ABF LT, UAB

ABF LT is one of the biggest aluminium die casting and metal processing companies in the Baltic states. Using Monitor ERP system & equipped with fully automated die casting cells, supported by CNC machining, surface treatment & assembling we can offer the whole service package in one place.

Kontakt

ABF LT, UAB

Energetiku g. 2,

LT-89306 Mazeikiai, Lithuania

-

Show phone number

+370 443 30694

- Show Email

- www.abflt.com

Contact Person

- Karolis Jacinavicius

-

Marketing manager

-

Show phone number

+37061440848

- Show Email

AHK Baltic States / Lithuania

Ms. Vilma Areskiene

Phone: +370 5 263 9116

[email protected]

CEO / Chairman

Aidas MikalauskasVAT number

LT100004498718Participation in Exhibitions

Hannover Messe, Elmia, MidestYear of founding

2009Certifications

Company has implemented ISO 9001: 2015 quality management system. Quality control is performed by engineers using a variety of certified measuring instruments and coordinate measuring machines (CMM).

Profile

Galerie

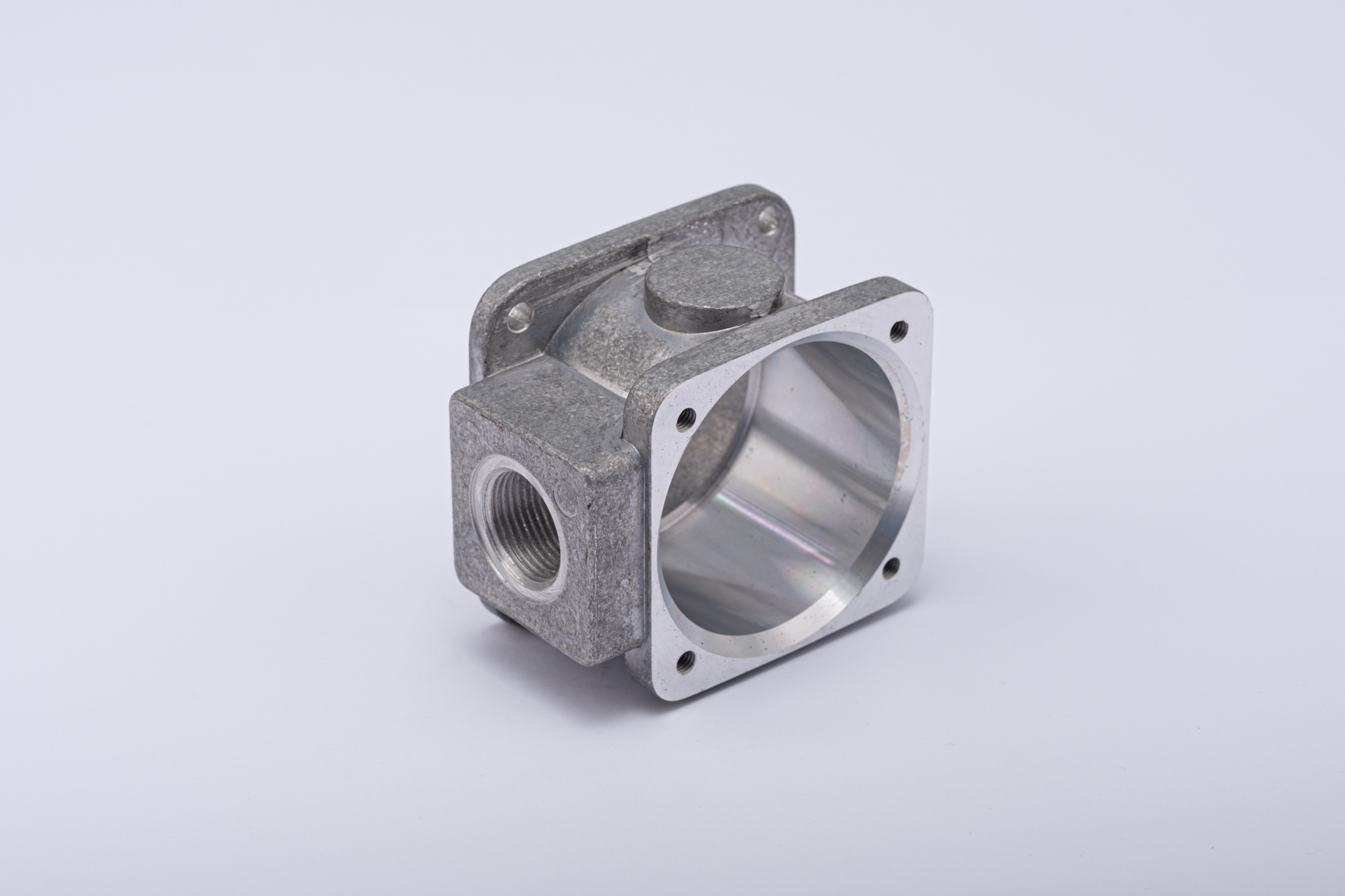

ABF LT is one of the biggest aluminium die casting and metal processing companies in the Baltic states. Using Monitor ERP system & equipped with fully automated die casting cells, supported by CNC machining, surface treatment & assembling we can offer the whole service package in one place.

We use automatic die casting machines with a closing force of 350 to 1000 tons. The maximum weight of the workpiece is 15 kg. We carry out CNC machining with YCM, HYUNDAI-KIA, NAKAMURA-TOME, EMCO TURN, HITACHI SEIKI, HAAS turning and milling centers.

Rotary transfer machines Riello Vertiflex and WITZIG & FRANK Twinflex gives us the edge of efficiently producing components in big batches at minimal cost.

Company has implemented ISO 9001: 2015 quality management system. Quality control is performed by engineers using a variety of certified measuring instruments and coordinate measuring machines (CMM).

ABF LT exports 95% of its production to customers in Germany, Scandinavia and the United Kingdom, operating in a variety of industries including railways, hydraulics, lighting, agriculture and forestry machinery, medical, shipbuilding and other markets.

Business

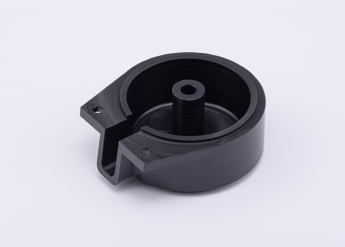

Aluminium die casting is one of the main processes of metal working.

It is accomplished by injecting molten aluminium into the mould under high pressure.

Moulds are first and foremost precision machined to give the final product shape.

This is the right choice for mass-produced products, since it is possible to produce very precise parts. In everyday life, we can see many products made during the die casting process.

Thanks to the use of automated die casting machines and robotic systems, we can anticipate work processes and produce very large volumes continuously. We guarantee our customers flexibility and quality of the produced castings.

We use automatic die casting machines with a closing force of 350 to 1000 tons. The maximum weight of the workpiece is 12 kg.

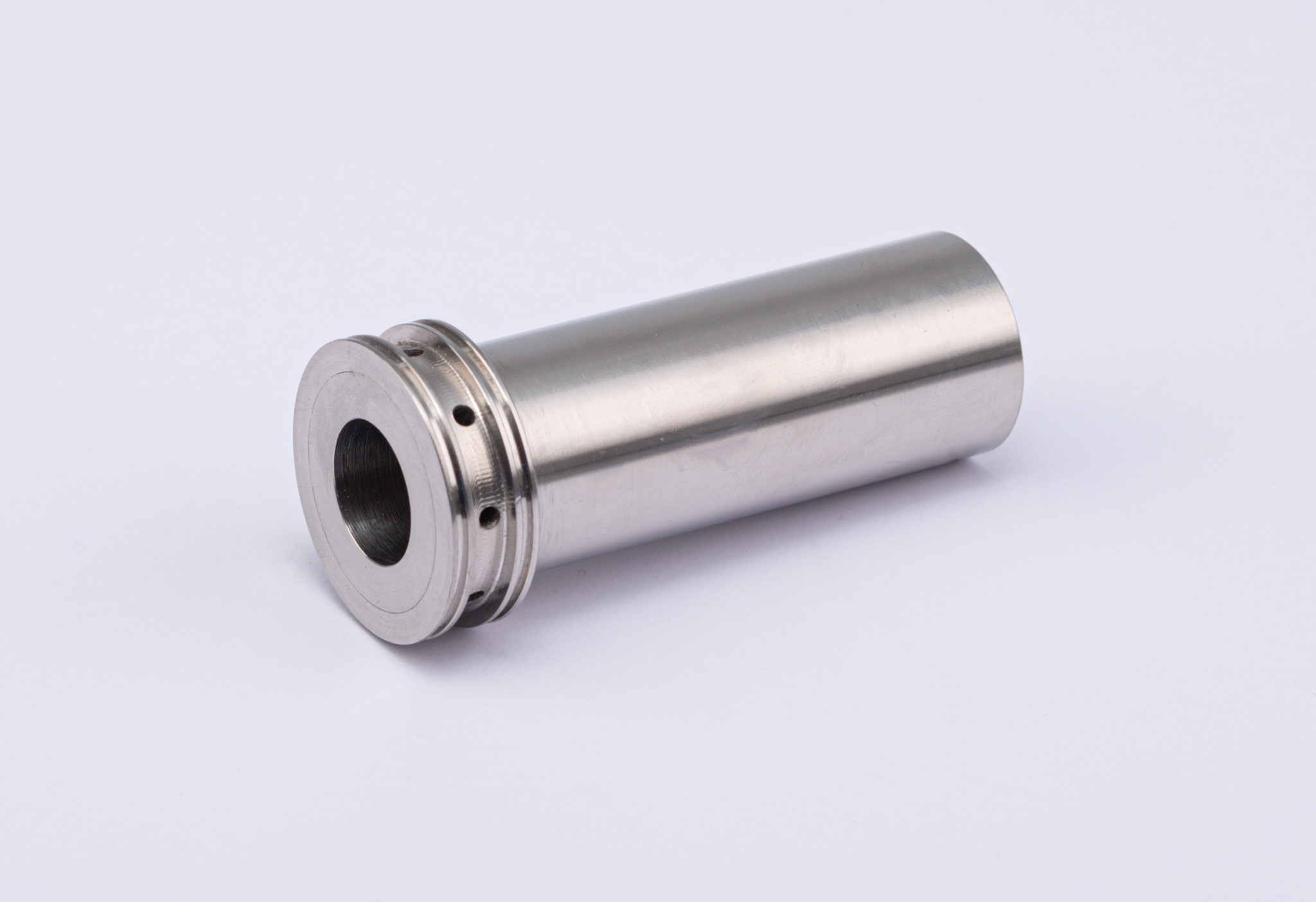

Turning

CNC lathes are used to produce parts from bars when the cutting tool moves linearly and the workpiece rotates. During the turning process, materials such as metal or plastic are rotated by computer numerical control. CNC turning can be done outside or inside the workpiece to produce tubular components of various geometries.

Milling

CNC milling is a machining process that uses computer controls and rotating multi-point cutting tools to gradually remove material from the workpiece and produce a custom-made part according to the drawing. CNC milling uses horizontal or vertical milling machines, depending on the milling specifications and requirements.

We carry out CNC machining with YCM, HYUNDAI-KIA, NAKAMURA-TOME, EMCO TURN, HITACHI SEIKI, MORI SEIKI, HAAS turning and milling centres.

Customers can be sure that turning and milling operations will be produced in a professional and timely manner. CNC turning and milling is also greatly influenced by the qualifications and experience of the staff. At ABF LT these works are performed by highly qualified specialists who have vast work experience in the processing of the most complex products.

ABF LT has a wide range of technological capabilities and is flexible in the field of metalworking and can therefore meet the ever changing needs of our customers.

We provide metal grinding, welding, hardening, sanding, engraving and other works.

Industry Focus

Values and export markets:

Competence and experience. Modern thinking. Sharing responsibilities. Achieving results and being open to innovation and teamwork. These are ABF LT's most important values.

ABF LT exports 80% of its production to customers in Germany, Scandinavia and the UK, operating in a wide range of industries, including railways, hydraulics, lighting, agricultural and forestry machinery, medical, shipbuilding and other markets.

Video

Products/Services/Offers

Offers

Aluminum die casting

Die casting cells with closing force 350-850t. Maximum weight of the workpiece - 12kg, projection of 1Die casting cells with closing force 350-850t. Maximum weight of the workpiece - 12kg, projection of 1

CNC turning & milling

CNC machining is carried out by YCM, HYUNDAI-KIA, NAKAMURA-TOME, EMCO TURN, HITACHI SEIKI, HAAS turning & milling centres.CNC machining is carried out by YCM, HYUNDAI-KIA, NAKAMURA-TOME, EMCO TURN, HITACHI SEIKI, HAAS turning & milling centres.