Epalfer - Serralharia de Moldes, Cunhos e Cortantes, Lda.

EPALFER is one of the best European independent Toolmaker. We develop, produce and test high quality and complex tools for stamping steel up to 1200 Mpa, Aluminum, Inox and Titanium.

Kontakt

Epalfer - Serralharia de Moldes, Cunhos e Cortantes, Lda.

Zona Industrial das Barrozinhas

3750-742 Águeda , Portugal

-

Show phone number

+351 966 772 378

- Show Email

- www.epalfer.com

Contact Person

- ALEXANDRE MATEUS

-

Commercial Technician

-

Show phone number

+351 966 772 378

- Show Email

Deutsch-Portugiesische Industrie-und Handelskammer / AHK Portugal

Helga Barreiros

Koordination Services | Abt. Markt- und Absatzberatung

Coordenadora de Serviços | Dpt. Consultoria de Mercado

Tel. +351 21 1211510 / 934 890 651

[email protected]

www.ccila-portugal.com

Turnover

7MVAT number

PT505884267Participation in Exhibitions

GACS - StuttgartReferences

Certifications

ISO 9001

Profile

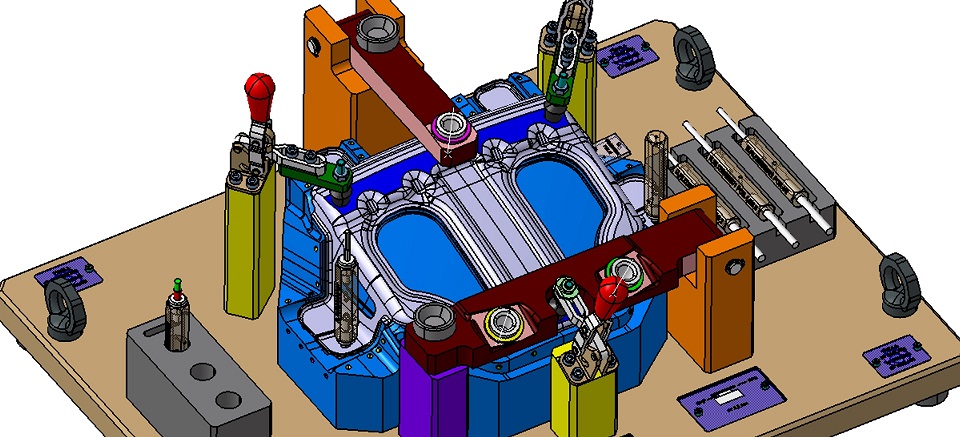

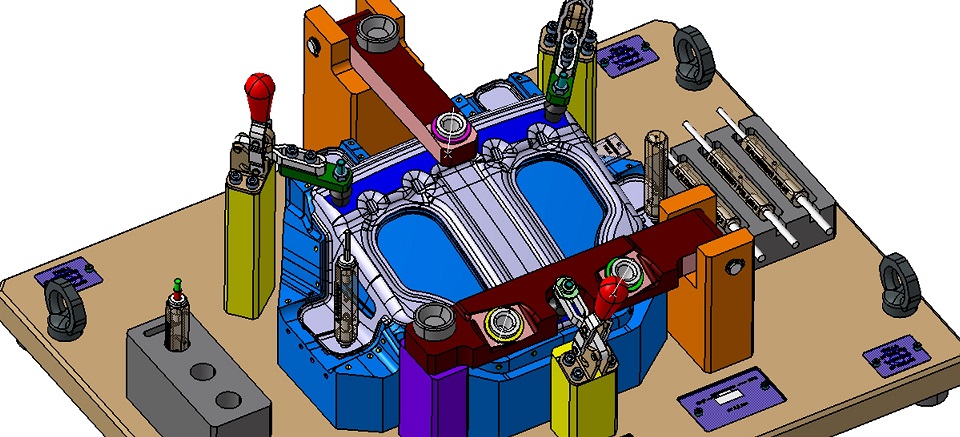

Galerie

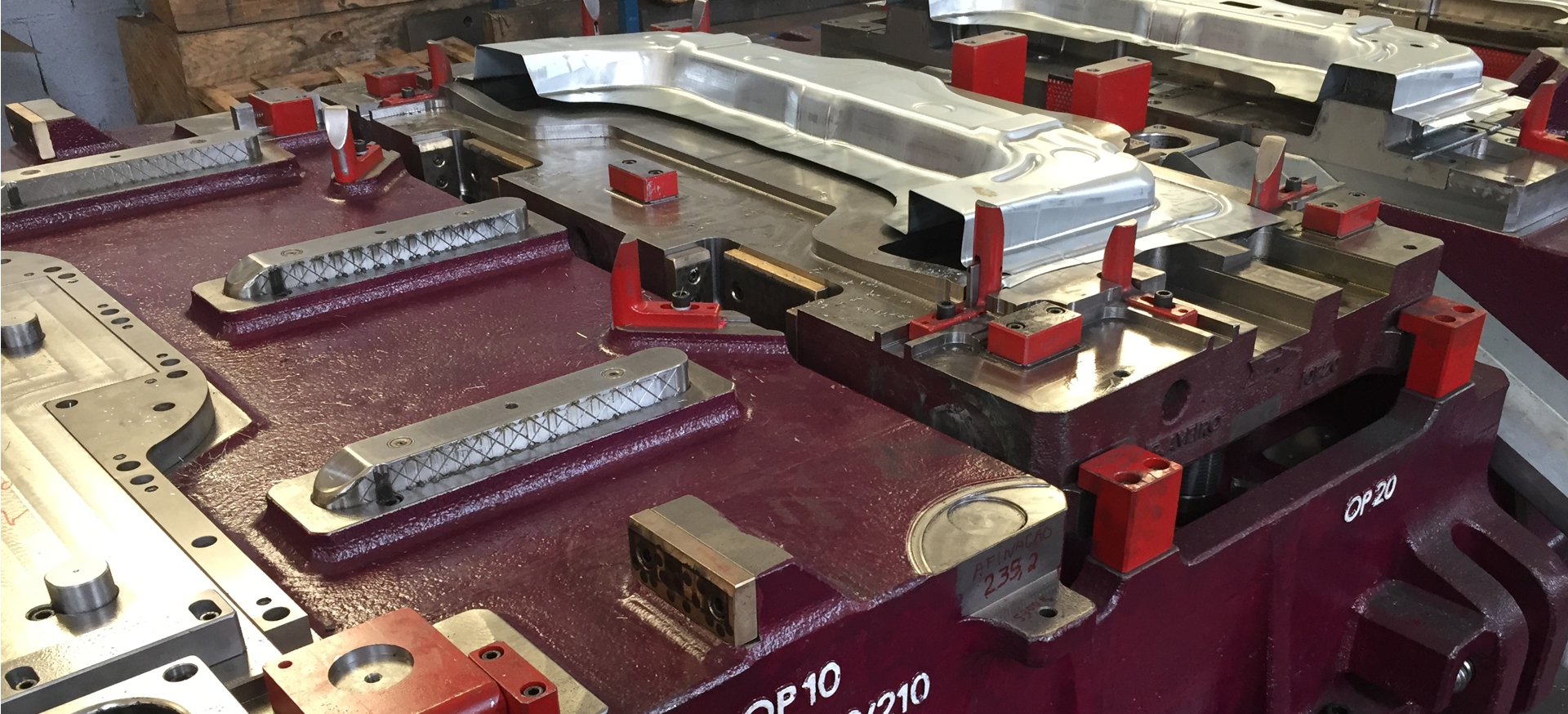

EPALFER is one of the best European independent Toolmaker.

We develop, produce and test high quality and complex tools for stamping steel up to 1200 Mpa, Aluminum, Inox and Titanium.

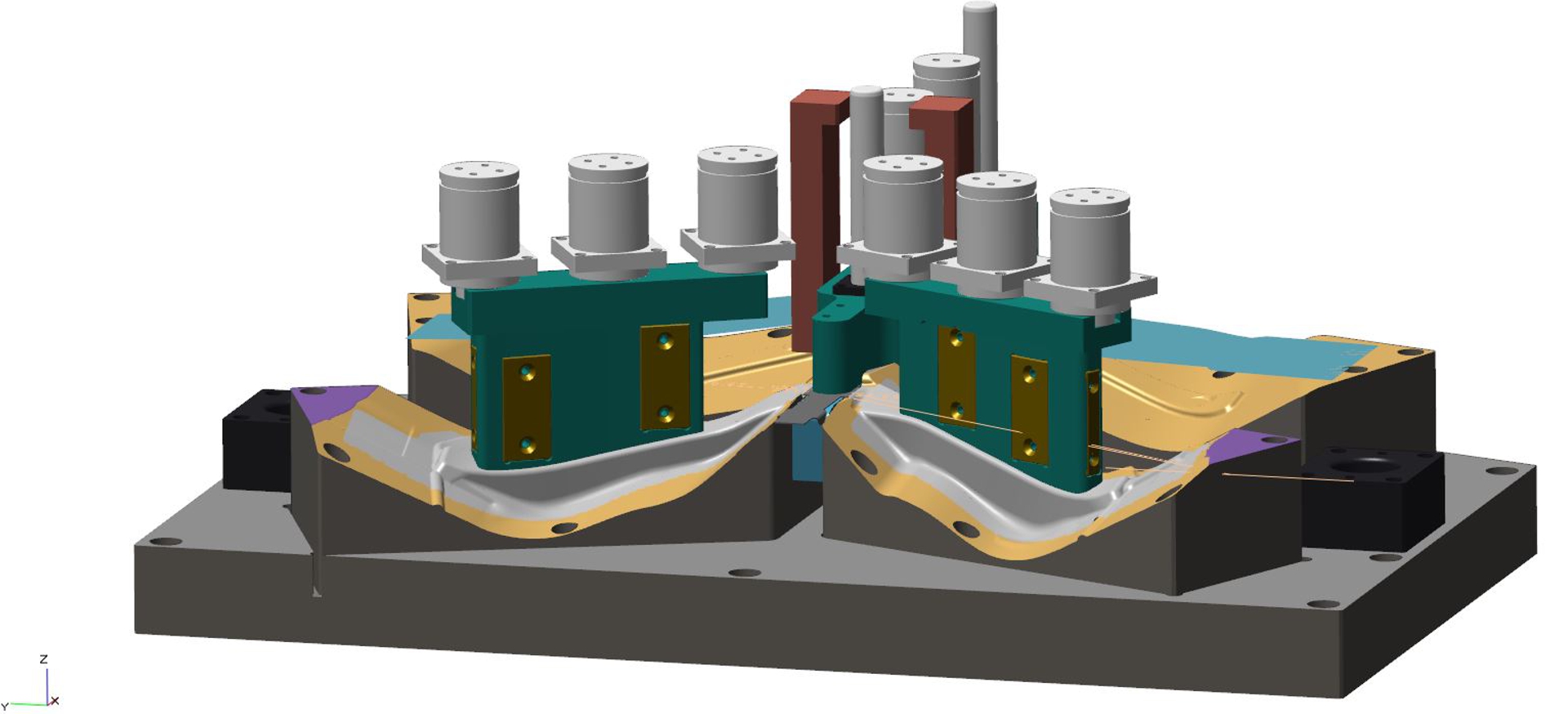

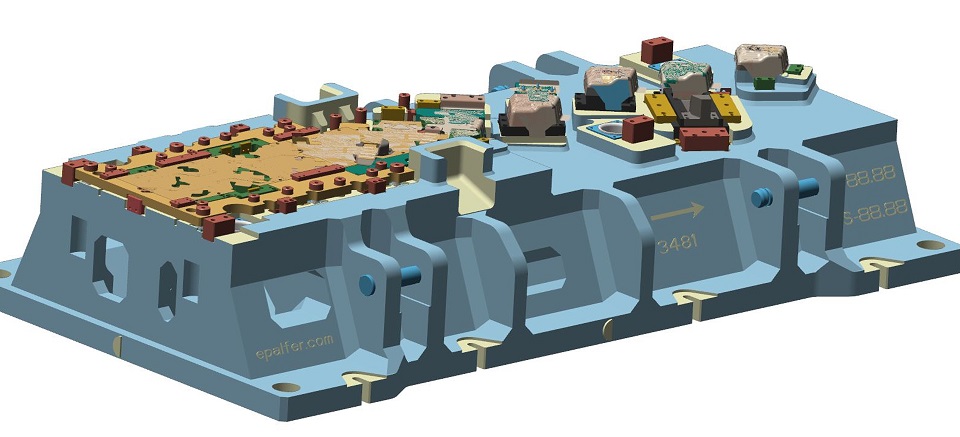

Progressive, Transfer and Tandem Tools up to 6000 x 2200 x 1300mm and weighting up to 50ton are fully made internally.

Our main costumers are OEM'S and TIER 1.

Using the most advanced technology and equipment we ensure a continuous growth and presence in the world’s leading automotive tooling marketplace.

Constant training of our 95 employees ensures quality and commitment to our clients demands.

We will be pleased to guide you in a visit to our company !!!

Business

Products

Prototyping

We develop with our costumer simulating study to check parts feasibility in early stage. To reproduce real parts, “white tools” or drawing operation for end production tooling is manufactured in short time either for 1 or 1000 parts. Using 5 axis laser cutting and 5 axis machining, we ensure accurate contour of the parts to produce.

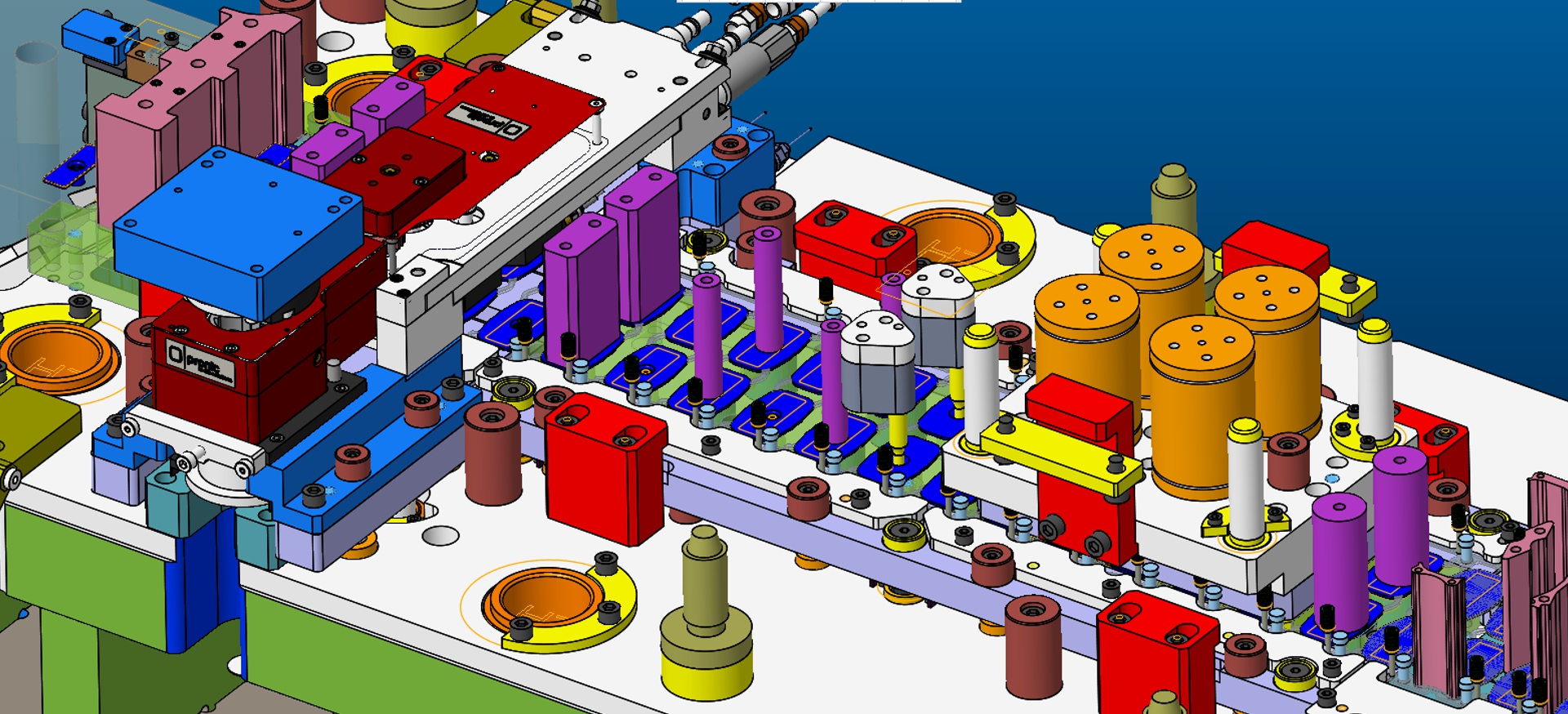

Progressive Tooling

Epalfer is highly experienced with Progressive Tooling from medium to high complex parts up to 1600mm width. We have produced Progressive Tooling with:

- Tapping units ( vertical/horizontal);

- Insertion of nuts, screws and bushing;

- In die “Tox” clinching, etc.

Our costumers can expect to achieve the maximum productivity/quality from our progressive tools.

Transfer

Transfer and Tandem tooling are used in medium-sized to large-sized components whose geometry does not allow production in progressive dies. We supply transfer and tandem tooling for presses up to 2000Ton and 6000mm length.

We develop and study the Transfer Bars Kinematics or integrate it from another supplier ( example: Springer, Destaco, Misati, etc.). Our main Casting suppliers deliver us casted elements between 5-6 weeks. Welded structures can be produced in 2 weeks.

Hybrid Tools

One of our core business is to develop tools that integrate progressive steps with transfer operations ( Hybrid Tooling ). This way we can minimize material consumption to the minimum for complex geometry parts. Either with standard transfer or mechanical transfer (more strokes per minutes) we develop the best solution for our costumers.

Fixtures

On request we are able to manage the supply of fixtures and control gauges for the parts produced by our tools.

References

Downloads

Products/Services/Offers

Products/Services

Products

Products PrototypingWe develop with our costumer simulating study to check parts feasibility in early stage. To reproduce real parts, “white tools” or drawing operation for end production tooling is manufactured in short time either for 1 or 1000 parts. Using 5 axis laser cutting and 5 axis machining, we ensure accurate contour of the parts to produce. Progressive ToolingEpalfer is highly experienced with Progressive Tooling from medium to high complex parts up to 1600mm width. We have produced Progressive Tooling with: Tapping units ( vertical/horizontal); Insertion of nuts, screws and bushing; In die “Tox” clinching, etc. Our costumers can expect to achieve the maximum productivity/quality from our progressive tools. TransferTransfer and Tandem tooling are used in medium-sized to large-sized components whose geometry does not allow production in progressive dies. We supply transfer and tandem tooling for presses up to 2000Ton and 6000mm length. We develop and study the Transfer Bars Kinematics or integrate it from another supplier ( example: Springer, Destaco, Misati, etc.). Our main Casting suppliers deliver us casted elements between 5-6 weeks. Welded structures can be produced in 2 weeks. Hybrid ToolsOne of our core business is to develop tools that integrate progressive steps with transfer operations ( Hybrid Tooling ). This way we can minimize material consumption to the minimum for complex geometry parts. Either with standard transfer or mechanical transfer (more strokes per minutes) we develop the best solution for our costumers. FixturesOn request we are able to manage the supply of fixtures and control gauges for the parts produced by our tools.