Rubate Metal LTD

Main business activity is metalworking (subcontracting), production of different steel products. We offer certificated manufacturing process with stable lead-time and quality.

Kontakt

Rubate Metal LTD

Baložu street 4

LV-4401 Gulbene, Latvia

-

Show phone number

+37126367668

- Show Email

- rubatemetal.lv

Contact Person

- Edijs Augulis

-

Production manager

-

Show phone number

+37126367668

- Show Email

AHK Baltic States / Latvia

Mrs. Solveiga Abolina

Phone: +371 67 32 1313

[email protected]

CEO / Chairman

Edijs AugulisVAT number

LV44103039066Year of founding

2006Certifications

EN 13769:2003

EN ISO 10961:2012(2019)

EN 1090-1,2(EXC3)

EN ISO 3834-2

ISO 9001:2008

AQAP- 2120:2009

ISO 9001:2015

ISO 14001:2015

LVS OHSAS 18001:2007

ISO 9606

Profile

Galerie

The limited liability company "Rubate Metal" was established in 2006. The main activity of the company is metal processing - production of metal products. The company provides its existing and future customers with a wide range of services related to metal processing, including processing of customers' drawings, machining, sawing,

Over time, the company has purposefully developed, the production facilities have been expanded, modern technological equipment has been purchased and the number of employees in production has increased. The main sales market of SIA "Rubate Metal" is Norway , Great Britain, Germany, Belgium, Sweden, Finland, France, USA, Lithuania, Estonia, Latvia.

Business

Rubate metal’s main business activity is metalworking (subcontracting), production of different metal products – containers for transport, storage, incl. gas cylinders, material-handling equipment for the construction industry, spare parts for agricultural, forestry and construction machinery and bespoke assemblies from steel and stainless steel in accordance with customers’ technical information.

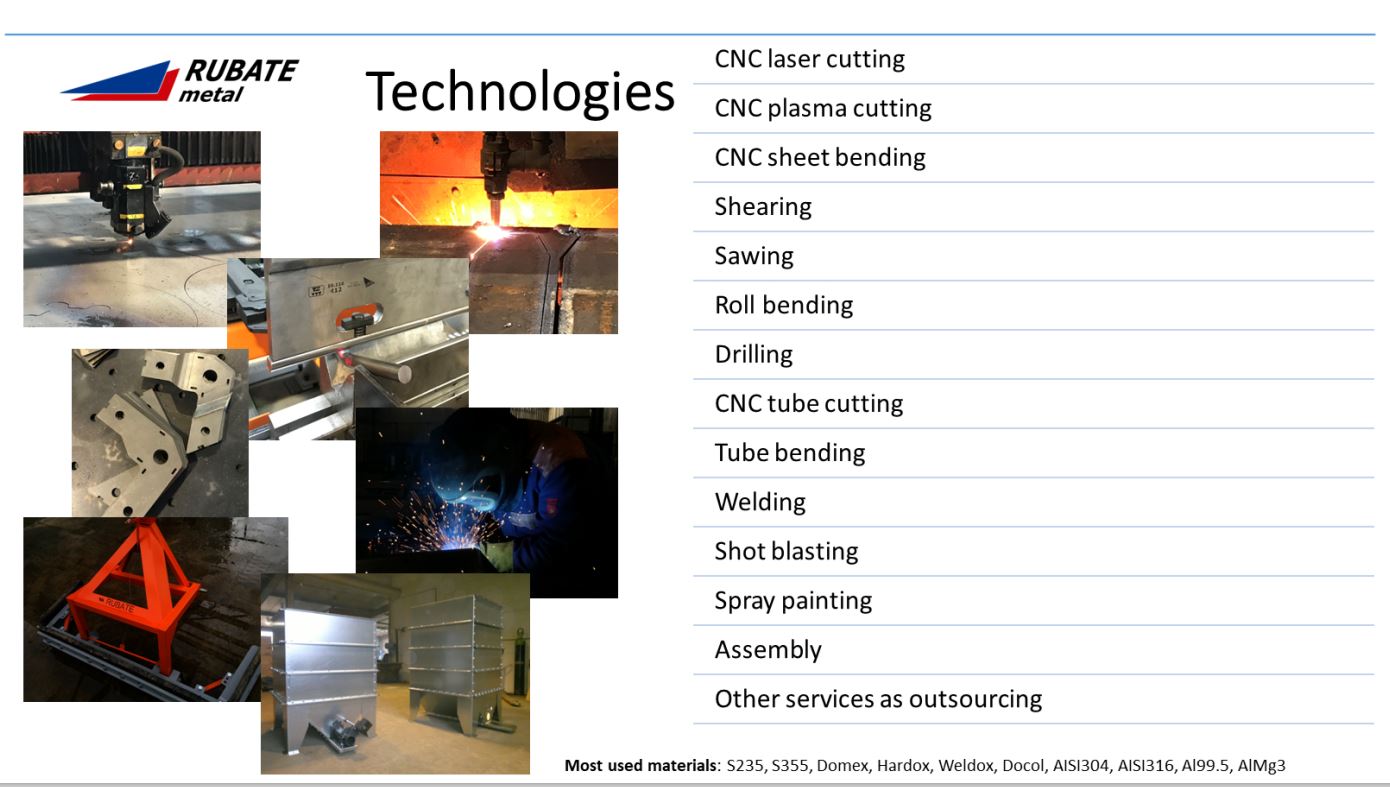

Technology

Sheet metal cutting with CNC laser cutting machine

Maximum sheet thickness for black steel 15 mm, stainless steel 8 mm, aluminium 5 mm. Maximum sheet size is 3000 x 1500 mm

Guillotine sheet cutting

Only for ferrous metals. Maximum cutting width 3000 mm, maximum cutting thickness 6 mm.

Sawing of profiled materials

With a band saw Maximum cross-section size 200 x 150 mm. Cutting range from 90 ° to 30 °.

Bending of sheet metal with CNC press

Working width of the press 4000 mm, bending capacity 2500 kN.

Sheet metal rolling

Maximum working width 1200 mm, maximum material thickness 6 mm.

Tube bending

Maximum tube diameter 40mm.

Drilling

Maximum drill diameter 80mm.

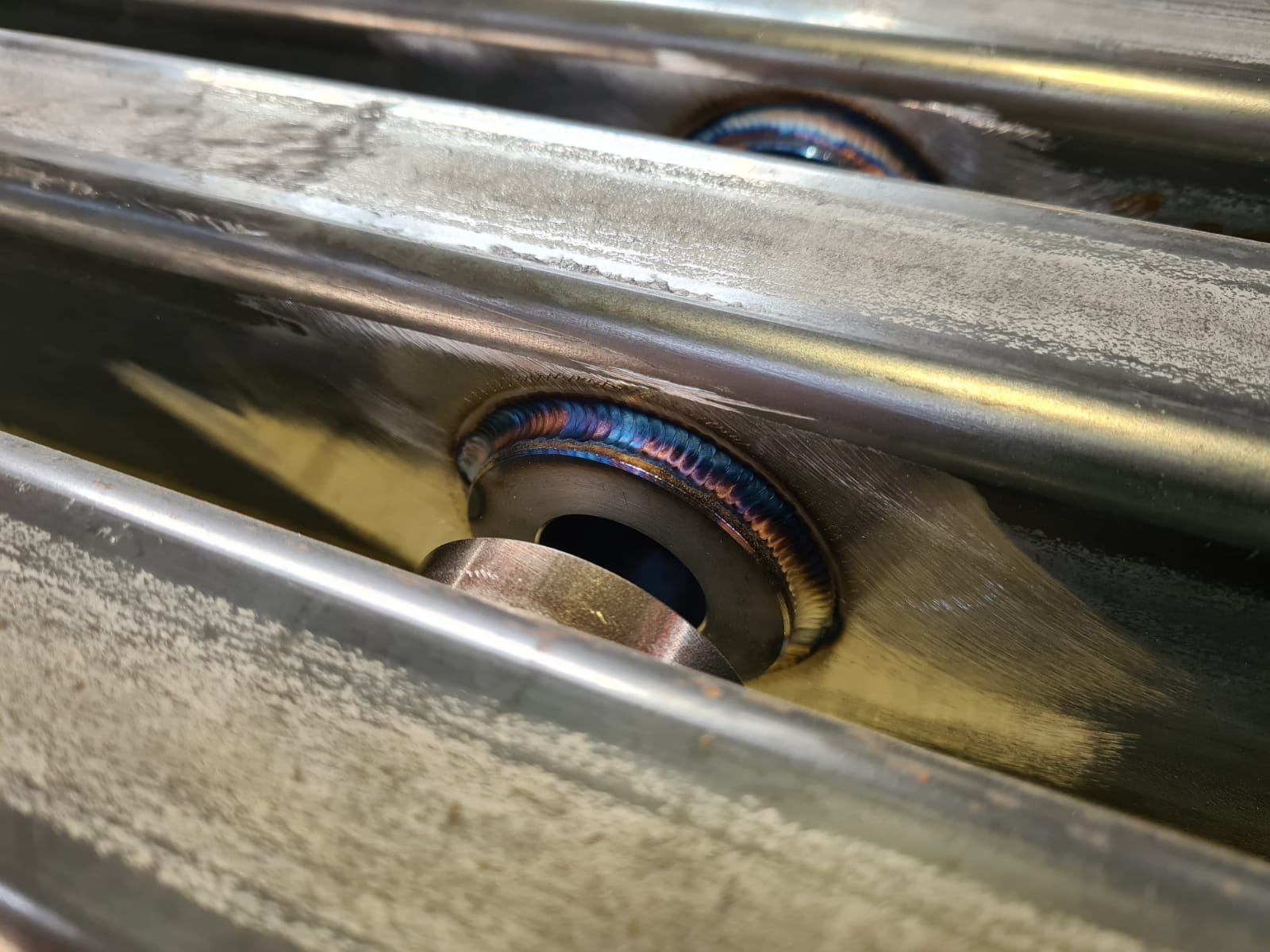

Welding

MIG / MAG welding, maximum material thickness for ferrous metal 30mm, stainless steel 8mm. All welders are certified according to LVS EN JSO 9606-1: 2018.

Surface treatment

A wet paint chamber is installed in the factory. The company also offers surface blasting.

Assembly

According to the customer's order, the products are fully assembled (the necessary additional elements are added).

Outsourcing

SIA "Rubate Metal" has a stable circle of cooperation partners in the following areas:

- Sandblasting;

- Powder coating;

- Hot-dip galvanising and electro-galvanising;

- milling, turning;

- plasma cutting.

Downloads

Video

Products/Services/Offers

Offers

Services - Rubate Metal LTD

Sheet metal cutting with CNC laser cutting machine Maximum sheet thickness for black steel 15 mm, stainless steel 8 mm, aluminium 5 mm. Maximum sheet size is 3000 x 1500 mm Guillotine sheet cuttingOnly for ferrous metals. Maximum cutting width 3000 mm, maximum cutting thickness 6 mm. Sawing of profiled materialsWith a band saw Maximum cross-section size 200 x 150 mm. Cutting range from 90 ° to 30 °. Bending of sheet metal with CNC pressWorking width of the press 4000 mm, bending capacity 2500 kN. Sheet metal rollingMaximum working width 1200 mm, maximum material thickness 6 mm. Tube bendingMaximum tube diameter 40mm. DrillingMaximum drill diameter 80mm. WeldingMIG / MAG welding, maximum material thickness for ferrous metal 30mm, stainless steel 8mm. All welders are certified according to LVS EN JSO 9606-1: 2018. Surface treatmentA wet paint chamber is installed in the factory. The company also offers surface blasting. AssemblyAccording to the customer's order, the products are fully assembled (the necessary additional elements are added). OutsourcingSIA "Rubate Metal" has a stable circle of cooperation partners in the following areas: Sandblasting; Powder coating; Hot-dip galvanising and electro-galvanising; milling, turning; plasma cutting.

Catalogs/Brochures

Rubate Metal - What we can offer

What we can achieve in our factory and with our outsourced partnersWhat we can achieve in our factory and with our outsourced partners