Offers

Flama

Industrial Capacity Thermoplastic injectionFLAMA has developed a solid experience and high know-how on thermoplastic (plastic parts) and thermoset (bakelite) production. All its processes – from production to delivery – meet high quality criteria. Manufacture of Moulds and ToolsFLAMA benefits from great experience in the manufacture of tools and moulds for plastic injection in several fields such as fast-moving consumer goods, the auto industry, and electrical and sanitary equipment. PrintingFLAMA produces a great variety of metal components for all different applications. It is capable of transforming many types of raw material, particularly stainless steel. WeldingIn the metal field, experienced teams carry out safe welding operations. PolishingFLAMA has equipment for sanding and polishing metal parts in order to obtain a matte or gloss finish. PaintingThe different painting techniques used by FLAMA allow for a highly-quality end result. Powder coating is used to decorate different metal parts. The non-stick treatment is obtained by means of the painting process. Surface treatmentBefore the metal parts are painted, they go through a chemical or mechanical stripping process. AssemblyQualified teams work flexibly and in shifts. Execution rigour and quality control carried out on every stage ensure a top quality end product. Pad Printing and SerigraphyFLAMA has equipment for marking plastic or metal parts in the case of a logo, pictogram, or symbol. The pad printing and serigraphy processes ensure a high-quality result in accordance with the specifications. Laser markingFLAMA counts on the most advanced equipment for laser marking metal parts.

SIRMAF

Standard and Machining Parts Sales THE CUSTOMER needs a very specific machine component or system, or needs a machined part. With SIRMAF Machine World knowledge we can provide a valuable support to find that specific component or system. With our CAD/CAM and machining skills we manufacture your parts.

Niho Motors d.o.o.

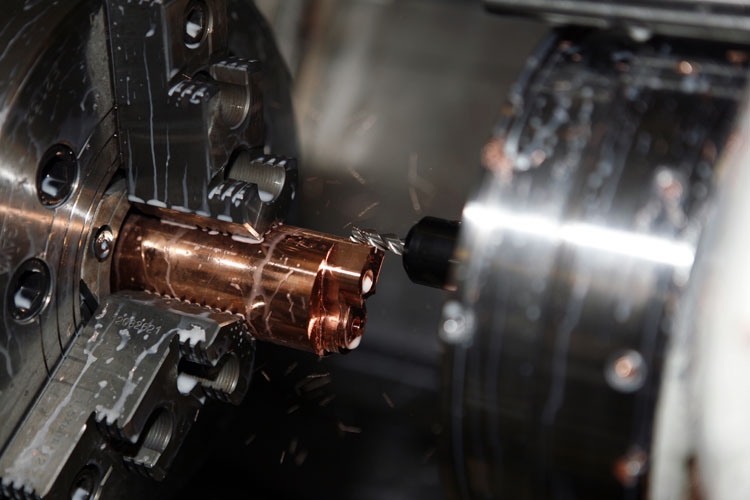

CNC TURNING In the production area of 400 m2, is 7 CNC lathes. Please note that all machines have feeders for the operation of bars (hydro feeders or feeder FMB). The products that we do have a diameter of 2 to 100mm, and the preparation of the bars is to 75mm diameter, the specimens are mostly medium complexity. The materials used to manufacture parts are steel, stainless steel - materials of aluminum, plastic, brass, copper etc. Our CNC machining centers for turning the Mazak, INDEX or WEILER, and photos of machines you can see in our gallery. In the production area of over 200 m2 is located 9 Single-spindle automatic lathes of line brand INDEX A dimension of 2-25 mm. Please note that these machines are used for simpler products and large-sized series, and where a lower price products. maximum specimen size of the bars is 25 mm in diameter and lengths up to 60 mm, and specimens are mostly medium complexity. In the production area of over 220 m2 are located 3 šestvretena automatic channel brand Schütte dimensions 16-20 mm. Please note that these machines are used for simpler products big series, and where a lower price products. The maximum specimen size of rods up to 20 mm diameter and a length of up to 60mm, and the specimens are mainly medium complexity. All machines are fully equipped, and there are all He needs backing machines been successfully monitoring and maintenance production. For finišne works we own machines for milling, drilling, threading and thread rolling, injection. Plan for future investment the multi-axis CNC machining center for milling, turning and milling.

A.D. "Alpro" Vlasenica

Aluminum profiles according to customer requirements Alpro has been producing special profiles for various purposes according to customer's requirements as well as standard profiles for many years. It is possible to produce them from different alloys with or without surface protection . The process of creating a profile according to the customer's design: Step 1 - The customer submits a technical profile drawing or a sample of the desired profile. Step 2 - In case a sample of the desired profile is submitted, Alpro's technical service prepares a drawing that agrees with the customer. Step 3 - When everything is defined on the drawing, the customer receives a quotation and orders the tool. Step 4 - The last step. Production, delivery of the desired profiles according to the customer's requirements. By purchasing tools, the tool is protected. The customer becomes the owner of the tool and only he can create profiles on this tool.

Imaco Systemtechnik d.o.o

SYSTEM DELIVERIESIn order to enable our customers to reduce costs, sometimes considerably, not only in part production and cable assembly, we also offer the assembly of subassemblies and modules.In doing so, we do not only install the materials we manufacture. In close coordination with our customers, we are also happy to take over the procurement of all bought-in parts.As a system supplier, we are the central point of contact for our customers and are responsible for the entire value chain from ordering to acceptance. Of course, we also support our customers beyond the warranty period.We develop and assemble modules, control cabinets and complete machines for our customers.

Tring d.o.o.

PCB PRODUCTIONHigh quality and express delivery PCB from the heart of Europe PCB IntroWe offer a wide range of PCB starting from single and double-sided ones to multilayer (up to 8 layers) with the express delivery times (starting from 24h).Our location (only 50km away from EU) allows the next day express delivery to the most of the Europe and 2-3 days to the rest of the world (by DHL EXPRESS).Starting from 2014 we implement IPC standard and ISO 9001:2015 from 2017. PCB SubcontractingWe partner, as a subcontractor, with the most valuable EMS and PCB related companies around Europe. Our technology and personel experience, continious learning and process optimization, investment in high-tech equipment, partnership with most advanced PCB suppliers, inovative, progressive and "clients-first" business approach, allow us to become a preffered PCB partner. PCB Technology & EquipmentWe partner with the world-class PCB suppliers in order to maintain required PCB quality: MacDermid-Enthone, Atotech, MEC, Isola, Kingboard, Electra, SunChemical, Hitachi Chemicals, Elga, Felder, etc.We have been continuisly investing in the high-tech PCB equipment: Schmoll Maschninen, Pill, Penta, Dynachem, Corema, Mivatec, Cemco. PCB Capabilities and QualityPlease download our PCB capabilities and other related documents. PCB Capabilities ISO 9001:2015

SARAČEVIĆ DOO

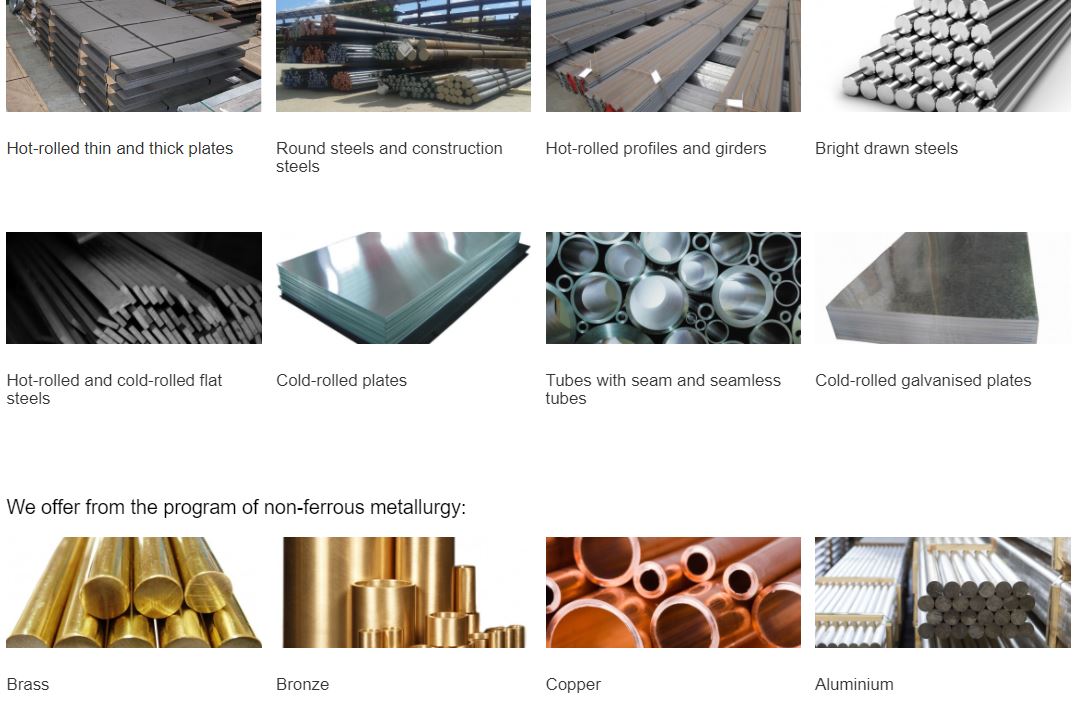

We are able to offer to our buyers wide assortment of products of ferrous and non-ferrous metallurgy with prompt reaction and reliable delivery. In our storage spaces programs of following groups are represented: Hot-rolled thin and thick plates Round steels and construction steels Hot-rolled profiles and girders Bright drawn steels Hot-rolled and cold-rolled flat steels Cold-rolled plates Tubes with seam and seamless tubes Cold-rolled galvanised plates We offer from the program of non-ferrous metallurgy: Brass Bronze Copper Aluminium

ARI Fleet Germany GmbH / ARI Fleet Leasing Germany GmbH

A workshop network you can trust. Repairs and maintenance work in manufacturers' workshops have their price, because quite often they work with methods that only serve their turnover and profit. However, according to the EU Commission (BER 1400/2002), you can have service intervals on your vehicles carried out in independent workshops without losing the material defect liability period or manufacturer's warranty. ARI Fleet has a nationwide network of 1,500 qualified and certified automotive workshops.

Tepcomp Group

Electronic manufacturing services (EMS) of medical devicesTepcomp Group has been manufacturing health care and wellness technology equipment for over thirty years. We have all the necessary knowledge and skills covering the entire production process of demanding medical equipment. Tepcomp is, in particular, known for cost-effective equipment manufacture and uncompromising compliance with requirements. Electronic manufacturing services (EMS) of industrial electronics Tepcomp knows the distinctive features and needs of different industries. We have implemented demanding tailored solutions at our production plants in Turku and Estonia, which often show the efforts of our design and product development team. LED electronics Contract manufacturingTepcomp has implemented versatile and demanding LED lighting projects utilising both passive LED module electronics assembly and integrated power sources. By combining our customers’ expertise with electronics designed by Tepcomp, we have created products of exceptional quality. LED product development and design and LED productsWe offer design of innovative LED power sources and LED circuit boards based on our wide range of products and extensive experience in LED technology development. Tepcomp has extensive experience in the design of LED lighting solutions for mains-powered and low voltage AC and DC systems. Tepcomp’s own product range includes high-quality LED lighting components designed in Finland and based on the latest technology.

Steelprofi

Laser CuttingSheet metal laser cutting is one of the most beneficial ways to produce parts. The fully automated system enables you to produce your components with the highest precision. We offer carbon steel, stainless steel and aluminum cutting. Metal sheet bendingThe latest generation of press-type bending machines allow the most complex bends to be executed and ensure the exact foldability of the fold. WeldingWe offer stainless steel welding up to 4mm thickness. TIG welding provides quality joints. This type of welding does not cause the parts to deform.

Silkeborg Spaantagning Baltic SIA

CNC turning CNC milling CNC gear milling Welding Cutting Assembly Other services Turning Milling Drilling The FMS plant - Flexible Manufacturing System Assembling & Inventory control