Niho Motors d.o.o.

NIHO MOTORS is today one of the leading companies in Bosnia and Herzegovina, in the field of production automatic lathes, assembling components, and welding.

Kontakt

Niho Motors d.o.o.

Varad br.3

88400 Konjic , Bosnia and Herzegovina

-

Show phone number

00387 36 728 460

- Show Email

- nihomotors.com

Contact Person

- Adnan Alikadić

-

Sales Manager

-

Show phone number

00387 61 013 617

- Show Email

Nihad Alikadić

Phone: 00387 61 106 252

Mirza Karahodža

Delegation of German Economic Affairs in Bosnia and Herzgegowina

Predstavništvo njemačke privrede u Bosni i Hercegovini

T: +387 33 295 911

E-mail: [email protected]

References

Certifications

ISO 9001 -2015

Profile

Galerie

NIHO MOTORS is today one of the leading companies in Bosnia and Herzegovina, in the field of production automatic lathes, assembling components, and welding.

Our team consists of about 15 highly motivated and professionally trained staff. The machinery consists of more than 18 automatic lathes with feeders. Manufacturing, office and warehouse facilities are over 900 m2.

Business

CNC TURNING

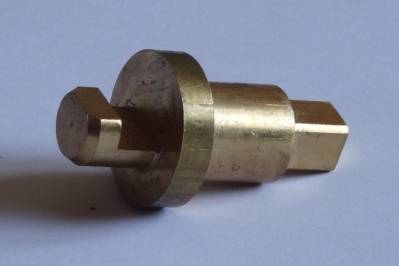

In the production area of 400 m2, is 7 CNC lathes. Please note that all machines have feeders for the operation of bars (hydro feeders or feeder FMB). The products that we do have a diameter of 2 to 100mm, and the preparation of the bars is to 75mm diameter, the specimens are mostly medium complexity.

The materials used to manufacture parts are steel, stainless steel - materials of aluminum, plastic, brass, copper etc.

Our CNC machining centers for turning the Mazak, INDEX or WEILER, and photos of machines you can see in our gallery. In the production area of over 200 m2 is located 9 Single-spindle automatic lathes of line brand INDEX A dimension of 2-25 mm. Please note that these machines are used for simpler products and large-sized series, and where a lower price products. maximum specimen size of the bars is 25 mm in diameter and lengths up to 60 mm, and specimens are mostly medium complexity. In the production area of over 220 m2 are located 3 šestvretena automatic channel brand Schütte dimensions 16-20 mm. Please note that these machines are used for simpler products big series, and where a lower price products. The maximum specimen size of rods up to 20 mm diameter and a length of up to 60mm, and the specimens are mainly medium complexity.

All machines are fully equipped, and there are all He needs backing machines been successfully monitoring and maintenance production. For finišne works we own machines for milling, drilling, threading and thread rolling, injection. Plan for future investment the multi-axis CNC machining center for milling, turning and milling.

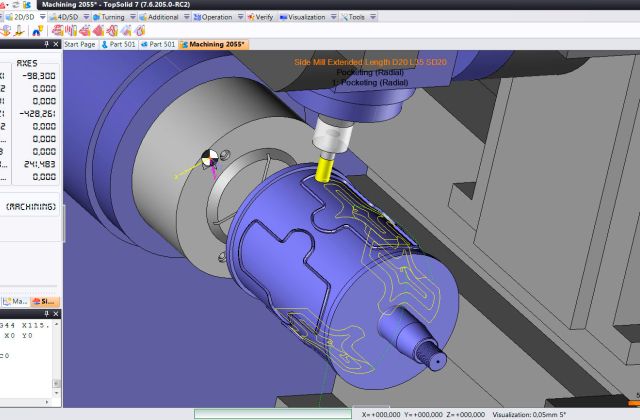

CAD-CAM programming

Serious production today is unthinkable without CAD-CAM technology, and so we follow the latest trends in this area, investing in new software and training of our CAD-CAM programmers.

Gaining CAD draft of the customer maximum optimized making and minimize "idles" our CNC machining centers, and therefore the price of the final product. Production with CAD drawings has another advantage, which is that the necessary communication about technical issues and any ambiguities or missing dimension to the draft, between you as the customer and the customer, and us as manufacturer, is also minimized, which in turn saves valuable time and money.

As for the CAD software we are working in AutoCAD, and planned next investment in Solid Works and Solid Edge. From CAM software do most MASTERCAM-in. Our plan in the near future to go to the CAM software in the top Hermle 5-axis machining center for milling, which guarantee high precision and converting each of your, even the most complex ideas into reality as soon as possible. Possibility of 5-axis 3D milling is another reason why choose us as a partner for parts CNC CAD-CAM technologies.

We will gladly help and advice if possible simpler, easier and quicker develop certain parts and functions that remain the same or better than before.

SERVICES

COMPANY NIHO-MOTORS DOO KONJIC OFFERS THE FOLLOWING SERVICES:

Elements Finishing

- Mounting Assemblies

- Organization of Transport

- Coating Parts

Industry Focus

The produced parts are used in:

- Auto industry

- Elektro industry

- Furniture Industry

- A dedicated industry (military industry)

- Medical technology

- Engineering and many other industries

Customers with whom we work today are in:GERMANY, AUSTRIA, SWITZERLAND, ENGLAND, DENMARK, SWEDEN and SLOVENIA.

References

Products/Services/Offers

Products/Services

CAD-CAM programming

CAD-CAM programmingSerious production today is unthinkable without CAD-CAM technology, and so we follow the latest trends in this area, investing in new software and training of our CAD-CAM programmers. Gaining CAD draft of the customer maximum optimized making and minimize "idles" our CNC machining centers, and therefore the price of the final product. Production with CAD drawings has another advantage, which is that the necessary communication about technical issues and any ambiguities or missing dimension to the draft, between you as the customer and the customer, and us as manufacturer, is also minimized, which in turn saves valuable time and money. As for the CAD software we are working in AutoCAD, and planned next investment in Solid Works and Solid Edge. From CAM software do most MASTERCAM-in. Our plan in the near future to go to the CAM software in the top Hermle 5-axis machining center for milling, which guarantee high precision and converting each of your, even the most complex ideas into reality as soon as possible. Possibility of 5-axis 3D milling is another reason why choose us as a partner for parts CNC CAD-CAM technologies. We will gladly help and advice if possible simpler, easier and quicker develop certain parts and functions that remain the same or better than before.

Services Niho Motors d.o.o.

SERVICES COMPANY NIHO-MOTORS DOO KONJIC OFFERS THE FOLLOWING SERVICES: PARTS FINISHINGNiho Motors, besides manufacturing, offers and mounting parts in assemblies. Today we manufacture and assemble several different circuits. We are always ready to organize production and installation for the needs of our customers. Except for our manufactured parts, assemblies consist of the purchase of parts (standard bolts, etc ...) that for purposes of assembly procures our purchasing department. Indulge mounting assemblies and parts procurement of purchase to us, we will do it for You! MOUNTINGNiho Motors, besides manufacturing, offers and mounting parts in assemblies. Today we manufacture and assemble several different circuits. We are always ready to organize production and installation for the needs of our customers. Except for our manufactured parts, assemblies consist of the purchase of parts (standard bolts, etc ...) that for purposes of assembly procures our purchasing department. Indulge mounting assemblies and parts procurement of purchase to us, we will do it for You! Organization of TransportKanban is a simple visual tool for the management of supply, based on a system of drawing just in time (Just in Time), signaling what is needed, when needed, where needed in the right quantity. Kanban means information that initiates an action or an instruction for replenishment. Kanban is a Lean method that relies on the concepts of standardized work, 5S and visual management for example. to give hospitals a simple but effective way to manage deliveries and inventories. The goal Kanban- system is to support patients and employees, providing needed supplies in the right place at the right time. Kanban is a visual signal that is used to initiate action. Kanban is a Japanese word. Roughly translated means "tab you can see. '" The most important factors of competitiveness in the market, the quality of which is still imperative, are price and delivery time. How would you and in this area were a step ahead of the competition, we have the ability Kanban deliveries. Kanban deliveries have many advantages, among other things: • Reducing the cost of paperwork and administrative costs • The production of large quantities of reducing production costs, and therefore the final workpiece • No storage costs • Also available on the desired day, if necessary, directly in assembly • Constant quality control If you have a solution that suits you more, please contact us, we will listen to your desires, and adapt to them as much as possible. SURFACE PROTECTIONBesides manufacturing parts, and their eventual assembly into circuits, we offer surface protection of parts. We offer a complete service, and will after the machine-made parts, for you do the same to protect the surface. We can offer almost all surface protection, which for us working in the company SUR-TEC EUROSJAJ Konjic: Anodized chromate Tinning Nickel Browning Painting Electropolishing The nitration and many other

Offers

CNC TURNING - Niho Motors d.o.o.

CNC TURNING In the production area of 400 m2, is 7 CNC lathes. Please note that all machines have feeders for the operation of bars (hydro feeders or feeder FMB). The products that we do have a diameter of 2 to 100mm, and the preparation of the bars is to 75mm diameter, the specimens are mostly medium complexity. The materials used to manufacture parts are steel, stainless steel - materials of aluminum, plastic, brass, copper etc. Our CNC machining centers for turning the Mazak, INDEX or WEILER, and photos of machines you can see in our gallery. In the production area of over 200 m2 is located 9 Single-spindle automatic lathes of line brand INDEX A dimension of 2-25 mm. Please note that these machines are used for simpler products and large-sized series, and where a lower price products. maximum specimen size of the bars is 25 mm in diameter and lengths up to 60 mm, and specimens are mostly medium complexity. In the production area of over 220 m2 are located 3 šestvretena automatic channel brand Schütte dimensions 16-20 mm. Please note that these machines are used for simpler products big series, and where a lower price products. The maximum specimen size of rods up to 20 mm diameter and a length of up to 60mm, and the specimens are mainly medium complexity. All machines are fully equipped, and there are all He needs backing machines been successfully monitoring and maintenance production. For finišne works we own machines for milling, drilling, threading and thread rolling, injection. Plan for future investment the multi-axis CNC machining center for milling, turning and milling.