ESR Systemtechnik GmbH

ESR Systemtechnik GmbH is your competent partner for networked automation solutions in production, no matter if it is about virtual computer solutions or the visual appearance of process graphics.

Kontakt

ESR Systemtechnik GmbH

Waiblingerstr. 56

70734 Fellbach, Germany

-

Show phone number

+49 711 510 993 60

- Show Email

- esr-systemtechnik.com

Contact Person

- Weng Alexander

-

Managing Director

-

Show phone number

+49 711 51099370

- Show Email

CEO / Chairman

Alexander WengTurnover

1,3 Mio EURVAT number

D815066597Offices

Fellbach / GermanyYear of founding

2009References

Evonik Operations GmbH - DCS Engineering & Service at several german plants

Sasol Germany GmbH - DCS & PIMS

Porsche AG - SCADA Engineering Paint Shop

Südwestdeutsche Salzwerke AG - MES & SCADA Engineering all sites

Certifications

IOS 9001

Profile

Galerie

Who we are

ESR Systemtechnik GmbH is your competent partner for networked automation solutions in production, no matter if it is about virtual computer solutions or the visual appearance of process graphics. In 2009, ESR Systemtechnik was founded as a system integrator for process control technology. The employees of the first hour were all experienced technicians and engineers who have been working for many years with control and automation technology in the chemical, food processing and power generation industries. ESR continues to serve customers in these industries with engineering, repair and service for existing control system solutions.

Over the years, however, our scope has expanded. Not only have we added new customers from other industries, but we have also added new areas of expertise. The area of software engineering was established with the certification as Wonderware System Integrator in 2010 and has developed strongly since then. From the very beginning, ESR has focused on the networking of production plants and created solutions for machine and production data acquisition (MDE / BDE) or manufacturing execution systems (MES) with the Wonderware system platform. Much of what is propagated today under the keywords IoT or Industry 4.0, we have already implemented in 2011 and 2012 at our customers as production networking. In the meantime, we have built up extensive expertise and programming competence in the area of SQL databases, Visual Studio & .NET, web-based solutions based on Angular & Node.js as well as development and programming of OPC solutions. Our claim is to develop individual and robust solutions for our customers, with which the software solutions, machines and plants existing in grown production landscapes can be networked with each other.

With the implementation of the software solutions for networked production, our customers also quickly requested the associated hardware solution. It was clear to us that it did not make sense to supply physical hardware for such complex projects. Thus began the entry into the virtualization of client and server structures. Since 2012, ESR Systemtechnik has been a Professional Solution Partner of VMware, the market leader in virtualization solutions. Today, we implement high-availability clusters for PDC / MDC applications at our customers, so to speak as an edge cloud solution, on which not only data is recorded and collected, but also pre-processing and analysis is performed. Here, ESR supplies complete network cabinets with switches, servers, UPS and, if necessary, clients as operator stations as well as the associated documentation. In addition, we offer backup & replication solutions on customer request to be protected against data loss.

We are also happy to take on your projects and challenges if you want to transfer your production landscape step by step into the networked world of Industry 4.0 and the Industrial IoT (Internet of Things).

Business

Automation technology is a matter of trust

Whether process control technology, virtualization or visualization, we will find a solution for you

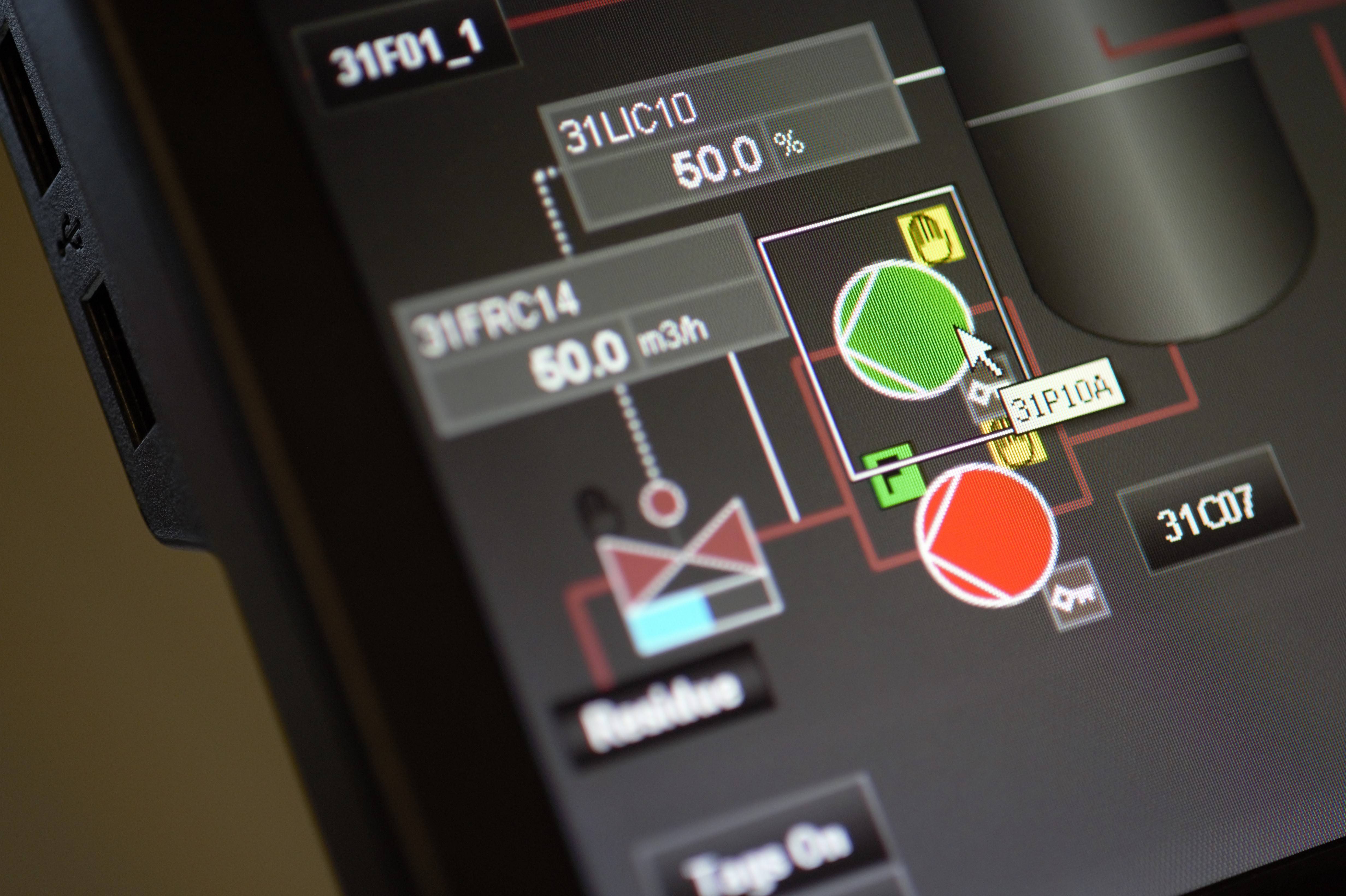

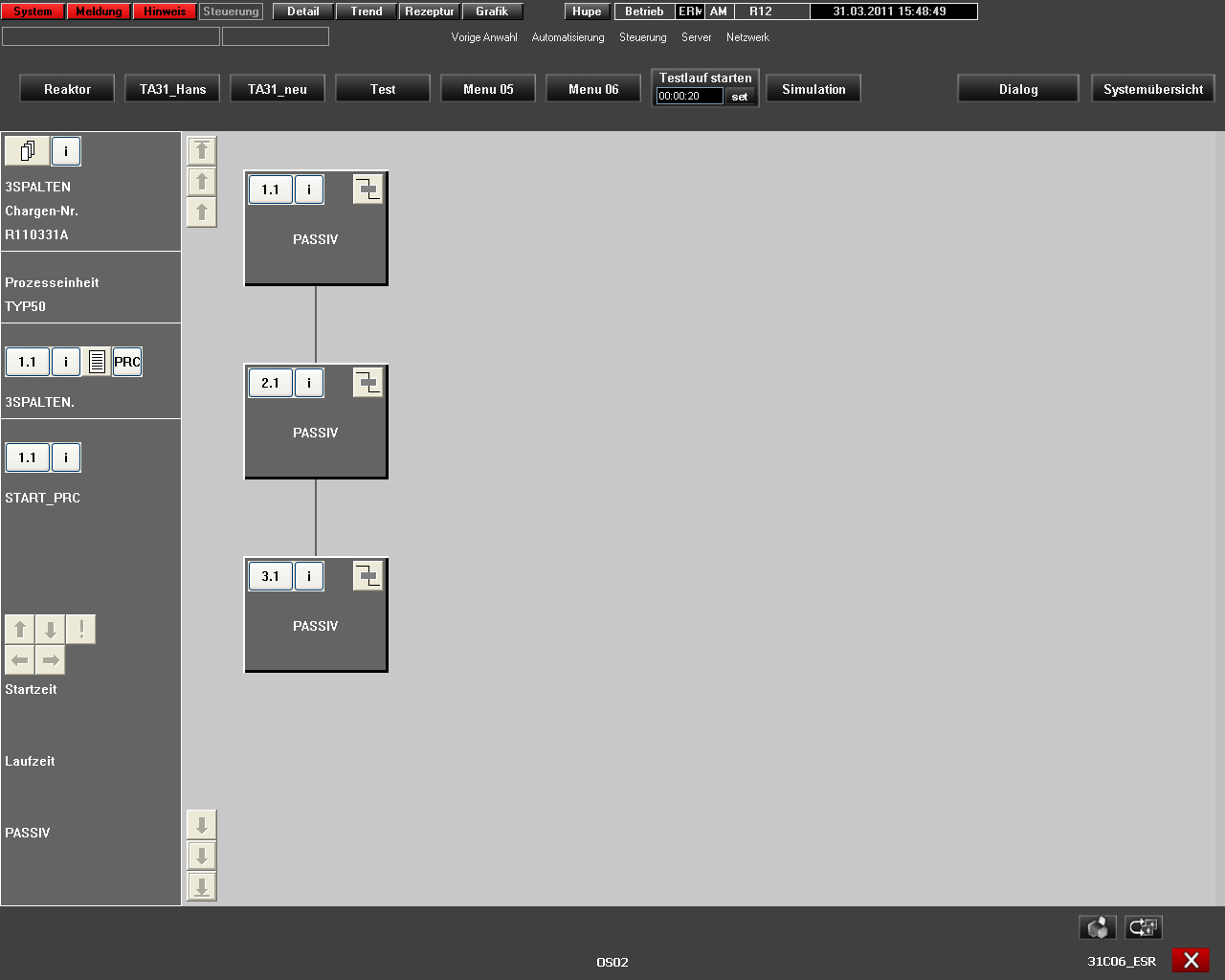

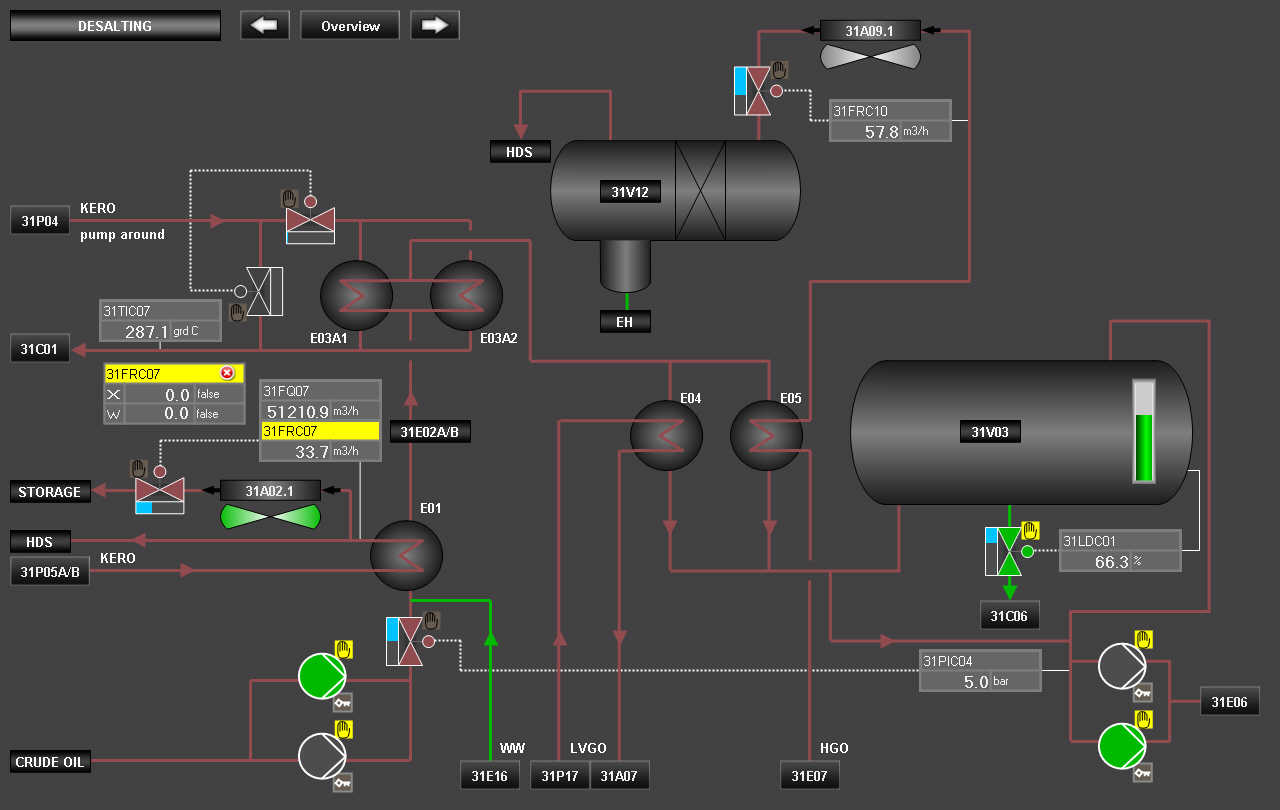

Home of PLS80E

PLS80E is a process control system developed in Germany. With its redundancy concept, its recipe control according to Namur, its vector-oriented process graphics, decentralized computer modules and its PC-based operation, PLS80E has been established on the market since the end of the 1980s.

ESR Software Tools

ESR software tools help you solve a wide variety of tasks within process control engineering. These include historization of trend data, alarm management and much more. Currently adapted to the PLS80E process control system, adaptation to other process control systems is possible at any time.

HMI & SCADA know-how

Do you need a panel visualization for a machine HMI, a remote operator station for a plant or a control system for your production with centralized or decentralized control rooms? ESR will work with you to develop the right solution to meet your individual requirements.

Virtualization with VMware

For virtualization we rely on VMware technologies. This is the creation of a software-based (virtual) component instead of a hardware-based (physical) one. Applications as well as servers, storage and networks can be virtualized.

Our hardware offer

Our offer includes server and network cabinets, control cabinets, servers and clients, uninterruptible power supplies (UPS) and last but not least repairs of all PLS80E components including all cluster IO modules.

Service, Repairs & PLC

We also offer help and programming solutions for Siemens and Triconex PLCs, standby solutions for the PLS80E process control system and repairs around the PLS80E hardware. This also includes the repair of Cluster IO modules.

Industry Focus

- Chemical - DCS, Batch, MES, Historian, PLC, HMI, SCADA

- Automotive - PLC, HMI, SCADA, Robot, MES

- Food & Beverage - PLC, HMI, SCADA, Robot, MES

- Pharma - PLC, DCS, Batch, HMI, SCADA,

References

Evonik Operations GmbH - DCS Engineering & Service at several german plants

Sasol Germany GmbH - DCS & PIMS

Porsche AG - SCADA Engineering Paint Shop

Südwestdeutsche Salzwerke AG - MES & SCADA Engineering all sites

Downloads

-

VISUALIZATION of safety-related control systemsReplacement of old Eckardt AG 19" MUS/TV, new variant 2020 Pink-compatible replacement of old Eckardt MUS/TV by devices of different manufacturers Issue: January 30, 2020

-

PLS80E - Future-proof with PLS80E Release >8.1With the Wonderware System Platform, operating data can be flexibly recorded, MES applications implemented or process data archived.

-

ESR competencesRead more about our competences and references

Products/Services/Offers

Products/Services

PLC Programming

PLC programming for Siemens Simatic S7 with STEP 7 or TIA Portal. We also program with CODESYS.

SCADA & HMI Programming

We create comprehensive SCADA and HMI solutions with AVEVA Wonderware Intouch or System Platform. We also work with Siemens WinCC Pro, Advanced or Unified. As a simple web-based HMI solution we use atvise. Our solutions can be found in the building services, automotive, food & beverage, pharmaceuticals and chemical industries.

Robot Programming

We program mid-size robots (up to 30 kg stroke load) and cobots. We also program the necessary safety chain for the robot cell or cobot application. The HMI for the panel operation can also be created by us.

Offers

ESR Systemtechnik GmbH - Automation technology is a matter of trust

Automation technology is a matter of trustWhether process control technology, virtualization or visualization, we will find a solution for you Home of PLS80EPLS80E is a process control system developed in Germany. With its redundancy concept, its recipe control according to Namur, its vector-oriented process graphics, decentralized computer modules and its PC-based operation, PLS80E has been established on the market since the end of the 1980s. ESR Software ToolsESR software tools help you solve a wide variety of tasks within process control engineering. These include historization of trend data, alarm management and much more. Currently adapted to the PLS80E process control system, adaptation to other process control systems is possible at any time. HMI & SCADA know-howDo you need a panel visualization for a machine HMI, a remote operator station for a plant or a control system for your production with centralized or decentralized control rooms? ESR will work with you to develop the right solution to meet your individual requirements. Virtualization with VMwareFor virtualization we rely on VMware technologies. This is the creation of a software-based (virtual) component instead of a hardware-based (physical) one. Applications as well as servers, storage and networks can be virtualized. Our hardware offerOur offer includes server and network cabinets, control cabinets, servers and clients, uninterruptible power supplies (UPS) and last but not least repairs of all PLS80E components including all cluster IO modules. Service, Repairs & PLCWe also offer help and programming solutions for Siemens and Triconex PLCs, standby solutions for the PLS80E process control system and repairs around the PLS80E hardware. This also includes the repair of Cluster IO modules.