S.T.F. snc di Delti Roberto & Luca

Constructing moulds for plastics MONO-MATERIAL | BI-MATERIAL | TRI-MATERIAL SANDWICH and UNSCREWING MOULDS Constructing zamak die-casting moulds

Kontakt

S.T.F. snc di Delti Roberto & Luca

Via Tiezzo, 12 - 33082 Azzano X Fraz. Corva (PN) Italia

33082 Azzano X Fraz. Corva (PN) , Italy

-

Show phone number

+39 0434647859

- Show Email

- stf-stampi.com

Contact Person

- Luca Delti

-

Show phone number

+39 0434647859

- Show Email

AHK Italy

Mrs. Barbara Maldari

Phone: +39 02 39800931 /

+39 340 9624147

[email protected]

www.ahk.it

Profile

Galerie

STF S.n.c. was founded in 1981 in Azzano Decimo (Pordenone, Italy).

We specialise in constructing moulds for plastics and zamak die-casting, and have consolidated experience in producing mono-material, bi-material, tri-material, sandwich and unscrewing moulds.

The STF team of qualified technical staff is on hand to help transform your problems into innovative solutions.

The work of our skilled staff is supported and enhanced by the use of advanced, industry 4.0 technologies, in which the company has always invested and which support our team every day in creating designs, and increasing the efficiency and value of the end result.

STF has been a competent supplier since the beginning, accompanying you from the product co-design stage, through to the final product design, creation and maintenance over time. This process ensures ideas are developed paying close attention to the look and functionality of the end product.

Business

Co-Design

Each project starts with your idea

We add our skills to create a concrete, sustainable project that pays particular attention to aesthetic and functional aspects. As part of this we also carry out a feasibility study.

Our knowledge of the full production process up to moulding the product means that we can let you know about any critical issues that may arise while creating the product, at the initial co-design stage.

Our technicians are available to help perfect your design idea and improve the technical and functional aspects.

Design

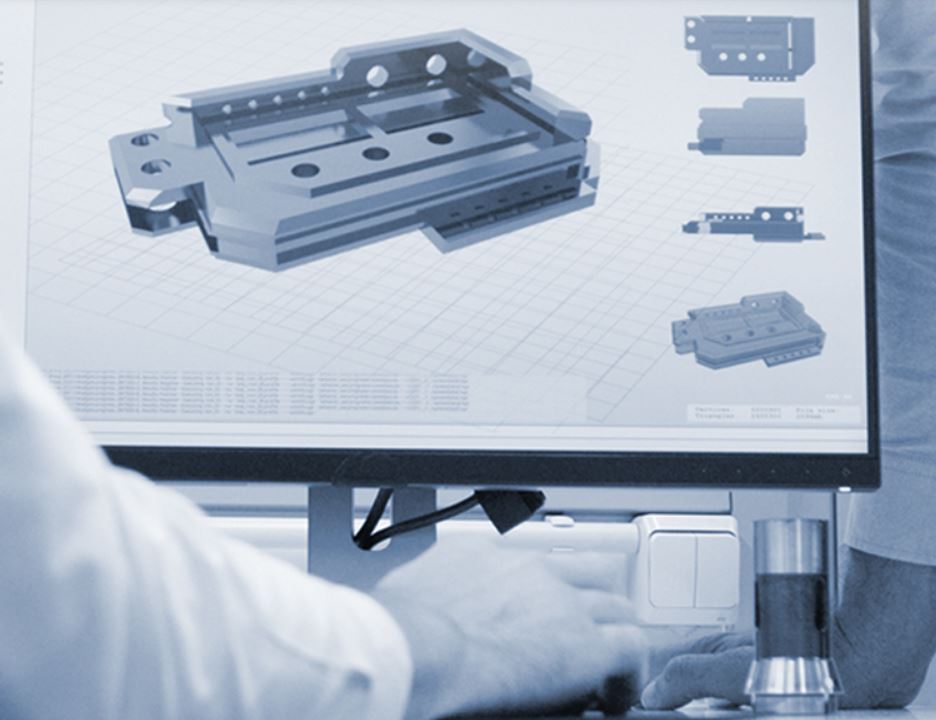

The technical department can work with any interface using systems such as 3D NX and Solidworks for the design process, and Work NC and Mastercam for 3/5-axis CAM programming (including continuous).

At this stage, the final design is engineered by our technicians who create 3D product designs, which also take into account all the technical and functional aspects of the project (operating requirements, ergonomics, electronic housing, etc.).

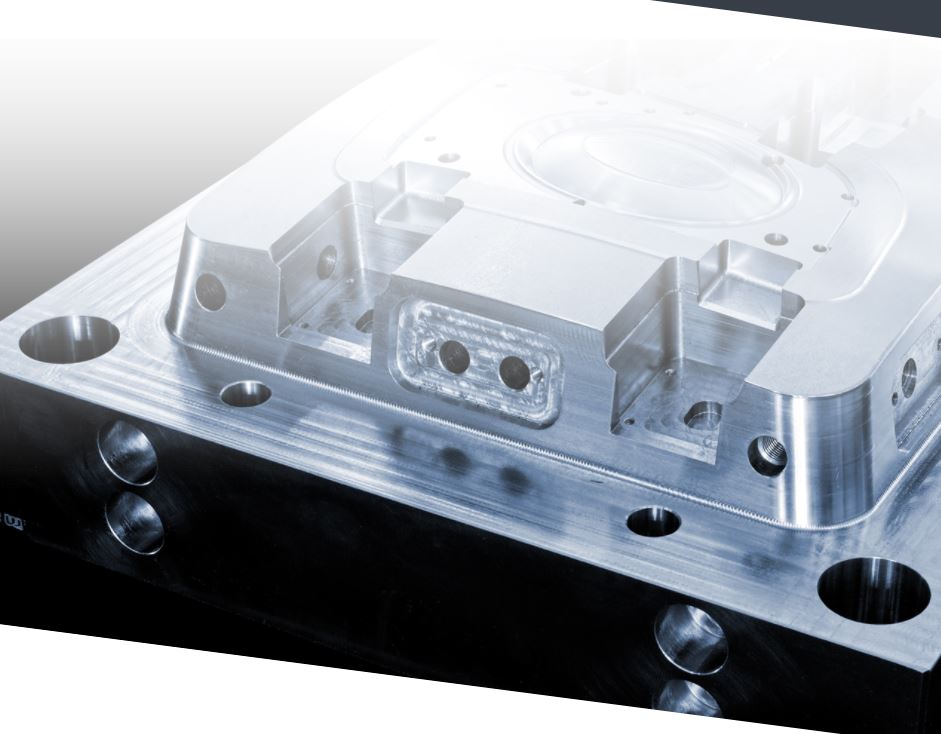

Constructing moulds for plastics and zamak die-casting

STF is specialised in constructing mono-material, bi-material, tri-material, sandwich and unscrewing moulds for plastics, as well as moulds for zamak die-casting.

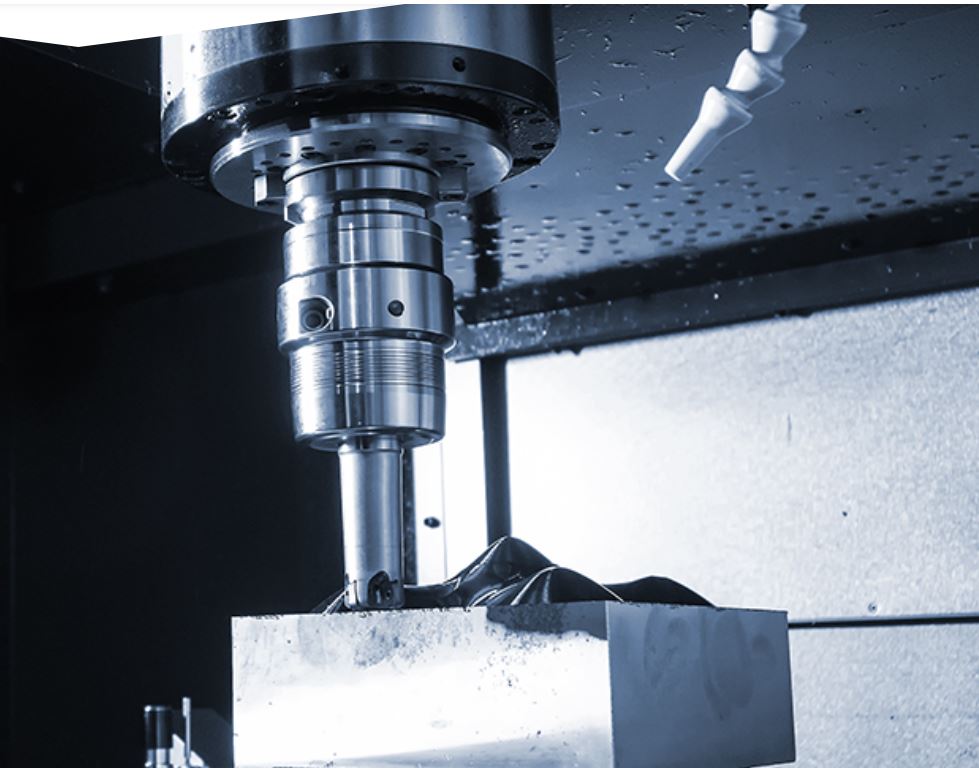

STF produces moulds up to 12,000 kg, thanks to its production area which includes latest-generation 3 and 5-axis machining centres. Constant equipment control and monitoring allows us to provide timely compliance feedback for the work we carry out.

Pre-production testing

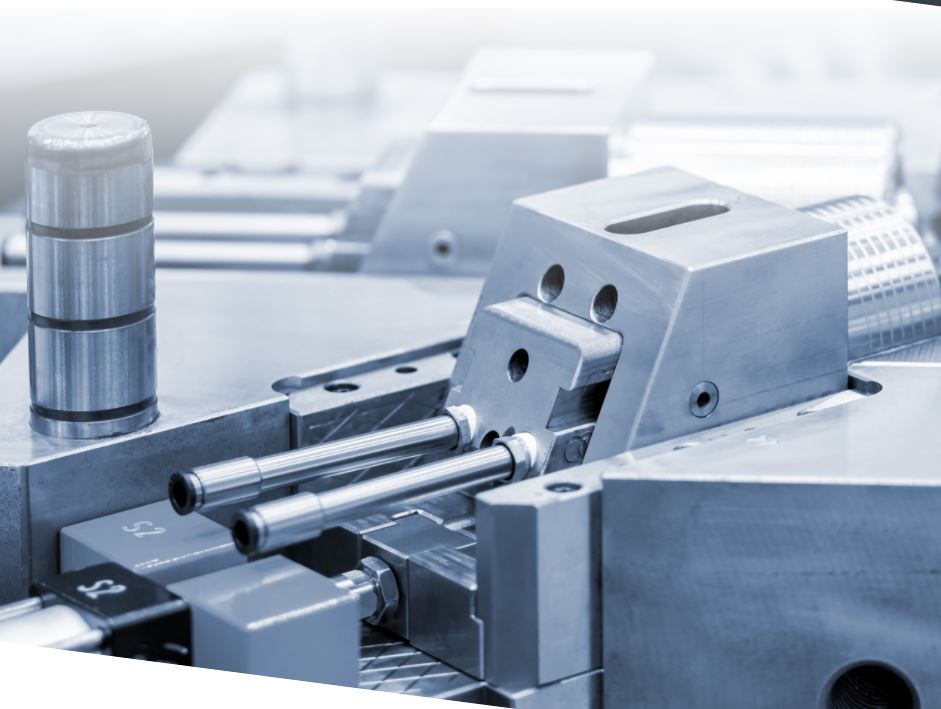

On request, STF guarantees a testing service for the final mould product and a pre-production mould.

This is a strategic part of the process, as it allows us to pre-empt any problems and fine-tune the mould as necessary, within the timeframe agreed on together.

Maintenance

STF is always at the customer's side, even after the project has been completed. Maintenance ensures a longer service life of the mold, despite the intensive production cycles it undergoes.

The maintenance allows maintaining a high quality standard of the final product.

The company is able to perform maintenance and modifications even on molds not manufactured by STF.

Downloads

-

Brochure S.T.F. sncWe specialise in constructing moulds for plastics and zamak die-casting, and have consolidated experience in producing mono-material, bi-material, tri-material, sandwich and unscrewing moulds.

Video

Products/Services/Offers

Products/Services

AUTOMOTIVE

AUTOMOTIVESTF designs and manufactures parts for front and rear 1K-2K headlights, chrome-plated fixtures, internal and external aesthetic fittings, and many types of mechanical parts

VENDING MACHINES

VENDING MACHINESSTF manufactures moulds for producing aesthetic fittings and internal parts for coffee machines, pods, tills and vending machines

HOME AUTOMATION

HOME AUTOMATIONSTF designs and manufactures moulds for aesthetic and non-aesthetic fixtures for security systems, burglar-alarm systems, fire-safety systems and thermostats

HOME INTERIORS

HOME INTERIORSThanks to our flexibility, experience in co-design and design, STF also manufactures moulds for furniture and furnishings, as well as other household items of different sizes and shapes.

Offers

PACKAGING

PACKAGINGSTF manufactures moulds for producing containers in a wide range of sizes and designs for many uses, including food packaging and storage