allow for the melting of parts of up to, approximately, fourteen tonnes of net weight. Different material qualities are manufactured with these means, such as:

- Carbon steels

- Low alloyed steels

- Martensitic and Austenitic Stainless Steels

- Refractory steels

- Wear resistant manganese steels

- Laminar graphite iron

- Nodular graphite iron

- Wear and abrasion resistant alloyed white iron

- Ni-resist heat and corrosive agent resistant iron

HEAT TREATMENTS

We have the necessary facilities to carry out the heat treatments required by the different kinds of steel. These treatments are:

- Annealing

- Normalising

- Air or water quenching

- Tempering

- Stress relieving

For these tasks there are four furnaces with the following dimensions:

· Mobile rectangular base furnace capable of reaching temperatures of up to 1200ºC with a maximum load of 20 tonnes and measuring 4000 x 3500 x 1970 mm.

· Mobile rectangular base furnace capable of reaching temperatures of up to 1000ºC, with a maximum load of 30 tonnes and measuring 6500 x 3500 x 1700 mm.

· Rectangular furnace capable of reaching temperatures of up to 1200ºC with a maximum load of 3.5 tonnes and measuring 5000 x 1500 x 1700 mm.

· Circular pit furnace capable of reaching temperatures of up to 1000ºC with a maximum load of 30 tonnes and measuring 6000 mm. diameter x 2500 mm. high.

MACHINING

Ebroacero S.A. is aware of customer needs for receiving, either in their facilities or their assembly sites, their parts completely machined. For this reason we have acquired the necessary machines with enough capacity to machine all the parts we manufacture. The maximum capacities of the machine tools at our disposal are the following:

· VERTICAL CNC TURNING MACHINES for parts of a maximum diameter of 8500 mm x 2600 mm. height.

· CNC MILLING MACHINE:

- X=18000mm

- Y=4000mm

- Z=800mm

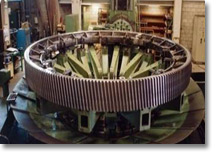

· PROGRAMMABLE GEAR HOBBING MACHINE for gears of a maximum diameter of up to 7060 mm. module 50 and height of 2200 mm.

Downloads

Video

Products/Services/Offers

Offers

PRODUCTS EBROACERO, S.A.

PRODUCTS Cement Plants Fluid Control Power Generation Turbines Naval Industry Siderurgical Plants Mining Public Works Other Equipment PULVOMATIC Crushers Girth Gears