Offers

Scandicast

Iron CastingsScandicast casts all standard material qualities in grey cast iron and ductile iron. ON request we produce modified special iron grades. At this moment in our portfolio are 32 different specifications.

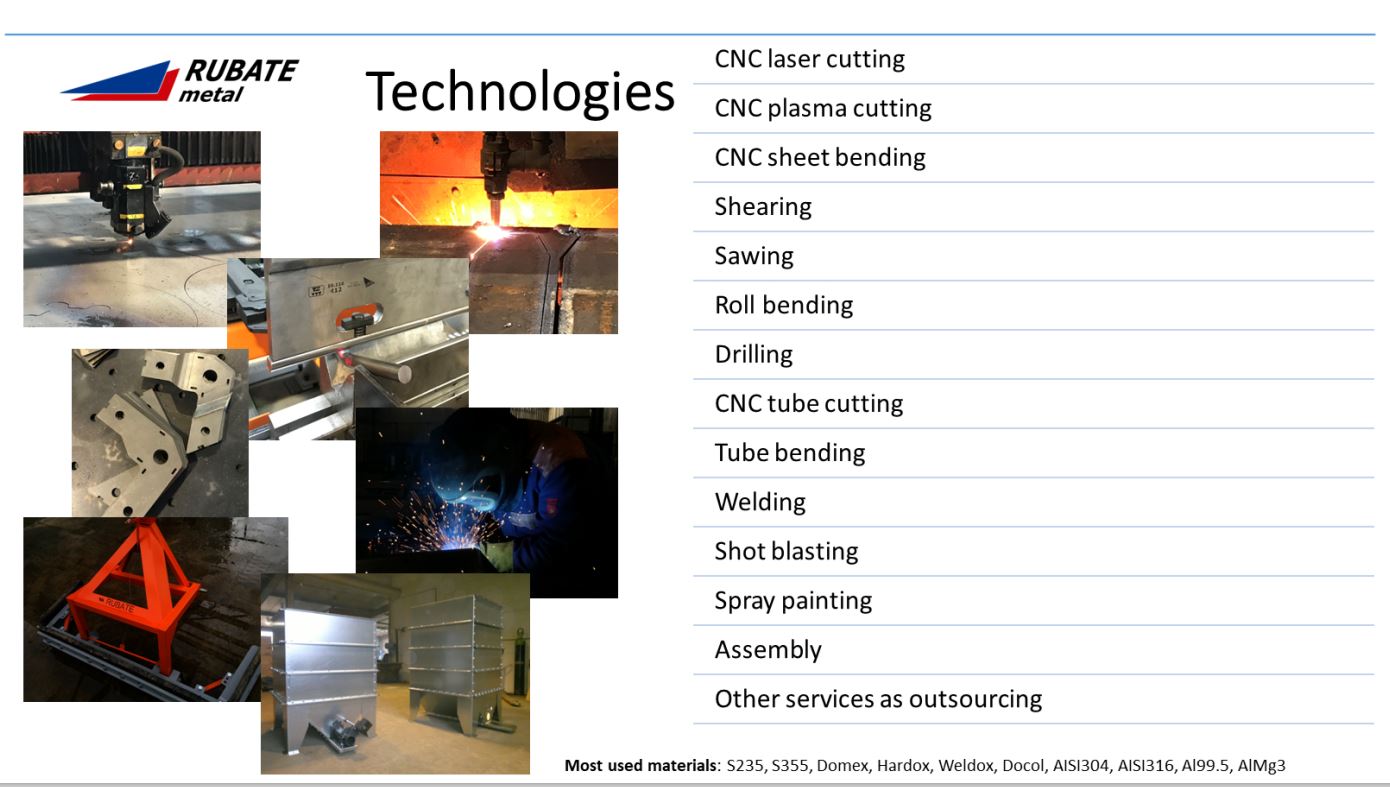

Rubate Metal LTD

Sheet metal cutting with CNC laser cutting machine Maximum sheet thickness for black steel 15 mm, stainless steel 8 mm, aluminium 5 mm. Maximum sheet size is 3000 x 1500 mm Guillotine sheet cuttingOnly for ferrous metals. Maximum cutting width 3000 mm, maximum cutting thickness 6 mm. Sawing of profiled materialsWith a band saw Maximum cross-section size 200 x 150 mm. Cutting range from 90 ° to 30 °. Bending of sheet metal with CNC pressWorking width of the press 4000 mm, bending capacity 2500 kN. Sheet metal rollingMaximum working width 1200 mm, maximum material thickness 6 mm. Tube bendingMaximum tube diameter 40mm. DrillingMaximum drill diameter 80mm. WeldingMIG / MAG welding, maximum material thickness for ferrous metal 30mm, stainless steel 8mm. All welders are certified according to LVS EN JSO 9606-1: 2018. Surface treatmentA wet paint chamber is installed in the factory. The company also offers surface blasting. AssemblyAccording to the customer's order, the products are fully assembled (the necessary additional elements are added). OutsourcingSIA "Rubate Metal" has a stable circle of cooperation partners in the following areas: Sandblasting; Powder coating; Hot-dip galvanising and electro-galvanising; milling, turning; plasma cutting.

Exigum

Mechanical system assemblingDifferent part group assembling including Elements: bearings, gaskets, sheet metal parts, etc.;Assembly dimensional, pressure, etc. testing according to the client request

EMJ Metals SIA

PRODUCT DESCRIPTION Touch free hand disinfection device allows you to disinfect your hands, thus improving hygiene standards in public places. Just highlight the words you want to design and choose from the various options in the text editing bar. It is possible to make ground fasteners for outdoor use of the device. The device is designed, produced and assembed in Latvia. When ordering in larger amounts it is possible to adjust or change the design, make a laser engravings or cut-outs (logos, names, etc.), as well as cover the device with sticker of customer's design.

PROMEL SRL

PROMEL® Engineering Services PROMEL was originally and engineering company and since its foundation it has tried to boost this department by providing its own engineers with adequate project platforms and thus provide a complete service to its customers: from basic to detail engineering, from the research and development phase to industrial design. The engineering department operates in different sectors: mechanical, electronic, electro-instrumental design, control and monitoring systems.Technical plants engineering was added to that with the support of a company working since long time in the petrochemical, power generation, waste-to-energy plants and sewage purification. Our competences and the available instrumentation enable us to cover a great range of services.

NERI LABELS SRL

ELF-ADHESIVE LABELS ManufacturingSelf-adhesive labels in paper or film produced in rolls and / or sheets with flexographic, serigraphic, digital and hot prints. Multilayer labels, booklets, coupon labels, holograms, labels with RFID, scent labels and security technologies, any idea can be developed and realized. Our products don’t fear challenges, they were born to serve markets with strict standards, pharmaceuticals, food and cosmetics.

C.E.L. S.p.A.

Plastic Moulding Conventional plastic mouldingConventional molding is used in the case of molding of single-component plastics.Always up-to-date, it allows the realization of medium and small thickness artefacts. Traditional molding allows the production of objects with or without metal inserts, with customizable finishes.Overmolding of metal insertsThe CO-MOLDING allows the production of finished products made of different types of material together. A process that guarantees the highest quality and an excellent aesthetic result.The efficiency of our latest generation presses allows us to mold together plastics and metal parts, with this process we manufacture products like valves, knobs or gears.The result is fast processing, which reduces production costs and optimizes production times, in oder to meet the needs of our customers.Two-component injection molding The two component-injection molding allows two different plastic materials to be used simultaneously inside the mold.The production of objects follows well-defined sequences to guarantee an optimized yield of the finished product.The manufacturing process is simultaneous, which speeds up production while keeping costs down.Molding with Gas injection technology (GIT)Assisted gas molding is suitable for the processing of products of any thickness and complex design.In addition to the shape, in fact, this technology can make different sections even within the same component, thus achieving peculiar design forms.Metal replacementReplacing metal alloys with high-performance technopolymers finds endless fields of application: from the automotive industry to thermo-hydraulics, from electronics to mechanics to the food sector, this method allows to improve the aesthetics of the product reducing costs, without diminishing the structural characteristics of the parts produced.IML MoldingThe innovative IML system (in moldlabelling) is a printing process that allows you to customize the product during the injection process by applying the decoration inside the mold. Particularly suitable for all products that require quality printing with high resolution graphics or images, as in the case of food packaging.The print can be made all-over, completely covering sides of the container for an alluring result.

C.E.L. S.p.A.

Recycling State-of-the-art workmanship to ensure a compliant, long-lasting product that combines aesthetic beauty with practical functionality.

C.E.L. S.p.A.

Heizung, Hydraulik, Kältetechnik, Wasseraufbereitung Wir sind auf Formen von Kunststoffen spezialisiert in Bereiche wie Hydraulik, Kältetechnik und Luftaufbereitung. Eine breite Produktvielfalt, die verschiedene Spritzgusstechniken kombiniert, um das beste Produkt zum besten Preis anzubieten.