Epalfer - Serralharia de Moldes, Cunhos e Cortantes, Lda. - Products

Products

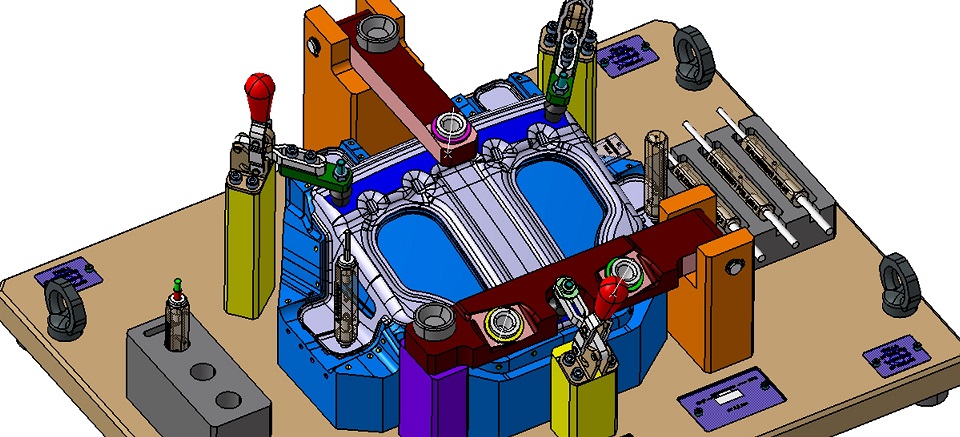

Products PrototypingWe develop with our costumer simulating study to check parts feasibility in early stage. To reproduce real parts, “white tools” or drawing operation for end production tooling is manufactured in short time either for 1 or 1000 parts. Using 5 axis laser cutting and 5 axis machining, we ensure accurate contour of the parts to produce. Progressive ToolingEpalfer is highly experienced with Progressive Tooling from medium to high complex parts up to 1600mm width. We have produced Progressive Tooling with: Tapping units ( vertical/horizontal); Insertion of nuts, screws and bushing; In die “Tox” clinching, etc. Our costumers can expect to achieve the maximum productivity/quality from our progressive tools. TransferTransfer and Tandem tooling are used in medium-sized to large-sized components whose geometry does not allow production in progressive dies. We supply transfer and tandem tooling for presses up to 2000Ton and 6000mm length. We develop and study the Transfer Bars Kinematics or integrate it from another supplier ( example: Springer, Destaco, Misati, etc.). Our main Casting suppliers deliver us casted elements between 5-6 weeks. Welded structures can be produced in 2 weeks. Hybrid ToolsOne of our core business is to develop tools that integrate progressive steps with transfer operations ( Hybrid Tooling ). This way we can minimize material consumption to the minimum for complex geometry parts. Either with standard transfer or mechanical transfer (more strokes per minutes) we develop the best solution for our costumers. FixturesOn request we are able to manage the supply of fixtures and control gauges for the parts produced by our tools.