News

Deutsch-Portugiesische Industrie-und Handelskammer / AHK Portugal

12/19/2020

News

Here we report on the latest in German-Portuguese business life. Read the latest member news, information about Portugal, foreign trade, market information and news from the network. More...

XOM Materials GmbH

12/16/2020

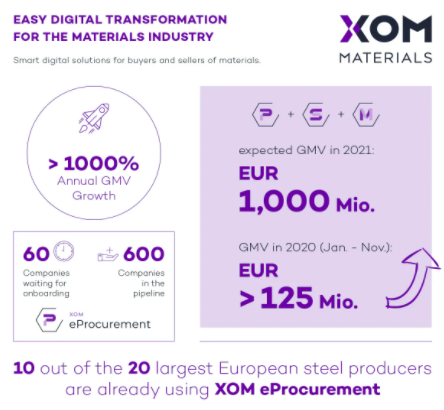

XOM on track to become the leading digital ecosystem for the materials industry

XOM Materials, the digital platform that connects buyers and sellers of materials, has passed the GMV threshold of EUR 100 million and is expecting to reach a GMV of up to EUR one billion in 2021. XOM Materials, the go-to online platform for trading materials such as steel, metals, and plastics, is growing exponentially. The Berlin based company was able to significantly increase the Gross Merchandising Volume (GMV) to over EUR 125 million from January 2020 till end of November 2020 – a growth of more than 1,000% as compared to the previous year period. In 2021, XOM Materials expects a GMV of up to EUR one billion. "COVID crisis and pressure to digitize are pushing many companies to buy and sell online," says Marek Sacha, CEO of XOM Materials. "Our exponential growth shows that we are on the right track to become the leading digital ecosystem for the materials industry”, Mr. Sacha continues. Strong demand for the company's procurement solution The concept of directly connecting sellers and buyers online and shifting large parts of the procurement and selling process for industrial materials into the digital world is meeting with great interest on the market. 10 of the largest 20 European producers are already using XOM eProcurement, over 60 companies are waiting to be onboarded to be able to buy or sell products online. From the beginning of January 2021 XOM will offer the eProcurement Platform in the US and Brazilian markets which is an important step for the company. More...

Comarch AG

12/16/2020

BayWa Implements Comarch EDI to Meet the Upcoming B2G E-invoicing Obligation

In its agriculture, energy and construction segments, the internationally active BayWa AG Group has numerous business partners, the majority of whom are owned by the German government. In view of the obligation to exchange invoices electronically, which comes into force on 27 November 2020, BayWa has chosen the certified IT manufacturer Comarch as its service provider. Comarch EDI enables BayWa to exchange invoices in a legally compliant manner with its mostly state-owned business partners, who are bound by the e-invoicing obligation. With Comarch EDI being a certified PEPPOL Access Point, direct electronic connection to the German e-billing platforms is made via PEPPOL. This includes conversion of the format of all invoices from existing IT systems to XRechnung and subjecting them to verification. Moreover, it provides a consistent protocol for communication with business partners. More...

Wig d.o.o.

7/16/2020

ASTONISHING VERTICAL CALIBRATION OF ALTOSONIC 5 FLOWMETER

For an international oil company, KROHNE manufactured an unique, vertically constructed, fiscal metering system. The design of the metering system is unique due to vertical installation of the metering lines and due to the fact that the Ultrasonic flowmeters will be directly calibrated against a Small Volume Prover. The metering system is equipped with 4 highly accurate ultrasonic ALTOSONIC 5 flowmeters. They are used to perform fiscal measurement of crude oil during batch loading to tankers from an offshore submerged caisson of 48,000 m³ storage capacity. This project combines three unique features and capabilities: 1. Construction of a vertical custody transfer measuring skid with vertically installed ALTOSONIC 5 ultrasonic flowmeters, 2. Initial vertical calibration of the ALTOSONIC 5 ultrasonic flowmeters using Master Meters. 3. Vertical verification of the ALTOSONIC 5 ultrasonic flowmeter against a Small Volume Prover. https://www.youtube.com/watch?v=Ae6vLPgvLXY The custody transfer ALTOSONIC 5 ultrasonic flowmeters have been manufactured at the KROHNE production facility and are compliant with the NPD (Norwegian Petroleum Directorate) quality standards. To ensure and confirm equipment’s performance, the customer requested the flowmeters to be calibrated in a vertical position at the EUROLOOP facility in Rotterdam. The flowmeters were calibrated over the applicable Reynolds range of approximate 80.000 to 1.000.000 at 5 flowrates with 5 repeats using the EuroLoop Master Meters as a reference. The calibration results were compliant to the customer’s requirements defined as: Performance band : ± 0.15 percent over its full operational flow range Uncertainty: 0.027 % following API standards. More...

IDAS d.o.o

7/12/2020

HAAS GR-712 in operation

The HAAS GR-712 milling machine is in operation since the 16th of March 2020, and is since working in two shifts. More...

GOMMA Line d.o.o

7/12/2020

GOMMA Line Russia

GOMMA Line has announced opening of its new 1.200 m2 manufacturing facility in Togliatti in Russia. GOMMA Line has announced opening of its new 1.200 m2 manufacturing facility in Togliatti in Russia. Official opening was on July 2019. The new facility is said to offer a lean, efficient production layout and optimized materials flow. New manufacturing facility is basically relocation from old facility at the same city to SEZ (Special Economic Zone). It is expected to support demand and growth of company customers in Russia and the key mission is to expand company global customer base.

GOMMA Line d.o.o

7/12/2020

Joint venture with M. Huber I.T.Σ.

Increasing our knowledge Increasing our knowledge and gaining new technologies by establishing cooperation and joint venture in the field of tool making with German company M. Huber I.T.Σ. well known for production of injection molding tools for rubber. More...

EMKA FEINGUSS DOO

7/10/2020

Mould making: impressions from Bosnia

EMKA’s locks, hinges, and seals are what both experts and customers alike associate with the company – after all, the company is the world’s market leader in these areas. But since the acquisition of Bekto Precisa in Goražde / Bosnia-Herzegovina, EMKA has become one of the largest mould makers in Europe. We provide exclusive insights into two factories, where more than 700 employees producing 900 moulds per year for internationally known companies. UP TO 900 MOULDS FOR INJECTION MOULDING AND DIE CASTING ANNUALLYEMKA’s locks, hinges, and seals are what both experts and customers alike associate with the company – after all, the company is the world’s market leader in these areas. But since the acquisition of Bekto Precisa in Goražde / Bosnia-Herzegovina, EMKA has become one of the largest mould makers in Europe. We provide exclusive insights into two factories, where more than 700 employees producing 900 moulds per year for internationally known companies. Meanwhile, Goražde has become one of the largest EMKA locations worldwide. More than 150 colleagues are directly employed in mould making, 46 engineers work in development, design and CNC programming. Above all, the appearance and infrastructure on-site have changed significantly, as the original plant was completely rebuilt only 5 km away from the previous location. In addition, EMKA bought a large plant for mould making, so that today 55,000 m2 are available for production and development. Both plants are located within close proximity. The employees can rely on more than 100 state-of-the-art machines. Whether zinc die casting, aluminium die casting, stainless steel investment casting or plastic injection moulding: on the one hand, the wide range of machinery enables the production of own products in the catalogue programme; on the other hand, EMKA sees itself as a bilateral development partner of its customers. Thus, EMKA is able to produce prototypes, first samples, and pilot series as well as large series up to complex assemblies from all mentioned materials in job order production. Among the end-users of this resource strength are well-known industry giants such as Mercedes, Audi, Porsche, and Fischer Sports (Ski), who can have up to 900 moulds and the resulting products manufactured by EMKA every year. More...

EMKA FEINGUSS DOO

7/10/2020

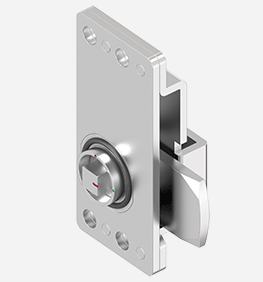

Program 1001 Safety cam lock with marking

Safety cam lock with markingFlush mounted assembly for doors and flaps with a thickness of 5 mm. As the safety cam lock is vibration-proof, it fulfills DIN EN 61373 and therewith it is ideal for use in the railway vehicle industry. Product description / product benefits Opening indication with red / green marking Available with inserts hexagon female 8 mm and square 8mm with marking Tested to IP 65 Flush mounted at door thickness of 5 mm Vibration-proof according to DIN EN 61373 Safety cam lock made from AISI 304 More... Online-catalogue PDF-catalogue page B1-810

BWC Group

7/10/2020

FILTECH 2019

BWC team visited FILTECH 2019, the most important international fair on field of filtration and separation. More than 400 exhibitors, more than 16.500 participants from the whole world. Our long-year partners, but also prospective partners were in our focus. Visit of FILTECH is the best way to follow changes and development, which are extremely dynamic in this field. Positive market trends are the most important impressions from FILTECH 2019. So, until FILTECH 2021, we are facing new bussiness goals and challenges. More...

Lederer GmbH

6/16/2020

Never start rusting in the future either!

2020 is an anniversary year for Lederer GmbH: The specialist for stainless fasteners and standard parts as well as efficient C-parts management is celebrating its 50th anniversary. The family-owned company from Ennepetal has long been one of the market leaders in the industry and is expanding its business with new investments. The company was founded on January 2nd, 1970 by Rainer Lederer and a business partner. It quickly established itself in the growing market for stainless steel fasteners and increased its number of employees from five initially to more than 200. Dr Volker Lederer, who is the second generation to lead the AEO-F certified company at its headquarters in Ennepetal, has done so since 2010. The core area was the retail trade business for many years until the industrial sector was established and expanded as a new business area in the 1990s. The Lederer range includes special parts by drawing, manufacturer-specific C-parts, packaging, labelling and assembly, as well as complex logistics and Kanban solutions (also RFID-based). Ahead in digitisation Lederer GmbH is characterised primarily by short response times, a worldwide procurement network and fast delivery. In addition, customers from home and abroad also appreciate the mixture of many years of experience, personal support and sophisticated digital processes. This includes e.g. the use of RFID technology in the field of C-parts management. Thanks to this almost fail-safe and contactless transmission/reception technology, the transmission of requirements required in Kanban systems is almost instantaneous. This saves time and ensures more process reliability. In addition, Lederer offers its own online shop with live availability and prices, EDI interfaces and new cloud solutions for customer-specific information and document exchange. Accredited test laboratory according to ISO/IEC 17025 In addition to its in-house testing department, which is responsible for the standard incoming and outgoing goods inspections, the company also has its own ISO/IEC 17025-accredited test laboratory. Complex tests such as tensile tests and salt spray tests carried out to ensure the highest possible quality level. The results are documented in corresponding test certificates and test reports. Further investments planned With an eight-figure investment in the company's infrastructure, the course for the future has been set in recent years: among other things, investments have been made in the new building for logistics, packaging and outgoing goods as well as the automatic small parts warehouse, which will provide almost 60,000 locations in the future. The expansion of the automatic small parts warehouse and the conveyor technology means a further increase in capacity and speed in picking and shipping. For Volker Lederer it is clear: “We do not want to start rusting in the future but want to start this anniversary year with concrete further developments.”

costdata GmbH

6/2/2020

costdata opens the first online shop for market data worldwide

costdata hits the nerve of the time with the world's first online shop for industrial market data. Although it was already possible to get access to extensive databases or single compiled datasets, this turned out to be costly and above all very time-consuming. The new platform makes it possible to obtain the desired data almost in real time. For each of the more than 3,000 regions, 10 wage and salary levels are available for 15 sectors, including all ancillary personnel costs as well as location cost factors such as prices for electricity, water, steam, compressed air and cost of premises. In addition, there are over 28,000 raw material prices, more than 11,500 machine data with prices and a comprehensive range of overhead factors. At costdata, the world's largest provider of cost data, we are aware of the importance of industrial market data. For more than 20 years now, the company, which has made a name for itself mainly with calculatory software solutions and consulting services, has been collecting all the data necessary for cost analysis. But what exactly are these data needed for? Due to the increased price and cost pressure in almost all industries, more and more companies are demanding ever more detailed cost breakdowns, both internally and from their suppliers. Today, many companies calculate not only the costs of their own products, but also those of their suppliers. This development, which began in the automotive industry three decades ago, is now an integral part of a large number of companies in the manufacturing industry. "Nowadays it is no longer enough to ask for three offers and decide for the cheapest one", explains Frank Weinert, founder and managing director of costdata GmbH. Why is it clear: "Just because an offer is supposedly the cheapest does not mean that it is fair and best for both sides", the former buyer continues. Complete cost transparency is required to gauge this market attitude and subsequently negotiate better. And in return it requires one thing above all: accurate data. Although software programs for cost calculation have now largely replaced the self-built Excel spreadsheets and worn out reference value booklets, these need to be fed with input. "The accuracy of a calculation stands and falls with the quality of data. If the wrong figures are used from the outset, it does not matter how much expertise the user brings to the table or how sophisticated his calculation tool is," says Weinert. This should now come to an end: "Of course we are happy if even more companies decide to use our software, but our main concern is to create transparency in the entire value-added chain, regardless of which program is used". This is exactly what the new online shop for market data is designed to achieve: by using the market data as a comparison to the actual cost calculation can the competitiveness in your own company and that of your suppliers be checked. Finally, costdata offers its customers a guarantee for data accuracy: if the purchased data should demonstrably differ from their actual values, the customer will get money back immediately.