Bofill d.o.o. - Products

Weldments and assembled products

The decennial experience as a top-ranking companies provider enabled the development of relevant competencies in the manufacturing of finished assemblies ready made for direct integration into the client’s assembly lines.The certifications achieved allow us to also perform welding of high-strength steels and aluminum. A large machine inventory, made up of CNC machines, TIG, MIG and MAG welding machines, welding robots and projection punching machines allow us to follow the client from design to the finished product and the test.A pivotal role is played by the assembly lines designed to supply the finished product directly to the clients for the delivery to the final market.The competencies and experience achieved allow the Group to support the clients in the new products research and development stage, analyzing the solutions that better suit their requirements.Management tools such as Kanban, Milk-run and the consignment stock allow us to guarantee a high level of service and optimal management of the stocks and of the manufacturing flow for the client.More...

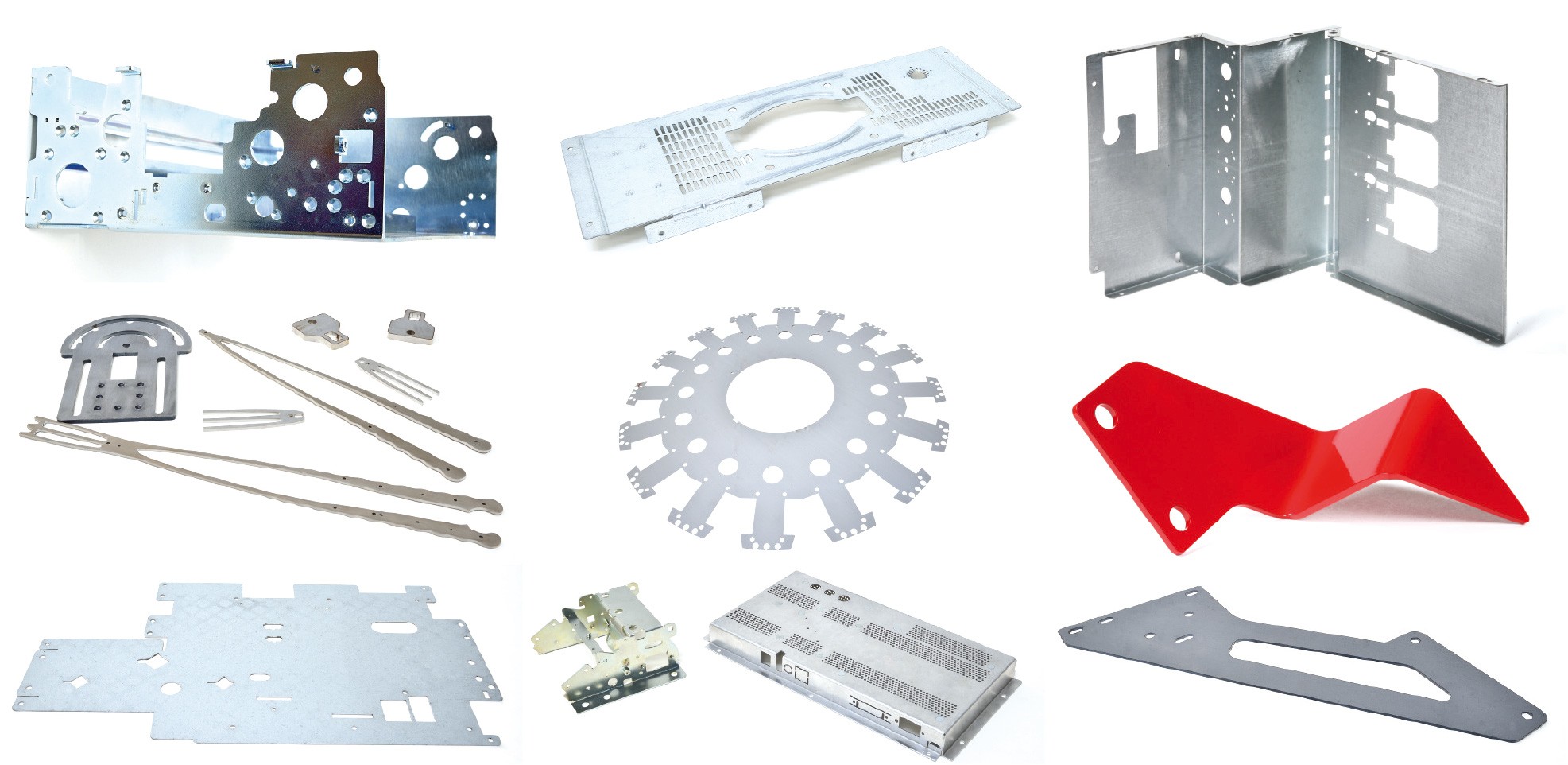

Panelings

The metal punching and paneling lines allow the Boschetti Group to efficiently serve markets such as the office furniture sector, the vending and air-conditioning sector and other markets, providing high-quality levels to the clients. The manufacturing lines enable fully automated sheet metal punching, shearing and folding and are at present recognized as being among the most efficient flexible systems for sheet metal processing (FMS) on the market.The panels made of zinc-coated, aluminum-coated, prepainted sheet metal and other materials may be delivered equipped with internal insulating or soundproof panels. Furthermore, the Group is also capable of internally managing the entire component painting process.Management tools such as Kanban, Milk-run and the consignment stock allow us to guarantee a high level of service and optimal management of the stocks and of the manufacturing flow for the client.More...

Laser cut and folded products

The bond between available technologies and a large range of materials and thicknesses enable the Group to respond to the clients’ requirements, providing an optimal solution for any laser cut and folded component.The available machine inventory, updated with the latest technologies such as the fiber lasers and the folding presses equipped with an automatic tool changer enables the manufacturing of stainless steel, carbon steel and aluminum laser cut and folded components up to 20 mm thick.The fiber lasers allow us to also process copper, brass and aluminum with high-quality cutting. Numerous 8-axes CNC folding presses enable folding of up to 3 meter-long parts.Management tools such as Kanban, Milk-run and the consignment stock allow us to guarantee a high level of service and optimal management of the stocks and of the manufacturing flow for the client.More...