Radius Group

Radius is a manufacturing company with three business units that provide CNC turning & milling services, hydraulic tube & hose assemblies and hydraulic cylinders for the OEM sector.

Kontakt

Radius Group

Sära tee 8

75312 Peetri, Estonia

-

Show phone number

+372 5551 4060

- Show Email

- www.radius.ee

Contact Person

- Eva Laanemäe

-

Regional manager

-

Show phone number

+372 5551 4060

- Show Email

CEO / Chairman

Ahti TaltsVAT number

EE100956876Offices

In Tallinn, Tartu and Pärnu (Estonia)Year of founding

2005Certifications

ISO 9001

ISO 14001

Profile

Galerie

ABOUT US

Radius’ motto is to offer our clients only the best high-quality products and to keep our promise in manufacturing our products in an efficient manner.

Currently, over 40% of our product output is for export markets.

Radius has two basic business areas: mechanical CNC machining and hydraulics.

Furthermore, Radius Machining OÜ’s focus area of activity is subcontracting on modern CNC turning and milling machines, which ensures the high-quality production of parts in serial manufacturing.

The main area of activity for Radius Hydraulics is the production of hydraulic hose and pipe sets, along with other varying components on offer.

We know that our greatest asset are our employees. Long-term employment and lifelong learning have given our employees the motivation and security to grow with us and reach their personal and professional highs.

This mindset has given Radius the opportunity to take on challenging new projects that require highly skilled people at all levels of our company.

Business

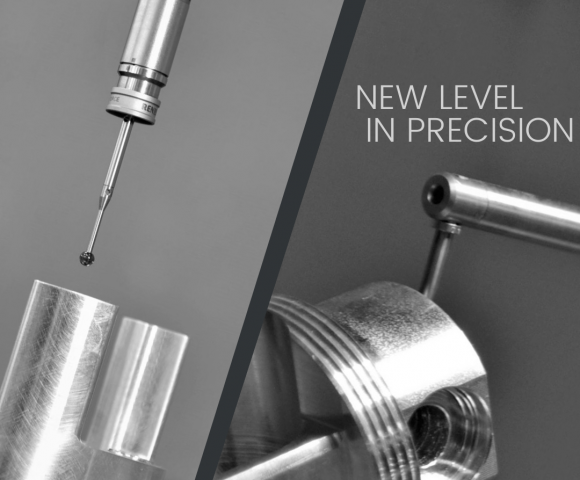

CNC MACHINING

Radius Machining's core business is serial CNC turning and CNC milling. A modern fleet of CNC machines enables the efficient production of both simple and more complex parts.

CNC TURNING

In total, Radius Machining has 12 lathe machines of varying power and complexity, of which 4 are automated machine tools that can produce large series in a short amount of time. The CNC lathes are equipped with active tools that allow complex components to be produced using one machine. Delivery time is also reduced through the work centres’ automated feedstock.

Radius Machining has also taken great stride in the technology sector. In particular, an industrial robot with a lifting capacity of 90kg has begun loading and unloading components from the highest-capacity tool machine. As a result of the 25kg limit removed, the work process becomes smoother and there is no delay in feeding. In the future, the robot will be able to do the work of several shifts independently with the prerequisite of large series. An example of this case is presented with automotive and agricultural equipment manufacturers.

CNC MILLING

One of the company’s main business areas has been CNC milling.

Radius Machining advises clients from the idea phase to the creation of the model and the manufacturing programme, component production, and delivery.

In addition to our software expertise, Radius has the advantage of serial production and the availability of a range of sophisticated machine tools. This allows the quick production of both simple and more complex components. The automated feeding of raw materials also helps to save production time.

ASSEMBLY

Radius has also taken on product assembly. Components are assembled on-site and the necessary markings are made, such as the engraving of serial numbers. Packaging follows testing; thereafter the finished product is delivered to the client in a timely manner.

When it comes to the assembling of products we are flexible. We can put together the requisite components from our own product range or we can order the required parts from another manufacturer. If necessary, we can also help with drafting work drawings.

Thus, Radius takes on the entire project management process from the production or ordering of the necessary components to the assembly and transport of components, while saving the client a significant amount of time and money.

HYDRAULICS

Radius Hydraulics OÜ has been established to offer our customers technical support in the field of hydraulics and pneumatics, we are able to offer variety of development solutions and products according to the customer's wishes-The main product groups are sets of hydraulic hoses and pipes with various hydraulic components. The CNC pipe bending machine allows the production of precise parts in series

HYDRAULIC HOSES

Radius Hydraulics manufactures high-quality hoses and hose assemblies, offering comprehensive assistance in selecting the right hose type, nozzles, and transitions.We use a modern Finnpower machine tool that allows us to press hoses with a diameter of up to 2”.

HYDRAULIC PIPES

Radius Hydraulics uses the Herber CNC pipe press machine tool to produce high-precision parts in series. Our main client for hydraulic pipe sets is the engineering industry but we also work with companies in other sectors. We can bend steel, including stainless steel and other materials with dimensions of 6 mm to 38 mm. In addition to pipes, we also offer the necessary pipe transitions in steel and stainless steel.

HYDRAULIC COMPONENTS

Radius Hydraulics produces a variety of hose and pipes sets for which we can also offer a wide range of other components. Our products are shipped both within Estonia and abroad; with our main export markets being Finland, Sweden, and Austria.

HYDRAULIC CYLINDERS

Radius Group's affiliate Radius Linder OÜ offers the production of hydraulic cylinders according to the customer's specifications or according to the customer's drawings. We manufacture hydraulic cylinders from black steel as well as stainless steel.

Video

Introduction Radius Machining

Products/Services/Offers

Products/Services

HYDRAULICS

HYDRAULICSThe main product groups are sets of hydraulic hoses and pipes with various hydraulic components. The CNC pipe bending machine allows the production of precise parts in series

Offers

Assembly

To reduce the costs of process management to our clients, 6 workstations help them in our assembly.For the customers who wish to have delivered a complete system without losing time for logistics. We produce the ordered parts, build them into a whole and deliver them to You without long waiting periods.