HSTEC d.d. - Offers

HSTEC d.d.

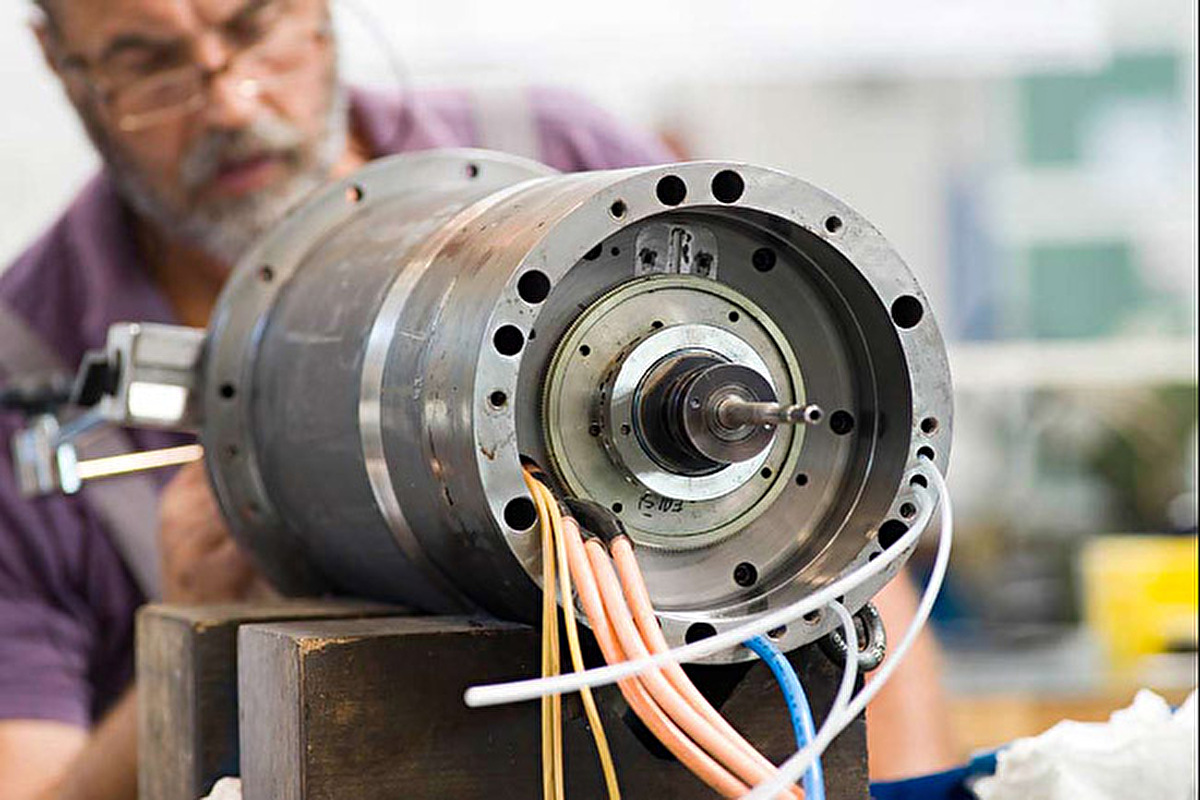

Small batch production of high precision machine parts HSTEC offers small batch production of high precision custom machined parts. Our production department consists of high-precision four- and five-axis machining centers, CNC lathes, cylindrical and planar grinding machines, and coordinate measuring machines. For prototyp part production the newest laser welding device and 3D printing machine are used.New technologies, air-conditioned spaces and controlled working conditions provide high-precision manufacturing and superior product quality. Assembly and product testingOur product assembly and product testing department uses high-tech testing devices and equipment, balancing test stations, high-frequency regulators, and various dedicated test stations.

HSTEC d.d.

Spindle service and repairs HSTec offers service, repairs, redesign and optimization of spindles and motorized spindles of all global manufacturers. Based on years of experience in development and production of innovative high-speed motorized spindles we became leading experts for repairs and optimization of motorized spindles, belt-driven and direct-driven spindles for various applications: grinding, milling, turning, boring. Our department for spindle service and repairs is equipped with a modern welding device for repairing damaged parts, numerous CNC machine tools, lathes and highly precise grinding machines. Various test and diagnostic equipment is used, namely spindle vibration analysis equipment - Hofmann and SKF, high-voltage insulation testing of stator windings - Baker, testing equipment of accuracy and precision of various sensor types such as high resolution motor speed and position sensor and incremental and absolute encoders (Heidenhain, Lenord Bauer, VS-Senzorik, Siemens). We offer complete refurbishment of damaged spindle parts such as HSK and SK cones, bearings and more.