Jasil

JASIL is a metal mechanics company with a very dynamic approach and a culture of continuous improvement. It covers a large variety of processes that allows a big flexibility to the customers, allowing ordering a finished product to a single supplier.

Kontakt

Jasil

Parque Industrial de Adaúfe Lote I-6 Apartado 2032

4701-853 Braga, Portugal

-

Show phone number

+351 253 307 380

- Show Email

- www.jasil.com

Contact Person

- João Teixeira

-

Marketing & Customer Service Assistant

-

Show phone number

+351 253 307 380

- Show Email

Luís Oliveira (General Maganer) - [email protected]

Carla Costa (Comercial) - [email protected]

Renato Vale (R&D Manager) - [email protected]

CEO / Chairman

Luís OliveiraTurnover

5.00MVAT number

500738270Participation in Exhibitions

Midest - Subcontracting Industry | Eurobike - Bicycle industry | Eicma - Motorcycle industryYear of founding

1948Certifications

JASIL quality system is certified by ISO 9001 since 2010 and it is currently implementing IATF requirements.

Recognized by the Kaizen Institute in 2017 with an award “Excellence in productivity.

JASIL also promotes team work, so there is a constant investment in resources and new technologies in order to improve working conditions. It provides opportunities, develops leaders and recognizes talents.

Profile

Galerie

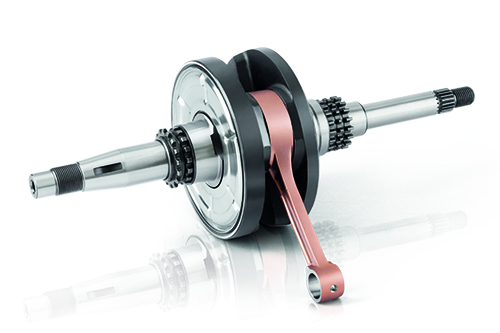

JASIL is a metalworking company whose principal activity is the manufacture of parts and accessories for motorcycles and scooters. Despite its 70 years of existence, is still a modern company, fruit of its permanent investment in new technologies.

The development of new products, the bet on quality and customer focus are the tools with what the future and new challenges are projected.

Business

The internal production processes that JASIL has are: FORGING, TURNING, MACHINING, GRINDING, GEAR MILLING, POLISHING, ASSEMBLING and PACKAGING.

JASIL also invest on ROBOTIZATION to optimise productivity and quality. JASIL is able to work on various raw materials such as aluminium, steel, brass, titanium and plastic.

The quality is ensured on supplier’s selection, with the guarantee of certified raw materials, always searching for the most advanced techniques of heat treatment, surface treatment, and the best logistics.

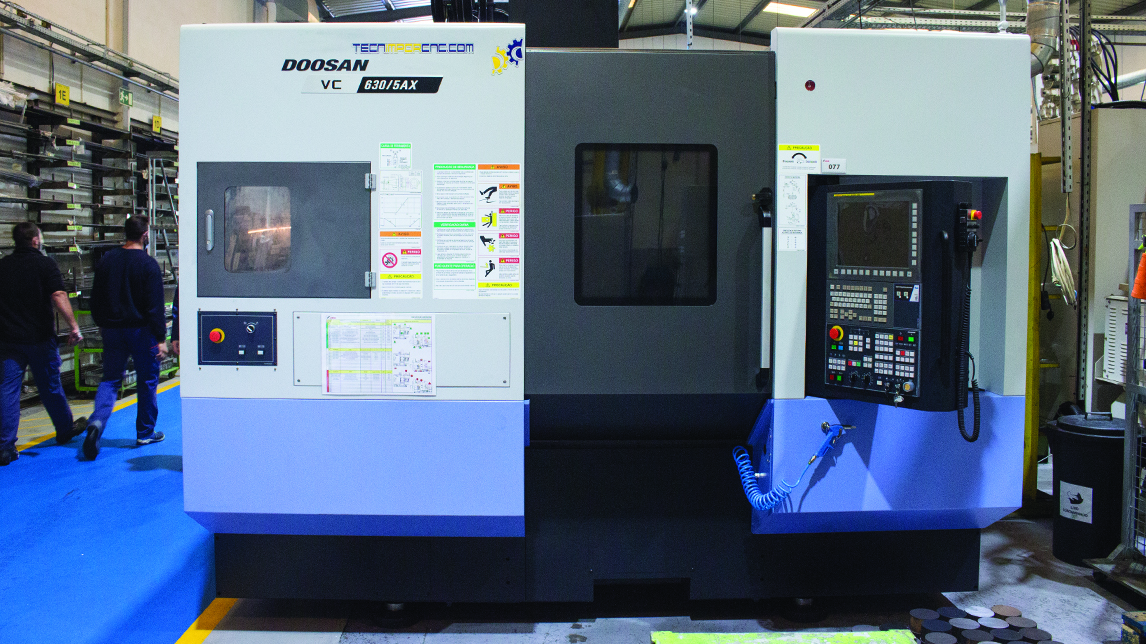

Strict quality control is also guaranteed throughout the manufacturing process. All CNC machines are connected to our ERP software allowing management team control production and quality. Control measurements are done on auto control following software instructions and restrictions.

Each measurement on each operation is stored on our server, allowing later follow up about whom, how and when it has been made.

Constant innovation is leading JASIL to apply solutions according to Industry 4.0 concepts. Kaizen lean methodologies started to be implemented in 2015 and achieved very significant improvements, recognized by the Kaizen Institute in 2017 with an award “Excellence in productivity.

The "Zero Defects" and "Six Sigma" are also concepts implemented on JASIL which helps to focus on quality, increasing productivity and reduce waste.

JASIL quality system is certified by ISO 9001 since 2010 and is currently implementing IATF requirements.

Downloads

Video

JASIL works for various business areas such as Bicycles, Karts, Microcars, Motorcycles, Paramotors and Construction Industry. It has an own brand and catalogue for engine parts and accessories for motorcycles and scooters.

The company is now preparing its own catalogue of bicycle components such as crank shafts, bottom brackets, sprockets, bike stems and seat posts.

JASIL is also producing parts for other sectors under customer request.

Products/Services/Offers

Products/Services

FORGING

JASIL has capacity for hot forging and cold forging, on steel, aluminum and brass. Available machines are: 4 friction machines up to 500 tons force, 4 mechanic machines up to 250 tones force and 1 hydraulic machine that allows 3D forging on aluminum.

GEAR MILLING

Straight-teeth or helicoidal-teeth gears can be produced up to module 3. The equipment available enables the grinding of gearing by the shaving process.

MACHINING & TURNING

JASIL has machining centers with 3, 4 or 5 axis, with or without a pallet and CNC lathes with manual or automatic bar feeder with up to 8 working axis that cover any machining operation. JASIL has highly productive Turning Machines equipped with two opposing spindles and twin turrets. The turning centers are a multi-task mill/turn center and are designed for heavy and interrupted cutting, long-term high accuracy and superior surface finishes.

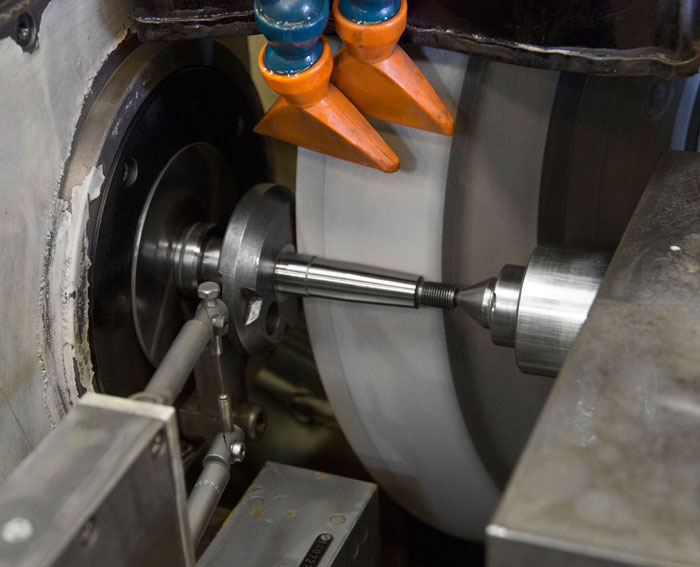

GRINDING

Grinding is a very important operation when very low tolerances and roughness are required. Our grinding processes are: Cylindrical and Conic Grinding, Inner Holes Grinding and Flat Grinding.