MICRA srl

PRECISION IN ALL WE DO. MICRA’s 50 employees perform a variety of precise turning, milling and grinding operations.

Kontakt

MICRA srl

via Armentaressa,16

34076 Romans d'Isonzo, Italy

-

Show phone number

+39 0481 909592

- Show Email

- www.micrasrl.it

Contact Person

- Gabriele Fanna

-

Show phone number

+39 0481 909592

- Show Email

AHK Italy

Mrs. Barbara Maldari

Phone:

+39 02 39800931 / +39 340 9624147 [email protected]

Profile

Galerie

PRECISION IN ALL WE DO

Since 1991 we have been committed to achieving excellence in the field of precision mechanics. Innovative processes and advanced technologies are our tools. Maximum quality, punctuality and competitiveness are the cornerstones of our work.

MICRA’s 50 employees perform a variety of precise turning, milling and grinding operations.

Heat treatment and coating operations are undertaken by a quality-audited associate company.

Business

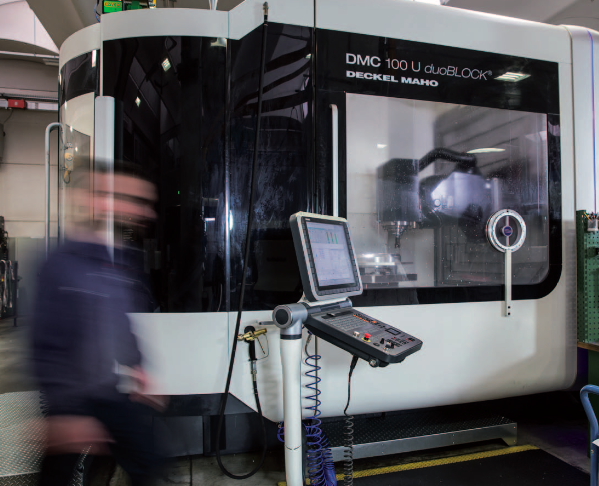

We constantly update and expand our range of machines with the most advanced technologies in order to meet the increasingly complex requirements of our clients. Alongside our 5-axis machining centres and other machine tools, we have a CMM measuring machine and a presetting CNC that enable us to provide our European customers with an increasingly comprehensive and high-quality range of solutions.

Market leading companies in various innovative sectors have chosen Micra as their supplier of choice for their machines, often requiring complex and quality-certified operations. Thanks to the precision and quality it puts into every detail, Micra has become a key supplier for many major businesses all over Europe.

Over the years Micra has acquired great experience in the production of precision mechanical parts for the energy sector, securing contracts in the hydroelectric, oil&gas and nuclear fields. Working in these sectors has honed our ability to expertly manage any specific client request, from the traceability of materials to destructive and nondestructive tests.

For many years Micra has worked alongside companies specialising in the pressing of aluminium items, supplying inserts that require high levels of precision and resistance. The experience and knowhow acquired in this sector enables us to provide our clients with a perfectly tested product, even after the various thermal treatments requested.

Video

Products/Services/Offers

Products/Services

5 AXIS MILLING

Five-axis machining: able to machine complex shapes in a single set-up. Micra has extensive CNC machining experience and has been providing CNC machining services to customers all over the world. During the last 29 years, Micra keeps updating our production process and our equipment in order to provide supreme service and top quality products to our customers. Ordering high quality machined parts is no longer a challenge if choose to work with us. Quality control equipment, including 2 CMM, height gauges, surface & hardness testers, and gauges. Compliance to exact customer specifications. 5 CNC turning centers plus 3 & 5 axis CNC milling machines to meet your custom precision machining requirements. Value-added services such as polishing, anodizing, extrapolating, heat treatment, welding, painting, assembling are also available. In-depth experience working with materials of all types 3- and 4-jaw chucks, in-house fixture and tooling give us precise control over cost and quality. Our 5 Axis Milling Machines: 5-axis G550 Universal MachiningCenter GROB 5-axis a500Z Horizontal Machining center Makino, 5-axis machining centre DECKEL-MAHO DMC 100U 5-axis machining centre DECKEL-MAHO DMU 70 eVolution 5-axis machining centre DECKEL-MAHO DMU 60P Materials: Aluminum Alloy Stainless Steel Carbon Steel Copper Brass Titanium

AEROSPACE

Our enthusiasm for the upcoming challenges is a guarantee of our 100% commitment to the task in hand. We are currently specializing in a new area, that of aerospace: our future will be one of new investment, wholehearted commitment, and important EN 9100 certification in 2013. In this sector we have to process increasingly complex materials, such as titanium, and must be able to offer all types of thermal and surface treatments requested. To satisfy these requirements and provide a complete solution, we therefore work alongside partners that are certified in both Italy and overseas. More than ever before we can approach the market as a top-quality supplier for those that seek quality and experience. Micra has extensive CNC machining experience and has been providing CNC machining services to customers all over the world. During the last 29 years, Micra keeps updating our production process and our equipment in order to provide supreme service and top quality products to our customers. Ordering high quality machined parts is no longer a challenge if choose to work with us.

ASSEMBLING

Assembling: composing of manufactured components into a complete product. Micra has extensive CNC machining experience and has been providing CNC machining services to customers all over the world. During the last 29 years, Micra keeps updating our production process and our equipment in order to provide supreme service and top quality products to our customers. Ordering high quality machined parts is no longer a challenge if choose to work with us. Quality control equipment, including 2 CMM, height gauges, surface & hardness testers, and gauges. Compliance to exact customer specifications. CNC millturn plus 3 & 5 axis CNC milling machines to meet your custom precision machining requirements. Value-added services such as polishing, anodizing, extrapolating, heat treatment, welding, painting, assembling are also available. In-depth experience working with materials of all types. 3- and 4-jaw chucks, in-house fixture and tooling give us precise control over cost and quality. Materials: Aluminum Alloy Stainless Steel Carbon Steel Copper Brass Titanium

MILLTURN

MIllturn: highest stability and precision. Micra has extensive CNC machining experience and has been providing CNC machining services to customers all over the world. During the last 29 years, Micra keeps updating our production process and our equipment in order to provide supreme service and top quality products to our customers. Ordering high quality machined parts is no longer a challenge if choose to work with us. Quality control equipment, including 2 CMM, height gauges, surface & hardness testers, and gauges. Compliance to exact customer specifications. CNC millturn plus 3 & 5 axis CNC milling machines to meet your custom precision machining requirements. Value-added services such as polishing, anodizing, extrapolating, heat treatment, welding, painting, assembling are also available. In-depth experience working with materials of all types.