Costam Hi-Tech S.r.l.

Costam is leader in: - sheet metal pressing; - precision mechanical machining: milling and turning; - assembly of mechanical components; - surface finishings and treatments;

Kontakt

Costam Hi-Tech S.r.l.

Via Maniago, 8

33080 San Quirino (PN), PN

-

Show phone number

+39 0434 919495

- Show Email

- costam.it

Contact Person

- Luca Scian

-

Sales Manager

-

Show phone number

+39 348 2228211

- Show Email

AHK Italy

Mrs. Barbara Maldari

Phone: +39 02 39800931 / +39 340 9624147

maldari@ahk.it

Year of founding

1968Certifications

ISO 9001:2015

Profile

Galerie

Established in 1968, COSTAM is specialized in producing high-precision mechanical components with a high added value. Its production flexibility meets its clients’ demands, both for small batches and for large series.

In fifty years of activity, the company has developed proven expertise in different fields: automotive/truck, home appliances, textile machinery, industrial automation, electronic-industrial, agricultural machinery/garden equipment, energy, pneumatic, oleodynamic, industrial compressors, home automation, air conditioning and heating, design-furniture, typographic printing machines and professional cooking equipment.

Business

COSTAM combines processing of standard materials as well as of particular ones. Moreover, in the subcontracting of complex mechanical components, it provides its competitive advantage, that is the integration among different skills:

- Sheet metal pressing with mechanical presses from 15 to 500 tons.

- Precision mechanical machinings - milling - with horizontal and vertical machining centers.

- Design and construction of dies for punching, bending and deep-drawing operations, with progressive and shooting dies.

- Assembly of mechanical components.

- Client support in the design phase (co-design) to meet functional, dimensional and aesthetic requirements, optimizing, at the same time, materials, geometries and treatments, in an efficient production process.

- Surface finishings and treatments, thanks to a strong partnership with important and leading companies.

Since 1997, the certification of the quality management system has proved the company commitment to a continuous improvement of processes. Nowadays, its precision mechanical machinings with CNC machining centers meet the requirements of the UNI EN ISO 9001:2015 standard.

COSTAM continuously invests in specific technologies and in highly qualified personnel to offer its clients a highly reliable service European market-oriented.

Downloads

Video

Products/Services/Offers

Products/Services

INISHING AND SURFACE TREATMENTS

Supply of auxiliary processes, finishing and surface treatments OTHER PROCESSING To guarantee its clients’ specifications and requirements, COSTAM provides a series of additional processes, finishing and surface treatments, thanks to the collaboration with selected partners, thus integrating different skills in a complete production chain. In particular, it offers the following additional processes: grinding, lapping, laser cutting, punching, paneling, press-bending, welding, satin finishing, micro-shot peening, tumbling, serigraphy and pad printing. The finishing and the thick chromium-plating treatments, chemical nickel-plating, Ruveco ® lead leaching process, T.E.A. ® coating and DurAll ® aluminum passivation are made by Alfatech s.r.l., a Querinuzzi family company. Other finishings and treatments that COSTAM makes available for its clients are: painting, galvanizing, burnishing, manganese phosphating, trivalent chromium-plating, brightening, electrolytic nickel plating, gold plating, cataphoresis, anodization, carbonitriding, hardening, cementation, drainage, annealing, stabilization, distension and nitriding. NETWORKING Collaboration, innovation and competence are our values that guarantee our main goal: the result. Thus, in 2013, driven by the continuous search for productive synergies, COSTAM - together with other well-known companies in Pordenone - established the Seed Group business network, synonymous with excellence and integration of skills in mechanical subcontracting. This is a union that is more than the sum of the individual parts: a team able to manage complex project flows, from design to realization, on an international level. Seed Group uses the know-how merger, as a basis, and the typical flexibility of small and medium-sized companies, as a competitive potential.

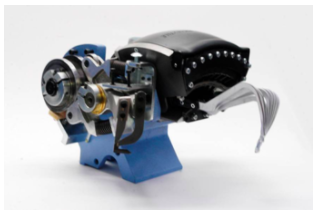

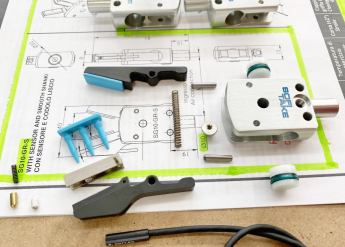

MECHANIC ASSEMBLY

Supply of Complex and High Standard Assembly Service of Mechanical Components MECHANIC ASSEMBLY At the end of a complete production and logistic cycle, in addition to the control of the aesthetic and functional requirements, the washing and removal of processing residues, COSTAM offers an assembly service of mechanical components according to the bills of materials and client’s requirements. In assembly operations, the complexity and high standards of the finishings of the groups assembled require cleaning, accuracy and use of specific equipment.

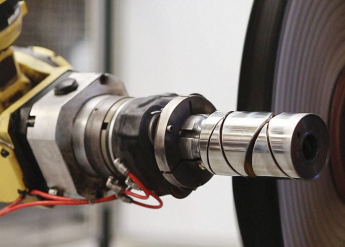

MILLING

Manufacture of High Precision Mechanical Components with CNC Vertical and Horizontal palletized machining centers and FMS. MILLING COSTAM manufactures high precision mechanical elements with modern CNC vertical and horizontal palletized machining centers. Moreover, it guarantees small and medium series flexible production thanks to a modern, fully automated flexible manufacturing plant FMS (Flexible Manufacturing System) - made up of 3 CNC machining centers connected by an automated warehouse and equipped with 48 pallet stations and 810 tools. Some cutting-edge CAD/CAM systems allow to manage production processes and make them more efficient with optimized and constant processing cycles. COSTAM works standard profiles, shaped profiles, castings, stamped components made of ferrous, non-ferrous, metallic and non-metallic materials. MECHANICAL MACHININGS EQUIPMENT Each project is carefully analyzed by COSTAM to define an optimized and efficient production cycle. In this phase, COSTAM offers its clients all its mechanical machinings experience to design and manufacture equipment and clamping systems to be used in machining operations. The state-of-the-art machine tools, the continuously updated CAD/CAM software and highly skilled technicians allow the production of reliable equipment, which guarantee high quality standard productions and, at the same time, offers maximum operating flexibility.

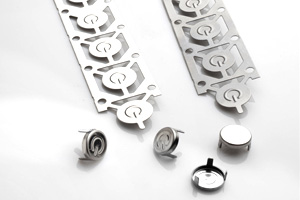

SHEET METAL PRESSING

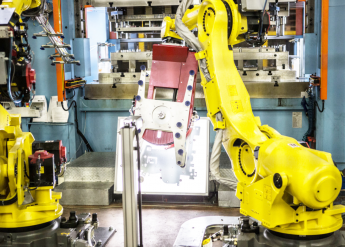

Flexible and Efficient Production of High Quality Sheet Metal Components With Mechanical Presses Fully Asserved. SHEET METAL PRESSING COSTAM pressing department produces components from sheet metal or strips with mechanical presses from 15 to 500 tons at controlled speed, stroke and positioning. It guarantees large series production, meeting high quality standards thanks to automatic feeding lines and progressive dies, also equipped with automatic threading and carriers for the simultaneous execution of several operations. Furthermore, the robotic cells for components loading and unloading allow a flexible and efficient production, even for small and medium-sized series. COSTAM directly takes care of dies and equipment maintenance to guarantee a constant quality standard of production. COSTAM carries out processings both on mechanical components with reduced dimensional tolerances and on elements requiring a high aesthetic finish. Thanks to the co-presence of different skills within the company, it provides a complete service that meets its clients’ numerous needs. Furthermore, it uses some selected partners for complementary processing, surface treatments and finishes, thus integrating the processes carried out in-house. COSTAM processes metal sheet and strips, from 0.05 to 6 mm thick, in carbon steel, stainless steel, aluminum, copper and its alloys. DIES CONSTRUCTION After a careful analysis, COSTAM defines an optimized and efficient production cycle for each project, providing the clients with its experience in design and construction of progressive and shooting dies for punching, bending and forming of sheet metal components. Thanks to the experience of high skilled technicians and to the use of innovative materials and modern technologies in surface-treatments and coatings, the state-of-the-art machine tools and the continuously updated CAD/CAM softwares enable the realization of reliable equipments that ensure high-level quality productions even in the long term.